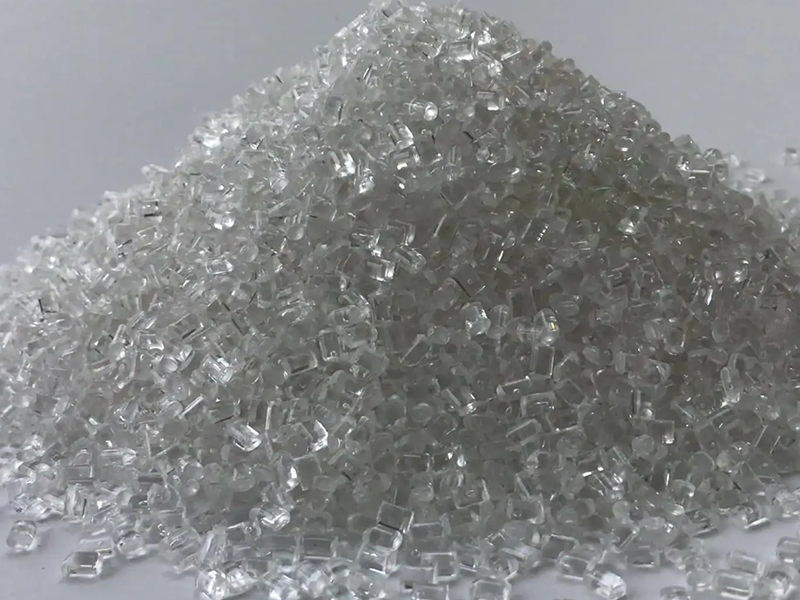

Infrared crystal bushewa PET Granulation

PET Bottle Flake Layin Granulation/Duƙun Ruwa Biyu Extruder│ R-PET

Infrared Pre-Bushewa na PET Flakes: Haɓaka Fitarwa da Inganta Inganci akan PET Extruders

>> Haɓaka masana'anta da kaddarorin jiki na sake yin fa'ida, matakin abinci na PET ta hanyar fasahar da ke da ƙarfi ta hasken infrared yana da muhimmin sashi don takawa a cikin kaddarorin danko (IV).

Pre-crystallization da bushewa na flakes kafin extrusion yana taimakawa rage asarar IV daga PET, muhimmin mahimmanci don sake amfani da resin.

Reprocessing da flakes a cikin extruder rage IV saboda hydrolysis i gaban ruwa, kuma shi ya sa pre-bushewa zuwa kama bushewa matakin da mu IRD System iya iyakance wannan rage. Bugu da kari, resin baya rawaya saboda lokacin bushewa ya ragu (Lokacin bushewa kawai yana buƙatar 15-20mins, danshi na ƙarshe zai iya zama≤ 50ppm, amfani da makamashi kasa da 80W/KG/H), da kuma shearing a cikin extruder shi ma an rage shi saboda preheated abu shiga extruder a akai-akai zazzabi”

>> Inganta fitar da PET Extruder

Ana iya samun haɓakar girma mai yawa ta 10 zuwa 20% a cikin IRD, yana haɓaka aikin ciyarwa a mashigar extruder sosai - yayin da saurin fitarwa ya kasance baya canzawa, akwai ingantaccen aikin cikawa akan dunƙule.

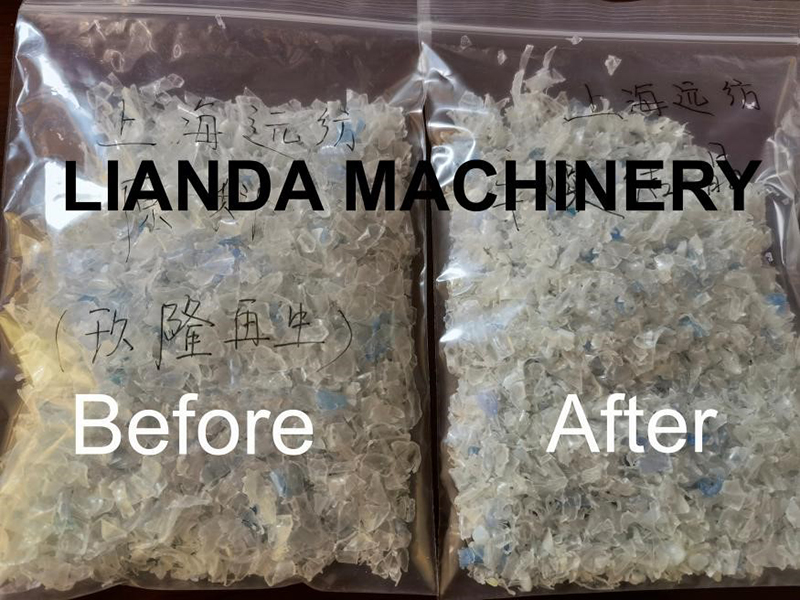

R-PET Flake Pelletizing/Layin Extrusion│R-PET

Sarrafa inji

→ Infrared crystal dryer → Screw feeder → tsarin ciyarwa → PET Biyu dunƙule Extruder → Vacuum degassing tsarin

Na'ura mai cire ruwa ←Flushing pelletizier←Tsarin ruwa ←Ruwan sanyaya ruwa ya mutu kai

Filastik da za a sake yin amfani da su sun haɗa da

* PET / BOPET kwalban kwalban, fim ɗin dabbobi, fiber na dabbobi, zanen sharar gida, fim ɗin gani

* Gidan kamun kifi na PA66, kafet

| Samfura | Diamita na dunƙule (mm) | L/D | Ƙarfin Mota (kw) | Iya aiki (kg/h) |

| Saukewa: GTE52B | 52 | 32-60 | 55 | 50-150 |

| Saukewa: GTE65B | 65 | 32-60 | 90 | 150-350 |

| Saukewa: GTE75B | 75 | 32-60 | 132 | 400-500 |

| Za mu iya samar muku da injin pelleting gwargwadon buƙatun ku. | ||||