bushewar gyada Kashe kwayoyin cuta

Misalin Aikace-aikace

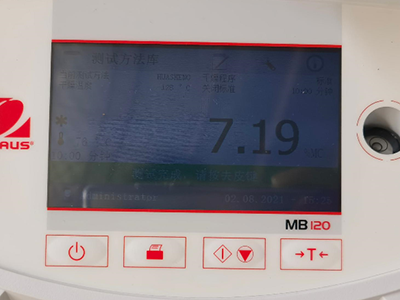

| Albarkatun kasa | Gyada Danshi na farko: 7.19% MC |   |

| Amfani da Machine | LDHW-600*1000 |  |

| Bushewa&Crystalized Saitin Zazzabi | 150 ℃ Za'a iya daidaita shi ta hanyar kayan albarkatun ƙasa | |

| saita lokacin bushewa | 40 min | |

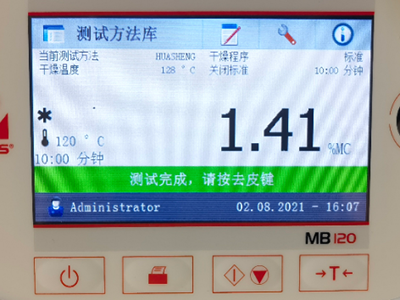

| Busasshen Gyada | Danshi na ƙarshe 1.41% MC |   |

Yadda Ake Aiki

Abin da za mu iya yi muku

√ Rage Kwayoyin cuta da Kariyar Hannu

An inganta shi don rage cutar ƙwayoyin cuta har zuwa> 5-1og (an ingantacce). Wannan yayi daidai da raguwar ƙwayoyin cuta ninki miliyoyi

√ Ragowar danshi da bushewa mai inganci

Za a iya bushe samfurin ƙarshe zuwa ƙasa da 1% a cikin mintuna maimakon sa'o'i

√ ingancin samfurin ƙarshe

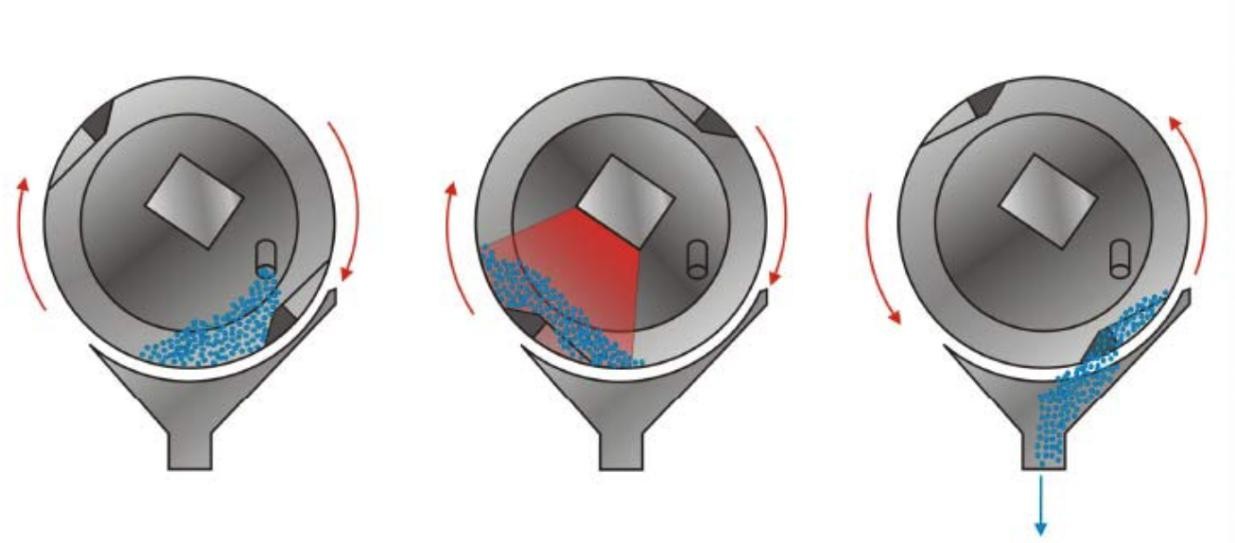

Ƙa'idar aiki mai juyawa ta amfani da hasken infrared yana inganta ingancin samfurin ƙarshe. Ga wasu samfurori, ana iya fitar da dandano yayin sarrafa bushewa

√ Digiri daban-daban na gasasshen

Matakan gasa iri-iri don haka dandano da bambancin launi, ana iya samun su ta hanyar saita yanayin zafi da lokacin zama. Ingantacciyar ɗanɗanon gasasshen.

√ Amfanin makamashi, haɓaka samarwa zuwa 50%

Ƙa'idar aiki ta baya na hasken infrared (makamashi yana shiga cikin ainihin samfurin) kuma yana ba da ingantaccen amfani da samfurin) yana ba da ingantaccen amfani da makamashi kuma yana ba da fa'idodi masu kyau akan sauran hanyoyin.

Hotunan Inji

Shigar da inji

>> Samar da ƙwararren injiniya zuwa masana'antar ku don taimakawa shigarwa da gwajin kayan aiki

>> Ɗauki filogi na jirgin sama, babu buƙatar haɗa wayar lantarki yayin da abokin ciniki ke samun injin a cikin masana'anta. Don sauƙaƙe matakin shigarwa

>> Samar da bidiyon aiki don shigarwa da jagorar gudu

>> Taimako akan sabis na layi

Yadda Ake Tabbatar da Ingancin!

>> Domin tabbatar da daidaiton kowane bangare, an sa mu da kayan aikin sarrafa ƙwararru iri-iri kuma mun tara hanyoyin sarrafa ƙwararru a cikin shekarun da suka gabata.

>> Kowane bangare kafin taro yana buƙatar kulawa sosai ta hanyar duba ma'aikata.

>>Kowace majalissar tana kula da wani ubangida ne wanda ya kware wajen aiki sama da shekaru 20

>> Bayan an kammala duk kayan aikin, za mu haɗa dukkan injunan kuma za mu gudanar da cikakken layin samarwa don tabbatar da ingantaccen aiki a masana'antar abokan ciniki.

Ayyukanmu

>> Za mu samar da gwaji idan abokin ciniki ya zo ziyarci masana'anta don ganin injin.

>> Za mu ba da cikakken bayani dalla-dalla na injin, zane na lantarki, shigarwa, littafin aiki da duk takaddun da abokin ciniki ke buƙata don share kwastan da amfani da injin.

>> Za mu samar da injiniyoyi don taimakawa shigarwa da horar da ma'aikata a wurin abokin ciniki.

>> Kayan kayan gyara suna samuwa lokacin da ake buƙata .A cikin lokacin garanti, za mu samar da kayan gyara kyauta, kuma a kan lokacin garanti, za mu samar da kayan aiki tare da farashin masana'anta.

>> Za mu samar da goyon bayan fasaha da kuma gyara sabis a cikin dukan rayuwa .