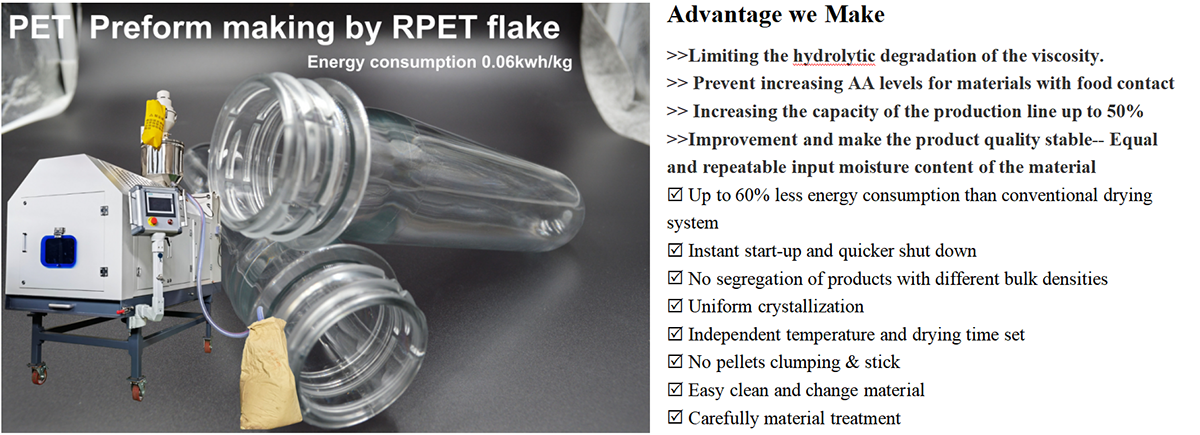

Solutions for the manufacturing of qualitative preforms and bottles made of PET virgin and R-PET resins

1) Energy Consumption

Today, LIANDA IRD users are reporting energy cost as 0.06kwh/kg, without sacrificing product quality.

2) Total process visibility that the IRD system PLC controls make possible

3) To achieve 50ppm only IRD is enough by 20mins Drying&crystallization in one step

4) Widely application

IRD adopt rotary drying system--- very good mixing behaviour of the material+ Special program design (Even stick resin can be dried well and even crystallization )

Post time: Apr-07-2023