Best quality Film Crusher - Plastic Bottle Crusher/PET Bottle Crusher/Plastic Crusher/ Plastic grinder/Plastic shredder, Plastic water bottle crusher – LIANDA

Best quality Film Crusher - Plastic Bottle Crusher/PET Bottle Crusher/Plastic Crusher/ Plastic grinder/Plastic shredder, Plastic water bottle crusher – LIANDA Detail:

Hollow plastic Crusher — LIANDA Design

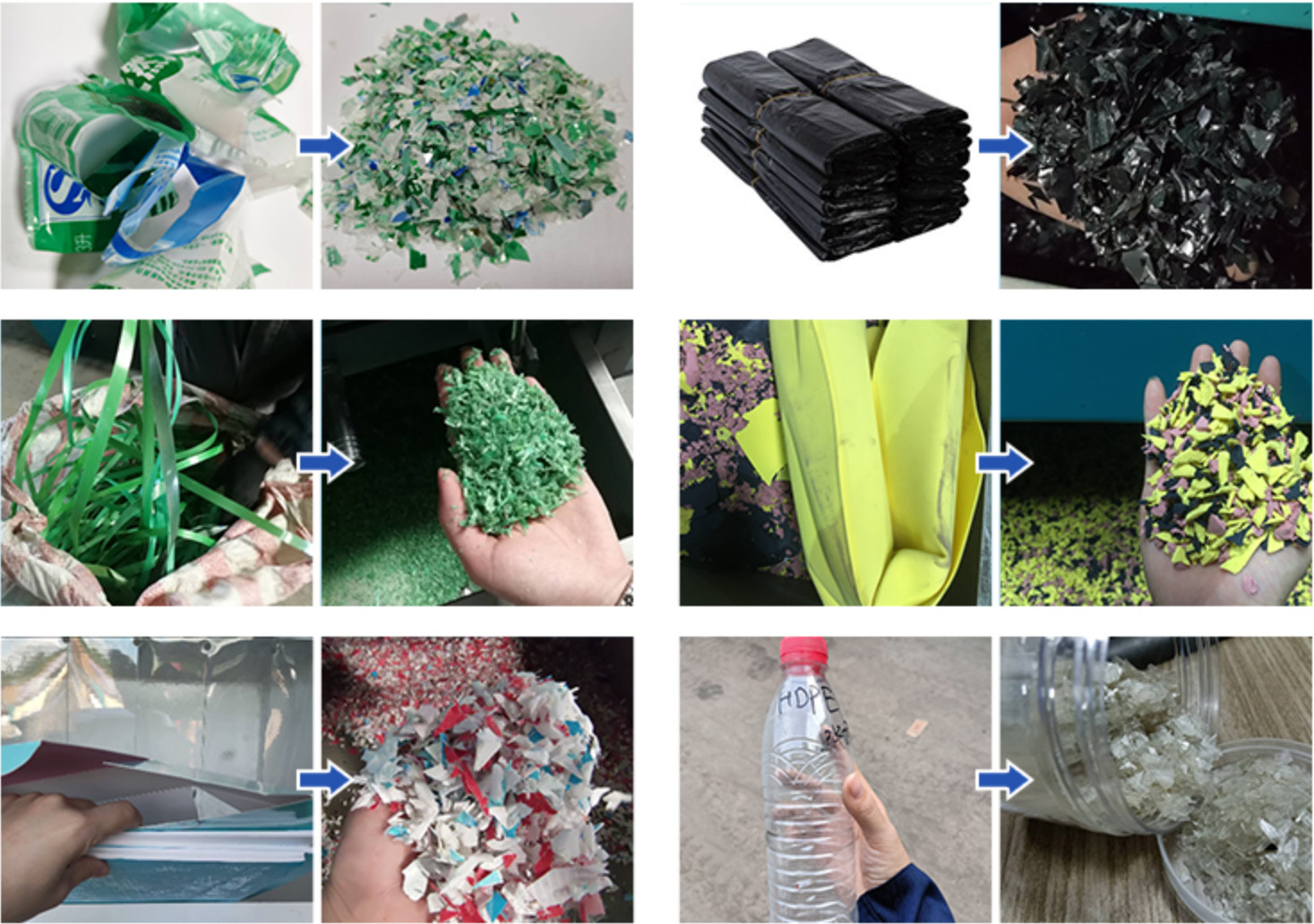

>>Plastic Bottle Crusher/ Granulator is designed and manufactured for processing hollow plastics, such as HDPE milk bottles, PET beverage bottles, Coke bottles, etc.

The knife holder structure adopts a hollow knife structure design, which can better cut hollow plastics during crushing. The output is 2 times higher than the ordinary crusher of the same model, and it is suitable for wet and dry crushing. It is an indispensable special equipment in the plastic bottle recycling and processing industry

It is also ideal machine for the secondary cutting when positioned behind pre-shredders of recycling systems.

Machine Details Shown

Blade Frame Design

>> Special designed blade frame which can better cut hollow plastics during crushing.

>> The output is 2 times higher than the ordinary crusher of the same model, and it is suitable for wet and dry crushing.

>>All spindles have passed strict dynamic and static balance tests to ensure the reliability of machine operation.

>>The spindle design can be customized according to different material requirements.

Charming Room

>>The design of the plastic bottle crusher is reasonable, and the body is welded with high-performance steel;

>>Adopt high-strength screws to fasten, solid structure and durable.

External bearing seat

>> The main shaft and the machine body are sealed by sealing ring, effectively avoid the casing of the crushing of material into the bearing, improve the bearing life

>> Suitable for wet and dry crushing.

Crusher open

>>Adopt Hydraulic open.

Hydraulic tipping device can efficiently, safely and quickly improve the blade sharpening work;

>>Convenient for machine maintenance and the replacement of blades

>>Optional:the screen bracket are hydraulically controlled

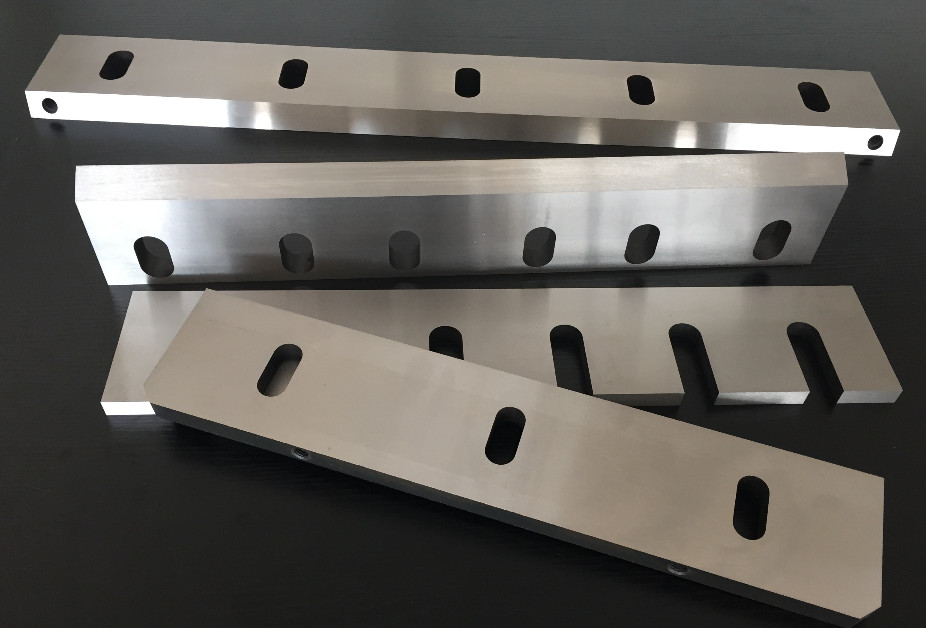

Crusher Blades

>> Blades material can be 9CrSi, SKD-11, D2 or customized

>>Special blade making processing to improve the blades working time

Sieve Screen

>>The crushed flake/scrap size are uniform and the loss is small. Multiple screens can be replaced at the same time to meet different needs

Machine Technical Parameter

|

ITEM

|

UNIT |

600 |

900 |

1200 |

1600 |

|

Rotor Diameter |

mm |

φ450 |

φ550 |

φ550 |

Φ650 |

|

Rotary blades |

pcs |

6 |

9 |

12 |

16 |

|

Stable blades |

pcs |

2 |

4 |

4 |

8 |

|

Motor Power |

kw |

22 |

45 |

90 |

110 |

|

Capacity |

kg/h |

300 |

500 |

1000 |

2000kg/h |

Application Samples shown

Machine Installation

MACHINE FEATURES>>

>>Anti-wear machine housing

>>Claw type rotor configuration for films

>>Suitable for wet and dry granulation.

>>20-40% additional throughput

>>Heavy duty bearings

>>Oversized external bearing housings

>>Knives are externally adjustable

>>Robust welded steel construction

>>Wide choice of rotor variations

>>Electrical hydraulic control to open housing

>>Electrical hydraulic control to open screen cradle

>>Replaceable wear plates

>>Amp meter control

OPTIONS>>

>> Extra flywheel

>> Double infeed hopper roller feeder

>> Blade material 9CrSi, SKD-11, D2 or customized

>> Mounted screw feeder in hopper

>> Metal detector

>> Increased motor driven

>>Hydraulic controlled sieve screen

Machine Photos

Product detail pictures:

Related Product Guide:

We will make every effort to be outstanding and perfect, and accelerate our steps for standing in the rank of international top-grade and high-tech enterprises for Best quality Film Crusher - Plastic Bottle Crusher/PET Bottle Crusher/Plastic Crusher/ Plastic grinder/Plastic shredder, Plastic water bottle crusher – LIANDA, The product will supply to all over the world, such as: Nepal, Nicaragua, Saudi Arabia, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our goods. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for you personally always.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.