Infrared crystal bushewa don R-PET Pelletizing/ Extrusion Line

Infrared Pre-Bushewa na PET Flakes: Haɓaka Fitarwa da Inganta Inganci akan PET Extruders

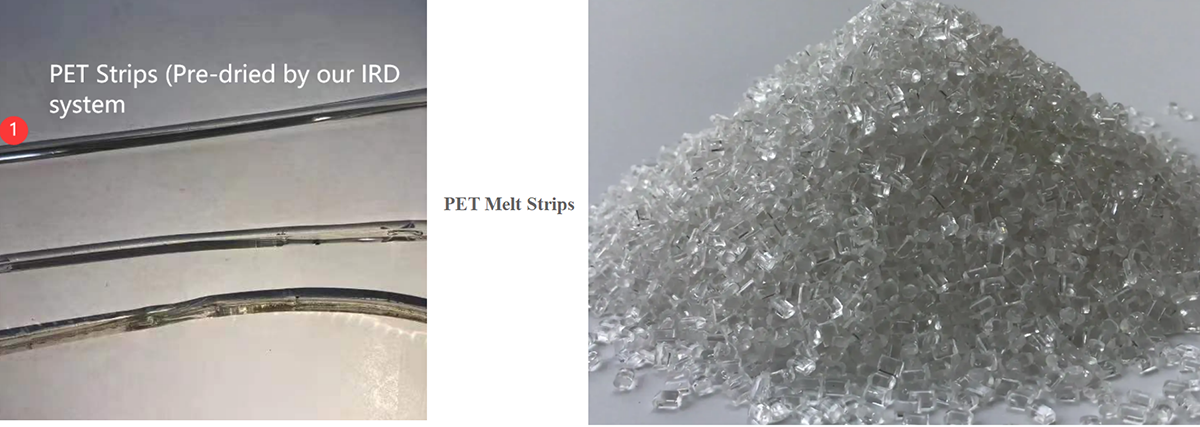

>> Sake sarrafa flakes a cikin extruder yana rage IV saboda hydrolysis i kasancewar ruwa,kuma shi ya sa kafin bushewa zuwa matakin bushewa iri ɗaya tare da Tsarin IRD ɗin mu na iya iyakance wannan raguwa. Bugu da kari, resin baya rawaya saboda lokacin bushewa ya ragu (Lokacin bushewa kawai yana buƙatar 15-20mins, danshi na ƙarshe zai iya zama≤ 50ppm, amfani da makamashi kasa da 80W/KG/H), da kuma shearing a cikin extruder shi ma an rage shi saboda preheated abu shiga extruder a akai-akai zazzabi”

>> A mataki na farko, PET regrind yana crystallized kuma ya bushe a cikin IRD a cikin kusan mintuna 15. Ana samun wannan tsari na crystallization da bushewa ta hanyar yin amfani da hasken infrared, don cimma yanayin zafin jiki na 170˚C. Ya bambanta da jinkirin tsarin iska mai zafi, shigarwar makamashi mai sauri da kai tsaye yana sauƙaƙe daidaitaccen daidaituwa na ƙimar danshi mai canzawa na dindindin - tsarin sarrafawa na radiation na IR yana ba da damar amsawa ga canje-canjen yanayi a cikin daƙiƙa. Ta wannan hanyar, ƙimar da ke tsakanin 5,000 da 8,000 ppm ana rage su daidai gwargwado a cikin IRD zuwa matakin danshi na kusan 30-50ppm.

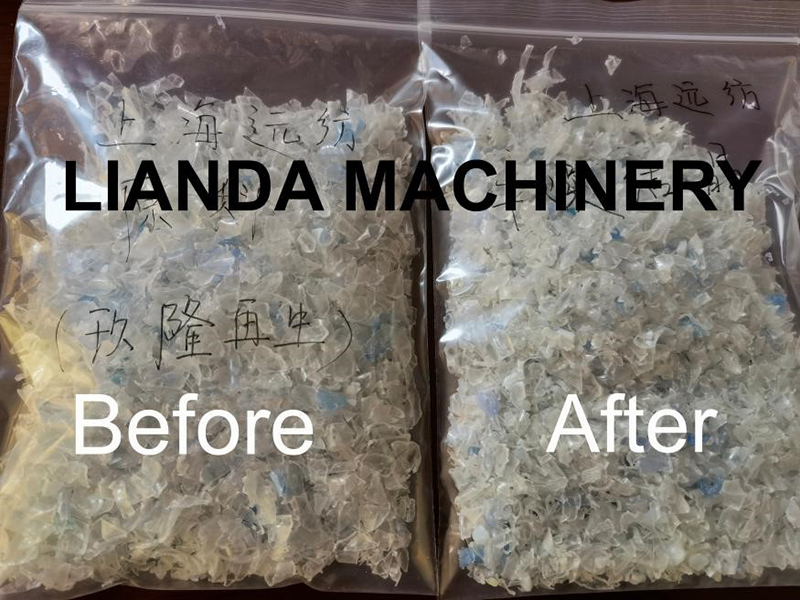

>>A matsayin sakamako na biyu na tsari na crystallization a cikin IRD, yawan adadin ƙasa yana ƙaruwa,musamman a cikin flakes masu nauyi sosai. Wannan sakamako na biyu yana da ban sha'awa sosai akan bangon cewa dabi'ar zuwa kwalabe masu sirara suna hana kayan sake yin amfani da su daga samun yawan yawa na> 0.3 kg/dm³. Ana iya samun haɓakar girma mai yawa ta 10 zuwa 20% a cikin IRD, wanda ya bayyana ba shi da mahimmanci a gani na farko, amma yana inganta aikin ciyarwa a mashigin extruder sosai - yayin da saurin fitar da sauri ya kasance baya canzawa, akwai ingantaccen aikin cikawa akan dunƙule.

Lokacin aikawa: Afrilu-07-2023