Factory directly Plastic Chipper Shredder - Double shaft shredder/Twin-shaft shredder/Solid Waste Double Shaft Shredder Machine – LIANDA

Factory directly Plastic Chipper Shredder - Double shaft shredder/Twin-shaft shredder/Solid Waste Double Shaft Shredder Machine – LIANDA Detail:

Double shaft shredder

Double shaft shredder is a highly versatile machine. The high-torque shearing technology design can meet the waste recycling requirements and is suitable for shredding large volume materials, such as car shells, tires, metal barrels, scrap aluminum, scrap steel, household garbage, hazardous waste, industrial garbage, etc. It can be designed according to customer needs and processed materials to maximize users’ benefits.

>> The machine has the characteristics of large transmission torque, reliable connection, low speed, low noise, and low maintenance cost. The electrical part is controlled by Siemens PLC program, with automatic detection of overload protection. The main electrical The components adopt well-known brands such as Schneider, Siemens, ABB, etc.

Machine Details Shown

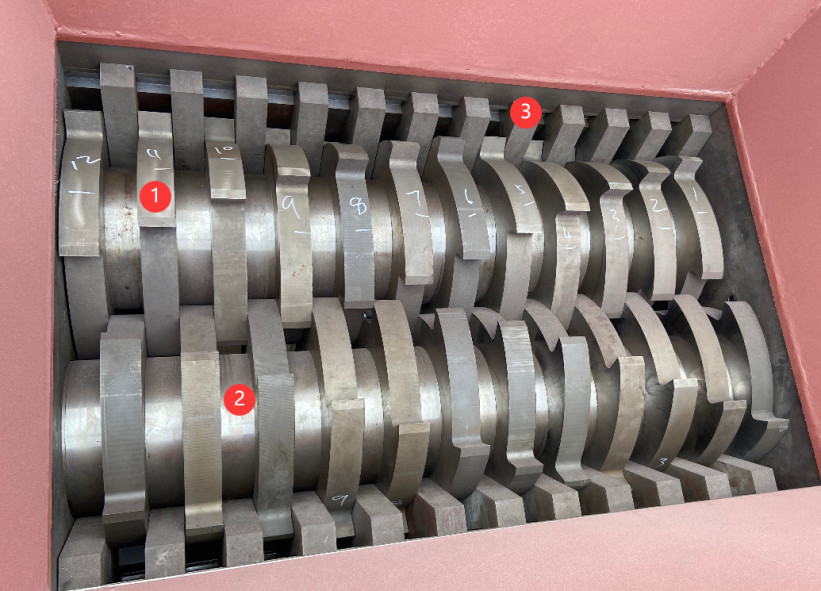

>>Blade shaft Component

①Rotary blades: cutting materials

②Spacer: Control the gap of rotary blades

③Fixed blades: prevent materials from wrapping around the blade shaft

>>Different material adopt different blade rotor model

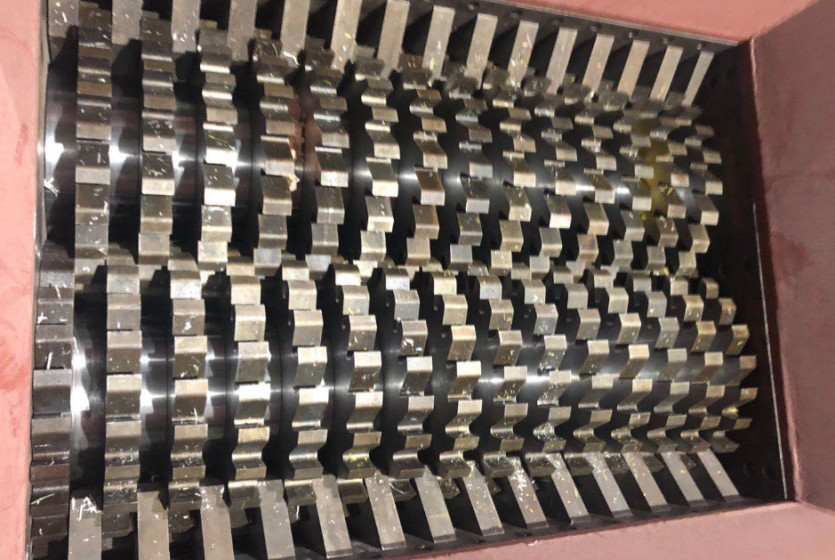

>>The blades are arranged in a spiral line to realize efficient cutting

>>Different material adopt different blade rotor model

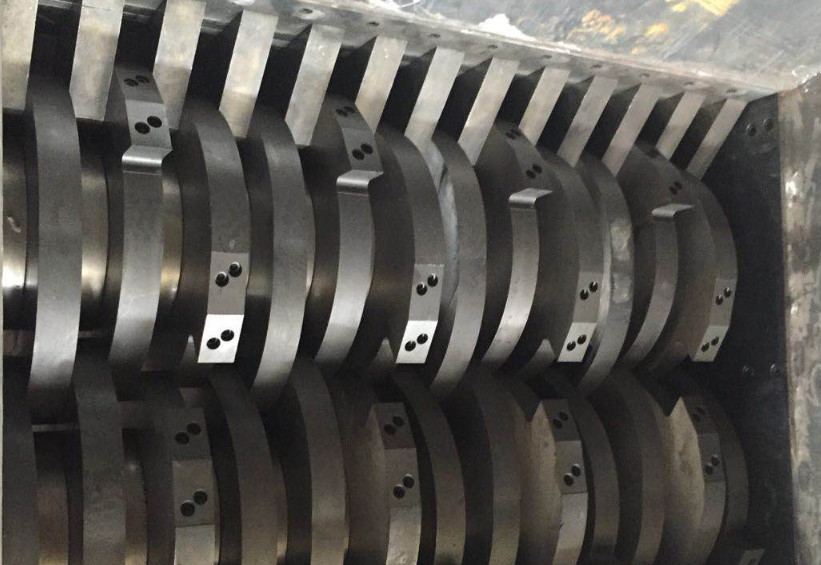

>>Both the inner hole of the tool and the spindle surface adopt a hexagonal design to realize the uniformity of the blade force.

>>Split bearing seat design to facilitate bearing and rotor maintenance

>>The bearing is sealed, effectively waterproof and dustproof.

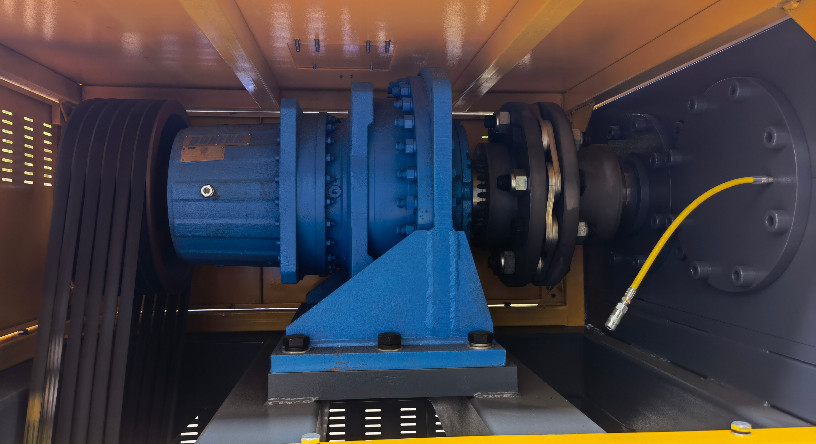

>>Adopt planetary gear reducer, smooth running and shock resistant

>>Siemens PLC monitors the motor current in real time, and the knife axis automatically reverses when the load is overloaded to protect the motor;

Machine Technical Parameter

|

Model

|

LDSZ-600 |

LDSZ-800 |

LDSZ-1000 |

LDSZ-1200 |

LDSZ-1600 |

|

Main motor power KW |

18.5*2 |

22*2 |

45*2 |

55*2 |

75*2 |

|

Capacity KG/H |

800 |

1000 |

2000 |

3000 |

5000 |

|

Dimension mm |

2960*880*2300 |

3160*900*2400 |

3360*980*2500

|

3760*1000*2550 |

4160*1080*2600 |

|

Weight KG |

3800 |

4800 |

7000 |

1600 |

12000 |

Application Samples

Car wheel hub

Electrical Wire

Waste tire

Metal drum

MACHINE FEATURES>>

>>Integral knife box design, stable and reliable

Integral knife box, annealing treatment after welding, to ensure better mechanical strength; At the same time, the use of NUMERICAL control machining, to ensure higher processing accuracy, prolong the service life of equipment, saving maintenance costs.

>>The fixed knife is independent and removable, with strong wear resistance

Each fixed knife can be independently disassembled and installed, which can be disassembled in a short time, greatly reducing the workload of workers and improving the continuity of production.

>>Unique blades design, easy to maintain and replace

The cutting blades are made of imported alloy steel with long service life and good interchangeability, which is easy to maintain and replace the cutting tool in the later period.

>>The spindle strength, fatigue resistance and impact resistance

The spindle is made of high-strength alloy steel, which has been heat treated for many times and processed with high precision. It has good mechanical strength, strong resistance to fatigue and impact and long service life.

>> Imported bearings, multiple combined seals

Imported bearings and multiple combined seals, high load resistance, long service life, dustproof, waterproof and antifouling, to ensure the continuous and stable operation of the machine.

Machine Photos

Product detail pictures:

Related Product Guide:

Our purpose is to fulfill our clients by offering golden company, great price and premium quality for Factory directly Plastic Chipper Shredder - Double shaft shredder/Twin-shaft shredder/Solid Waste Double Shaft Shredder Machine – LIANDA, The product will supply to all over the world, such as: San Diego, Bahamas, Panama, Our products have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll provide the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.