PET Flake/scrap dehumidifier crystallizer

Misalin Aikace-aikace

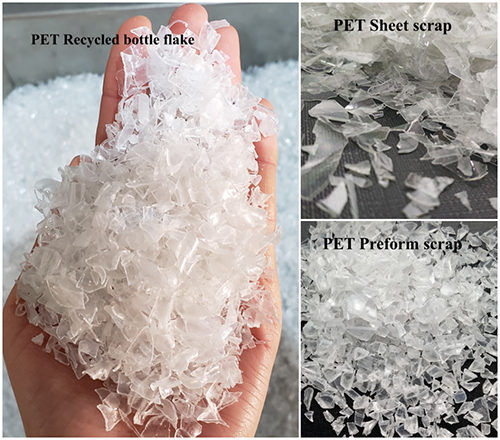

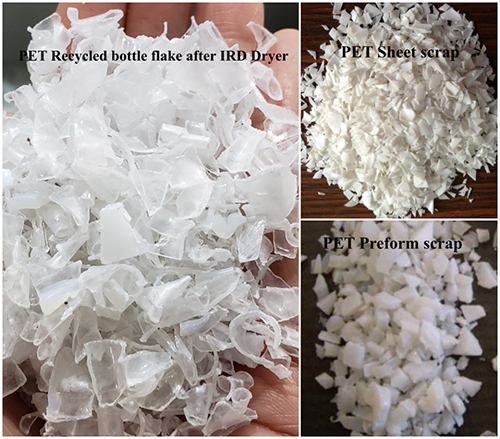

| Albarkatun kasa | PET Tushen da aka sake yin fa'ida / PET tarkace / PET Preform tarkace |

|

| Amfani da Machine | LDHW-600*1000 |  |

| Bushewa&Crystalized Saitin Zazzabi | 180-200 ℃ Za a iya daidaitacce ta dukiya na rawmaterial | |

| Saitin lokacin crystallized | 20 min | |

| Abu na ƙarshe | Crystallized da Busassun tarkacen PET dadanshi na ƙarshe zai iya zama kusan 30ppm |  |

Yadda Ake Aiki

Ciyarwa/Loading

Dry& Crystallization Processing

Ana fitarwa

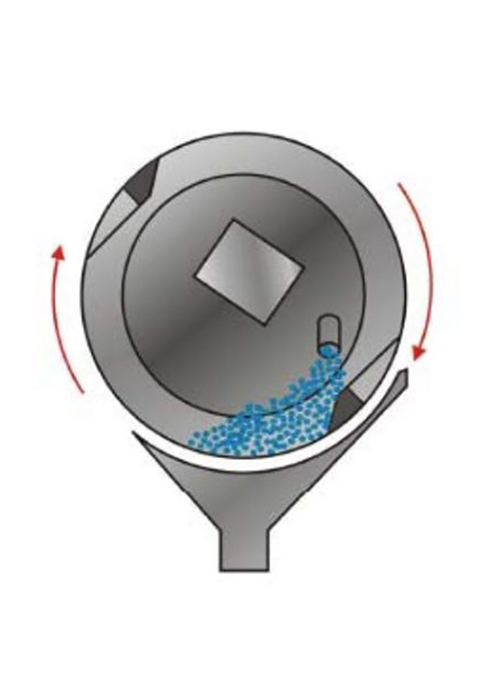

>>A mataki na farko, manufa ɗaya kawai shine don dumama kayan zuwa yanayin zafin da aka saita.

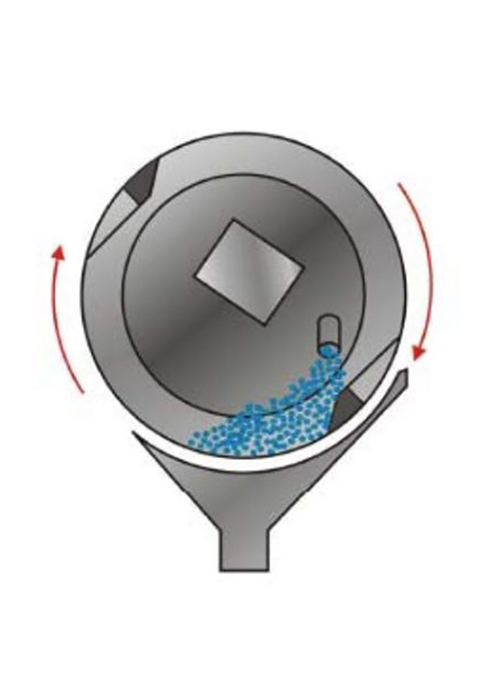

Ɗauki ɗan jinkirin saurin juyawa na ganga, ƙarfin fitilun Infrared na na'urar bushewa zai kasance a matakin mafi girma, sannan pellet ɗin PET za su sami saurin dumama har sai zafin jiki ya tashi zuwa zafin da aka saita.

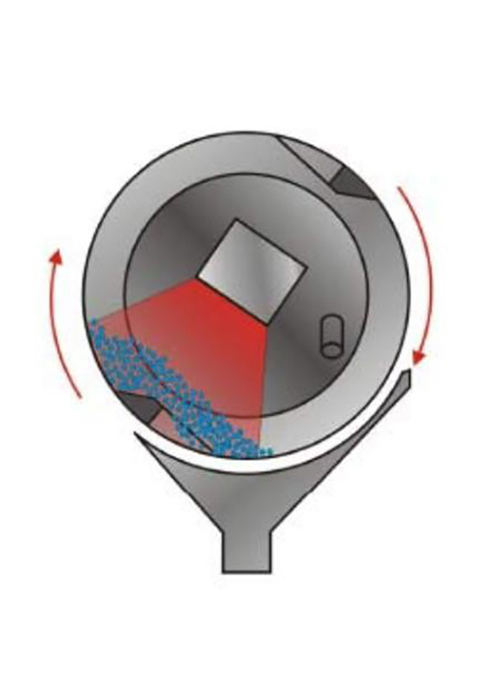

>>Bushewa &Crystalizing mataki

Da zarar kayan ya kai ga zafin jiki, za a ƙara saurin ganga zuwa saurin jujjuyawa mai yawa don guje wa ƙulle kayan. A lokaci guda, za a sake ƙara ƙarfin fitilun infrared don gama bushewa. Sannan saurin jujjuya ganga za a sake rage gudu. Yawanci aikin bushewa zai ƙare bayan 15-20mins. (Ainihin lokacin ya dogara da dukiyar kayan)

>>Bayan kammala aikin bushewa, Drum IR zai sauke kayan ta atomatik kuma ya sake cika ganga don sake zagayowar na gaba.

Cikewa ta atomatik da kuma duk sigogin da suka dace don madaidaitan zafin jiki daban-daban an haɗa su sosai a cikin sarrafa allon taɓawa na zamani. Da zarar an sami sigogi da bayanan zafin jiki don takamaiman abu, za'a iya adana saitunan abubuwan a matsayin girke-girke a cikin tsarin sarrafawa.

Amfaninmu

Yawanci kwalabe na PET ko tarkace tare da matakin danshi na farko har zuwa 10000-13000ppm. The PET kwalban flakes ko takarda scrap (Burji ko gauraye) za a recrystallized a cikin Infrared crystal bushewa a cikin 20mins, da bushewa zafin jiki zai zama 150-180 ℃ da kuma bushe zuwa 50-70ppm, sa'an nan kuma ciyar da Single dunƙule extruding tsarin don ƙarin aiki.

● Ƙayyadaddun lalacewa na hydrolytic na danko.

● Hana haɓaka matakan AA don kayan tare da hulɗar abinci

● Ƙara ƙarfin layin samarwa har zuwa 50%

● Haɓakawa da sanya ingancin samfurin ya tsayayye-- Daidaitaccen abun ciki mai shigar da ruwa mai maimaitawa na kayan

● Har zuwa 60% ƙasa da amfani da makamashi fiye da tsarin bushewa na al'ada

● Babu rarrabuwa na samfura tare da nau'ikan yawa daban-daban

● Zazzabi mai zaman kanta da saita lokacin bushewa

● Sauƙi mai tsabta da canza kayan

● Farawa nan take da saurin rufewa

● Kirkirar Uniform

● Babu ƙwalƙwalwa masu dunƙulewa & sanda

● Maganin kayan aiki a hankali

Teburin Kwatanta

| Abu | IRD Dryer | Na'urar bushewa ta al'ada |

| Canja wurin matsakaici | Babu | Iska mai zafi |

| Canja wurin zafi | Duka ciki & waje barbashi tare. | Daga waje zuwa ciki a hankali. |

| Makamashi | Ajiye aƙalla 20 ~ 50% kuzari idan aka kwatanta da na'urar bushewa na gargajiya. | Cin kuzari da yawa. |

| Lokacin aiwatarwa | 1. Crystallization & bushewa: Ana sarrafa su lokaci guda a cikin kusan mintuna 8 ~ 15. 2. bushewa da crystallization a lokaci guda | 1. Crystallization: Game da 30 ~ 60 mintuna. 2. bushewa: Game da 4 ~ 6 hours. |

| Danshi abun ciki | 1. Karkashin 50-70 PPM bayan sarrafa IRD. | 1. Ku ciyar da mintuna 30 ~ 60 don canza PET amorphous zuwa PET crystallized farko. 2. Ƙarƙashin 200PPM bayan kimanin sa'o'i 4 na cire humidifier. 3. Ƙarƙashin 50 PPM bayan kusan fiye da sa'o'i 6 na cire humidifier. |

| Lokacin jagora | 20 min | Fiye da awanni 6. |

| Canjin kayan abu | 1. Sauƙi & sauri. 2. Akwai kawai 1 ~ 1.5 sau iya aiki na kayan amfani da sa'a guda a cikin buffer hopper. | 1. Wahala & sannu a hankali. 2. Akwai 5 ~ 7 sau damar yin amfani da kayan aiki na sa'o'i a cikin crystallizer & hopper. |

| Aiki | Sauƙaƙe --- Ta Siemens PLC iko

| Yana da wahala kamar dole ne ya sanya PET ɗan ƙarami a cikin crystallizer lokacin fara aiki. |

| Kulawa | 1. Sauƙi. 2. Ƙananan farashin kulawa. | 1. Wahala. 2. Mafi girman farashin kulawa. |

Hotunan Inji

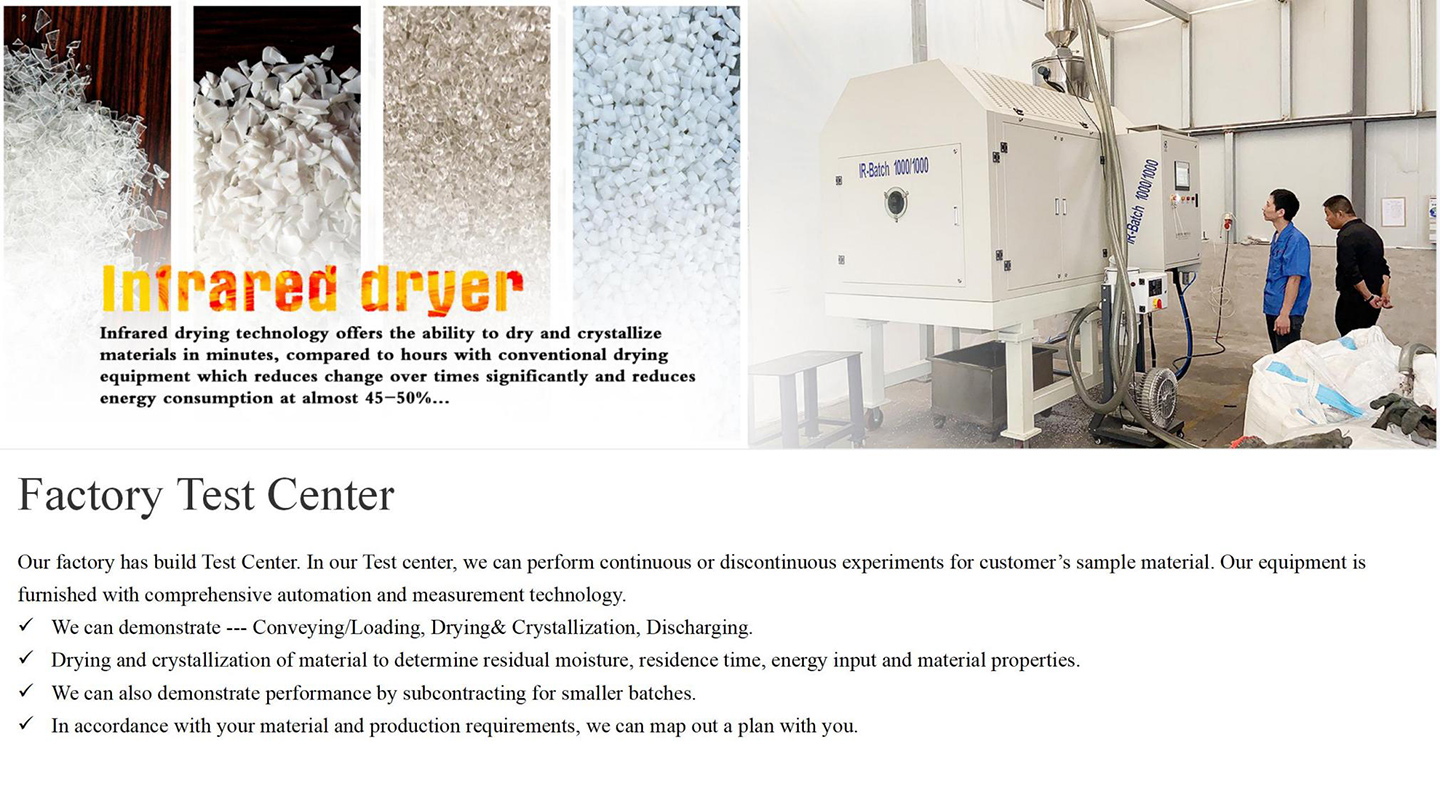

Gwajin Kyauta na Kayan abu

Kwararren injiniya ne zai yi gwajin. Ana gayyatar ma'aikatan ku da gaisuwa don shiga cikin hanyoyin haɗin gwiwa. Don haka kuna da duka yuwuwar ba da gudummawa sosai da kuma damar ganin samfuranmu suna aiki.

Shigar da inji

>> Samar da ƙwararren injiniya zuwa masana'antar ku don taimakawa shigarwa da gwajin kayan aiki

>> Ɗauki filogi na jirgin sama, babu buƙatar haɗa wayar lantarki yayin da abokin ciniki ke samun injin a cikin masana'anta. Don sauƙaƙe matakin shigarwa

>> Samar da bidiyon aiki don shigarwa da jagorar gudu

>> Taimako akan sabis na layi