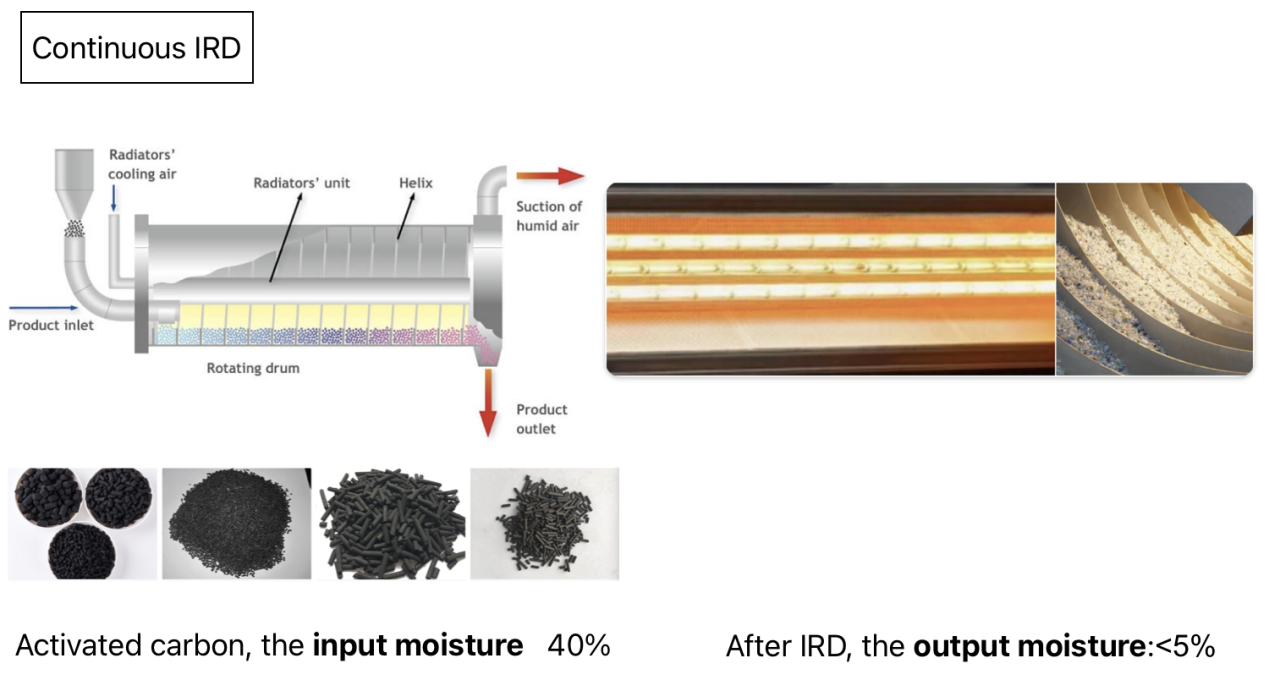

Activated carbon Infrared Rotary Dryer

Product Details

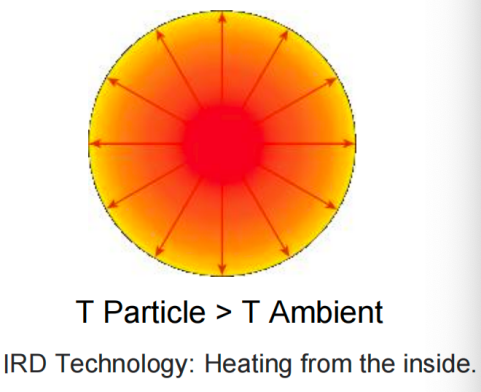

The infrared rays that penetrate and reflect from the material do not affect the organization of the material, but the absorbed tissue will be converted into heat energy due to molecular excitation, which causes the temperature of the material to rise quickly.

Heat to the core. By means of short-wave infrared light the material is heated directly from the inside

From the Inside to the outside. The energy in the core heats the material from the inside out, so the moisture is driven from the inside to the outside of the material .

Evaporation of moisture. The additional air circulation inside the dryer removes the evaporated moisture from the material.

What you care in the production

Always in motion

>> No segregation of products with different bulk densities

>> The permanent rotation of the drum keeps the material moving, each material will be dried evenly

Instant start and quicker shut down

>> An immediate start of the production run is possible immediately upon startup. A warm-up phase of the machine is not required

>> Processing can be started, stopped and restarted easily

Drying in minutes ---20-25mins moisture from 40% to <5%

>> Infrared rays cause molecular thermal oscillations, which directly act on the core of the particles from the inside out, so that the moisture inside the particles is rapidly heated and evaporated into thr circulating ambient air and the moisture is removed at the same time

Lower energy cost

>> Today LIANDA IRD users are reporting energy cost as 0.06kwh/kg, without sacrificing product quality

Easy cleaned and change materials

>> The drum with the simple mixing elements has no hidden sports and can be cleaned easily by a vacuum cleaner or compressed ai

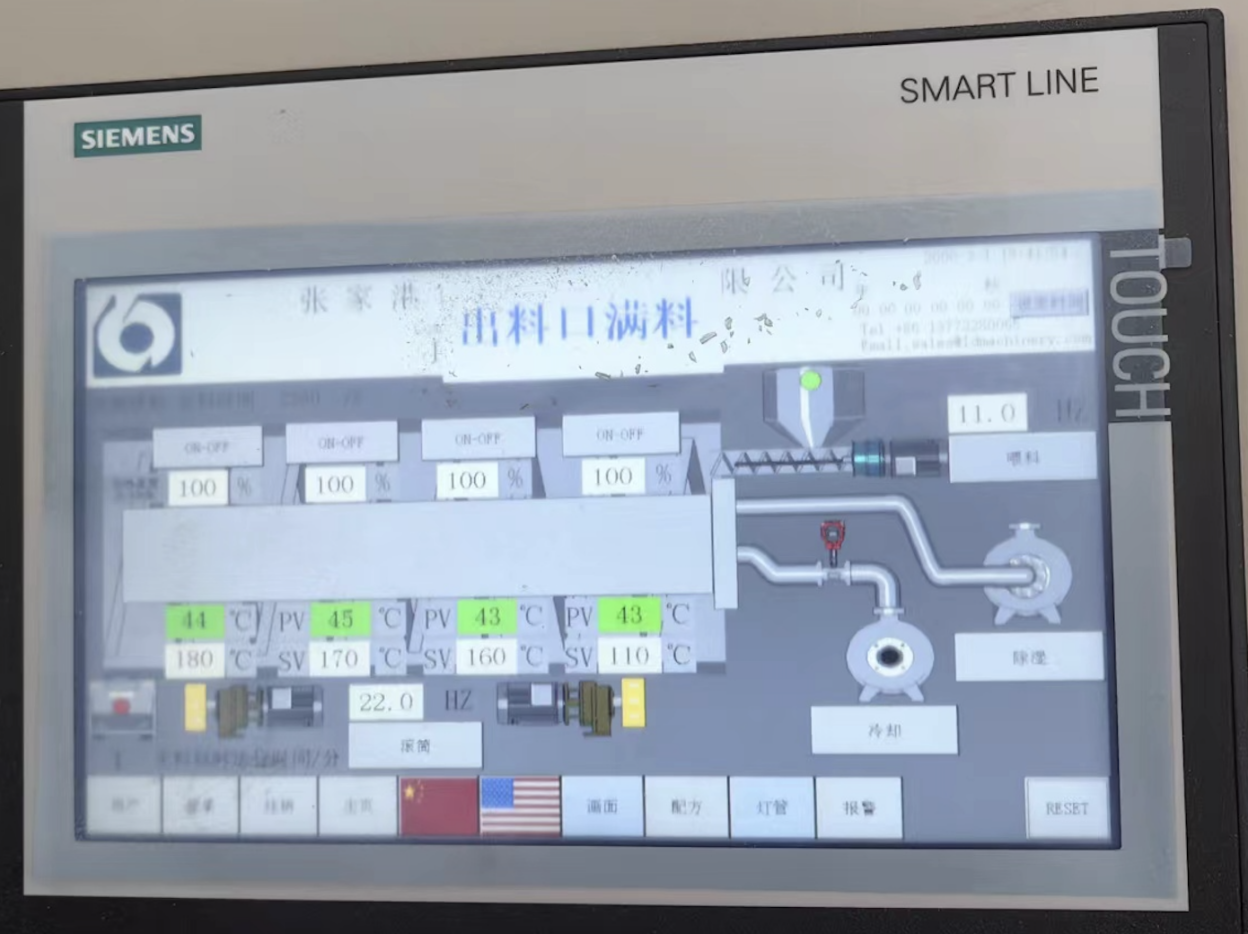

PLC Control

>> Recipes and process parameters can be stored in the controlling system to ensure opimal and reproducble results

Machine photos

Our Service

Our factory has build Test Center. In our Test center, we can perform continuous or discontinuous experiments for customer’s sample material. Our equipment is furnished with comprehensive automation and measurement technology.

- We can demonstrate --- Conveying/Loading, Drying& Crystallization, Discharging.

- Drying and crystallization of material to determine residual moisture, residence time, energy input and material properties.

- We can also demonstrate performance by subcontracting for smaller batches.

- In accordance with your material and production requirements, we can map out a plan with you.

Experienced engineer will make the test. Your employees are cordially invited to participate in our joint trails. Thus you have both the possibility to contribute actively and the opportunity to actually see our products in operation.