Factory Price Pla Dryer - PET Flake/scrap dehumidifier crystallizer/Infrared Rotary Dryer/Plastic dehumidifier/ Plastic Desiccant Dehumidifier/Plastic dryer/Infrared crystal dryer – LIANDA

Factory Price Pla Dryer - PET Flake/scrap dehumidifier crystallizer/Infrared Rotary Dryer/Plastic dehumidifier/ Plastic Desiccant Dehumidifier/Plastic dryer/Infrared crystal dryer – LIANDA Detail:

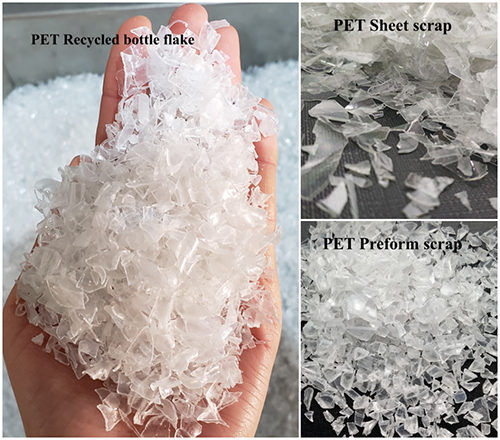

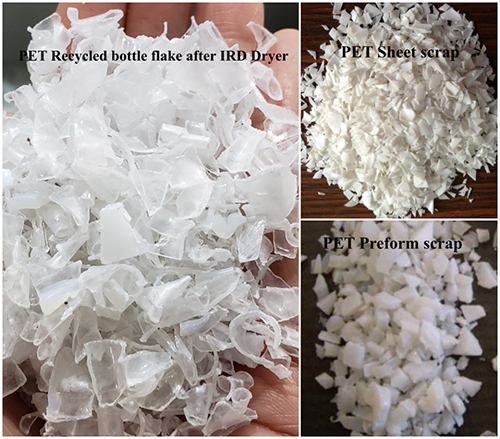

Application Sample

| Raw Material | PET Recycled flake/ PET sheet scrap/PET Preform scrap |

|

| Using Machine | LDHW-600*1000 |  |

| Drying& Crystallized Temperature set | 180-200℃Can be adjustable by property of rawmaterial | |

| Crystallized time set | 20mins | |

| Final material | Crystallized and Dried PET scraps and final moisture can be about 30ppm |  |

How to Work

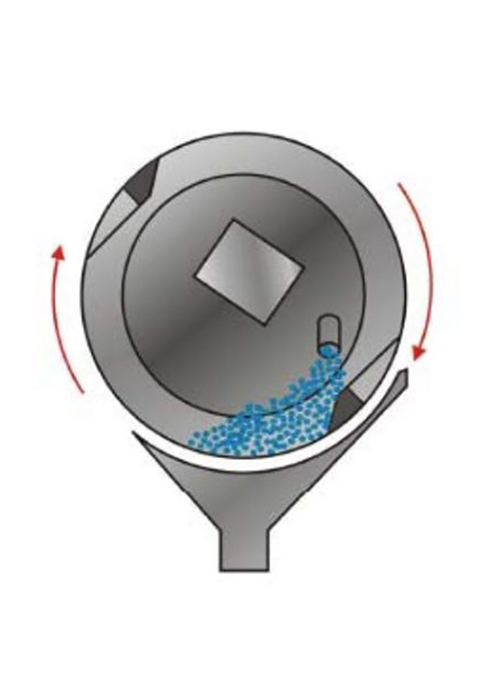

Feeding/Loading

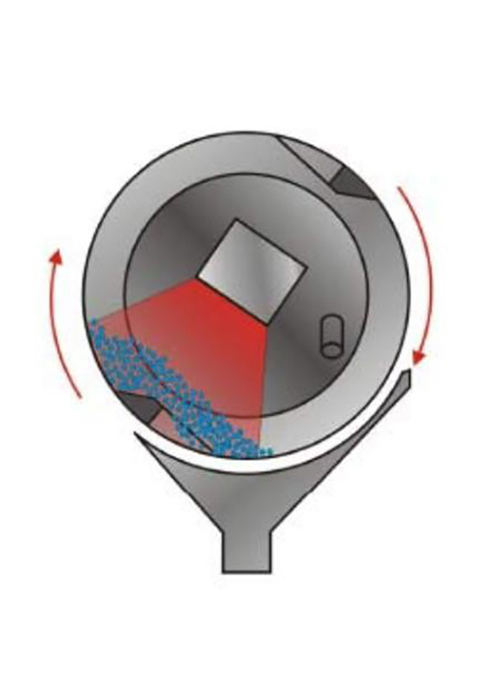

Dry& Crystallization Processing

Discharging

>>At first step, the only target is to heat up the material to a preset temperature.

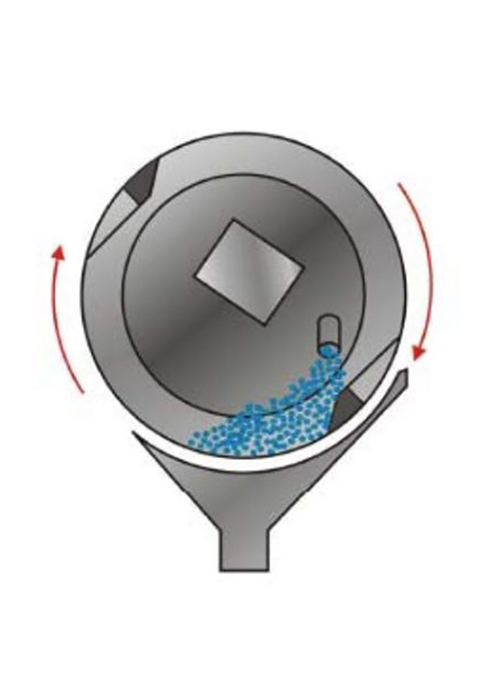

Adopt relatively slow speed of drum rotating, the Infrared lamps power of the dryer will be at a higher level, then the PET pellets will have a fast heating till the temperature rises to the preset temperature.

>>Drying &Crystallizing step

Once the material gets to the temperature, the speed of the drum will be increased to a much higher rotating speed to avoid the clumping of the material. At the same time, the infrared lamps power will be increased again to finish the drying. Then the drum rotating speed will be slowed down again. Normally the drying process will be finished after 15-20mins. (The exact time depends on the property of material)

>>After finishing the drying processing, the IR Drum will automatically discharge the material and refill the drum for the next cycle.

The automatic refilling as well as all relevant parameters for the different temperature ramps is fully integrated in the state-of-the-art Touch Screen control. Once parameters and temperature profiles are found for a specific material, theses settings can be saved as recipes in the control system.

Our Advantage

Normally the PET Bottle flakes or sheet scrap with initial moisture level of up to 10000-13000ppm. The PET Bottle flakes or sheet scrap (Virgin or mixed ) will be recrystallized in Infrared crystal dryer in 20mins, the drying temperature will be 150-180℃ and dried to 50-70ppm,then fed to Single screw extruding system for further processing

● Limiting the hydrolytic degradation of the viscosity.

● Prevent increasing AA levels for materials with food contact

● Increasing the capacity of the production line up to 50%

● Improvement and make the product quality stable– Equal and repeatable input moisture content of the material

Comparison Table

|

Item |

IRD Dryer |

Conventional Dryer |

|

Transfer medium |

None |

Hot air |

|

Heat transfer |

Both inside & outside particles together. | From outside to inside particle gradually. |

|

Energy |

Save at least 20~50% energy compared to traditional dryer. | Consume much energy. |

|

Process time |

1. Crystallization & drying: They are processed simultaneously within about 8~15 minutes. 2. Drying and crystallization at a time |

1. Crystallization: About 30~60 minutes. 2. Drying: About 4~6 hours. |

|

Moisturecontent |

1. Under 50-70 PPM after IRD processed. | 1. Spend 30~60 minutes to change amorphous PET to crystallized PET first. 2. Under 200PPM after about 4 hours dehumidifier processed. 3. Under 50 PPM after about more than 6 hours dehumidifier processed. |

|

Lead time |

20mins | More than 6 hours. |

|

Material changeover |

1. Easy & faster. 2. There are only 1~1.5 times capacity of material hourly consumption in the buffer hopper. |

1. Difficult & slowly. 2. There are 5~7 times capacity of material hourly consumption in the crystallizer & hopper. |

|

Operation |

Simple— By Siemens PLC control

|

It is difficult such as it must put a little crystallized PET in the crystallizer when beginning operation. |

|

Maintenance |

1. Simple. 2. Lower maintenance cost. |

1. Difficult. 2. Higher maintenance cost. |

Machine Photos

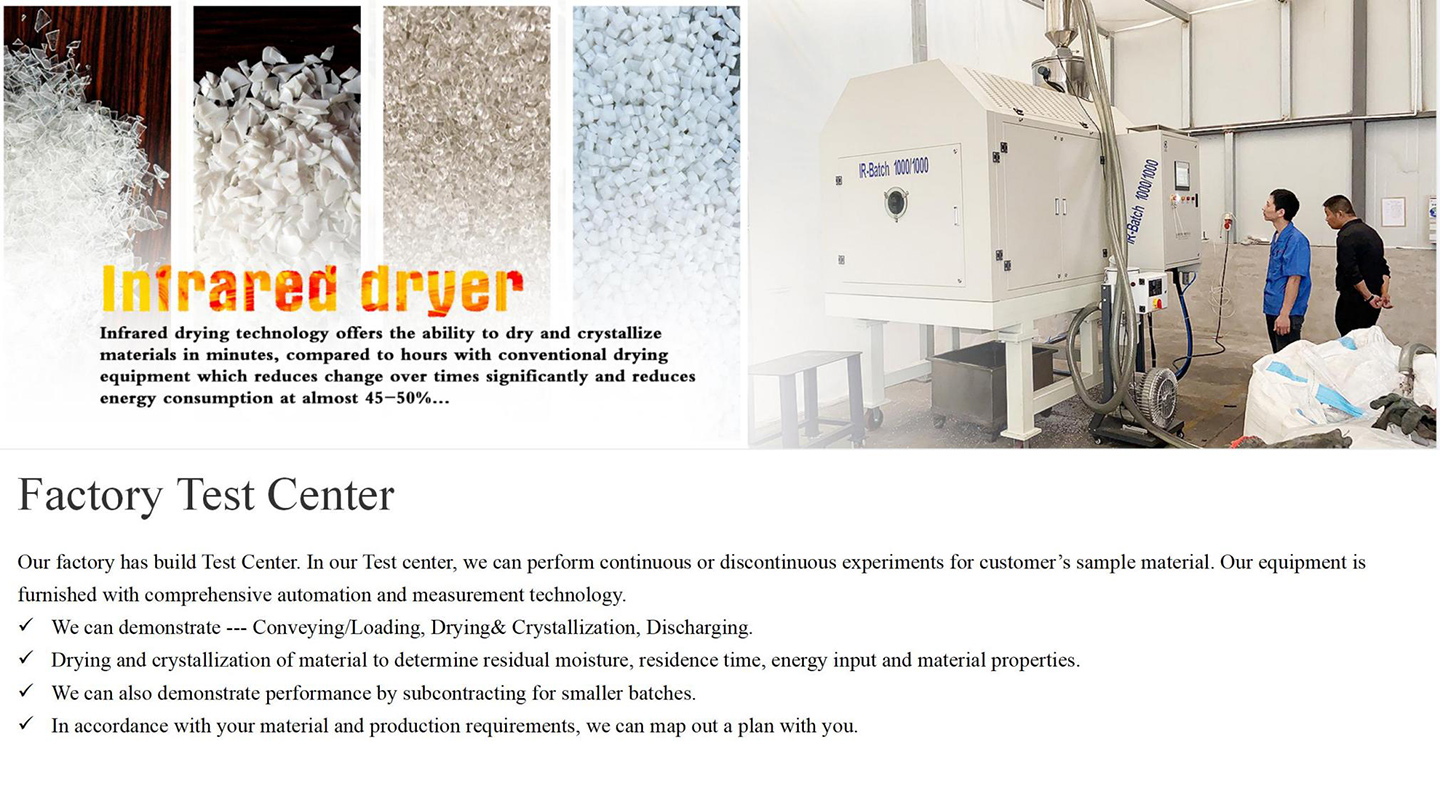

Material Free Testing

Experienced engineer will make the test. Your employees are cordially invited to participate in our joint trails. Thus you have both the possibility to contribute actively and the opportunity to actually see our products in operation.

Machine Installation

>> Supply Experienced engineer to your factory to help installation and material test running

>> Adopt aviation plug, no need to connect the electrical wire while the customer get the machine in his factory. To simplify the installation step

>> Supply the operation video for installation and running guide

>>Support on line service

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our firm's intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for Factory Price Pla Dryer - PET Flake/scrap dehumidifier crystallizer/Infrared Rotary Dryer/Plastic dehumidifier/ Plastic Desiccant Dehumidifier/Plastic dryer/Infrared crystal dryer – LIANDA, The product will supply to all over the world, such as: Iceland, Angola, America, Immediate and expert after-sale service supplied by our consultant group has happy our buyers. Comprehensive Info and parameters from the merchandise will probably be sent to you for any comprehensive acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.