Filastik guduro bushewa

Misalin Aikace-aikace

| Albarkatun kasa | PET Resin CR-BrightNa kunshin abinci |  |

| Amfani da Machine | LDHW-600*1000 |  |

| Danshi na farko | 2210pmJarrabawar da Jamusanci Sartorius Moisture gwajin kayan aikin |  |

| Saitin zafin jiki na bushewa | 200 ℃ | |

| saita lokacin bushewa | 20 min | |

| Danshi na karshe | 20ppm kuJarrabawar da Jamusanci Sartorius Moisture gwajin kayan aikin |  |

| Samfurin ƙarshe | Busasshen guduro na PET ba mai dunƙulewa ba, babu ƙwanƙwasa manne |  |

Yadda Ake Aiki

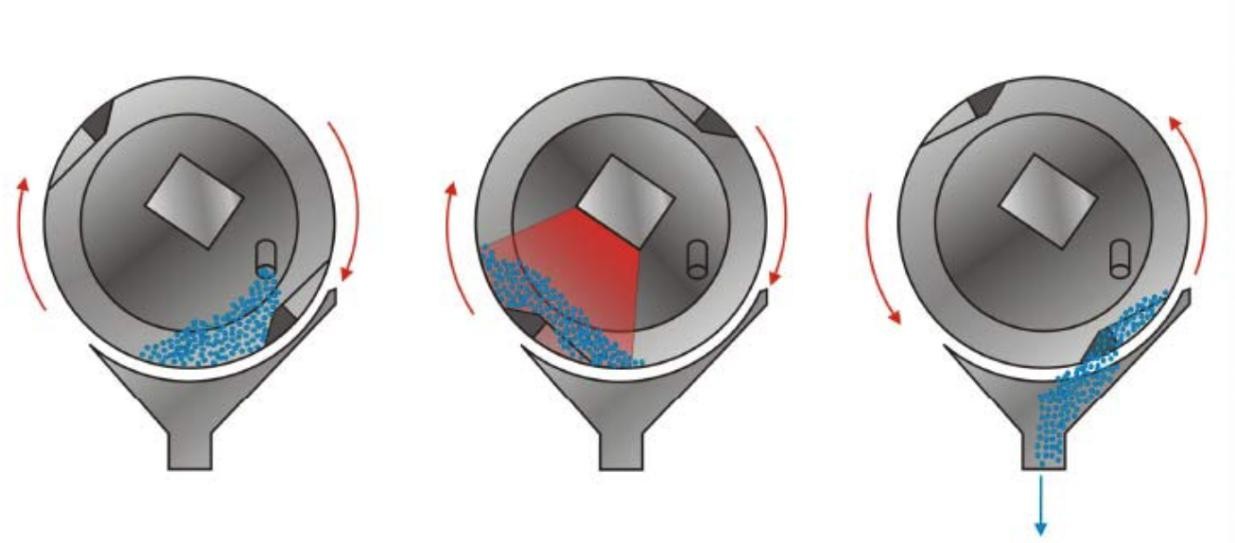

>>A mataki na farko, manufa ɗaya kawai shine don dumama kayan zuwa yanayin zafin da aka saita.

Ɗauki ɗan jinkirin saurin juyawa na ganga, ƙarfin fitilun Infrared na na'urar bushewa zai kasance a matakin mafi girma, sannan pellet ɗin PET za su sami saurin dumama har sai zafin jiki ya tashi zuwa zafin da aka saita.

>> Matakin bushewa

Da zarar kayan ya kai ga zafin jiki, za a ƙara saurin ganga zuwa saurin jujjuyawa mai yawa don guje wa ƙulle kayan. A lokaci guda, za a sake ƙara ƙarfin fitilun infrared don gama bushewa. Sannan saurin jujjuya ganga za a sake rage gudu. Yawanci aikin bushewa zai ƙare bayan 15-20mins. (Ainihin lokacin ya dogara da dukiyar kayan)

>>Bayan kammala aikin bushewa, Drum IR zai sauke kayan ta atomatik kuma ya sake cika ganga don sake zagayowar na gaba.

Cikewa ta atomatik da kuma duk sigogin da suka dace don madaidaitan zafin jiki daban-daban an haɗa su sosai a cikin sarrafa allon taɓawa na zamani. Da zarar an sami sigogi da bayanan zafin jiki don takamaiman abu, za'a iya adana saitunan abubuwan a matsayin girke-girke a cikin tsarin sarrafawa.

Amfaninmu

| 1 | Ƙananan amfani da makamashi | Mahimmanci ƙananan amfani da makamashi idan aka kwatanta da matakai na al'ada, ta hanyar gabatarwa kai tsaye na infrared makamashi zuwa samfurin | |

| 2 | Mintuna maimakon sa'o'i | Samfurin ya kasance na 'yan mintuna kaɗan kawai a cikin tsarin bushewa sannan yana samuwa don ƙarin matakan samarwa. | |

| 3 | Nan take | Ayyukan samarwa na iya farawa nan da nan bayan farawa. Ba a buƙatar lokacin dumi na injin. | |

| 4 | A hankali | Ana yin zafi da kayan a hankali daga ciki zuwa waje kuma ba a ɗora shi daga waje ba har tsawon sa'o'i tare da zafi, kuma ta haka zai iya lalacewa. | |

| 5 | A mataki daya | Crystallization da bushewa a mataki daya | |

| 6 | Ƙara kayan aiki | Ƙara yawan kayan aikin shuka ta hanyar rage nauyi akan extruder | |

| 7 | Babu dunƙulewa, babu tsayawa | Juyawa na ganga yana tabbatar da motsi na kayan aiki akai-akai.Kwayoyin karkace da abubuwa masu haɗaka da aka tsara don samfurin ku suna tabbatar da haɗin kayan aiki mafi kyau kuma yana guje wa haɗuwa. Samfurin yana da zafi sosai | |

| 8 | Siemens PLC girma | Sarrafa.Bayanan tsari, kamar kayan abu da shayewar zafin iska ko matakan cika ana ci gaba da lura da su ta hanyar na'urori masu auna firikwensin da pyrometers. Rarraba yana haifar da daidaitawa ta atomatik.Reproducibility.Recipes da sigogi na tsari za'a iya adana su a cikin tsarin sarrafawa don tabbatar da sakamako mafi kyau da sake sakewa. Kulawa da nesa. Sabis na kan layi ta hanyar modem. | |

| 9 | Lokacin bushewa kawai yana buƙatar 20mins, danshi na ƙarshe zai iya zama ≤ 30ppm | Hasken infrared wanda ke shiga da kuma yin tunani daga kayan ba zai shafi tsarin kayan aiki ba, amma nama mai shayarwa za a canza shi zuwa makamashi mai zafi saboda tashin hankali na kwayoyin halitta, wanda ke haifar da zafin jiki na kayan ya tashi. | |

| 10 | Babu dunƙulewa, babu tsayawa | Juyawa na ganga yana tabbatar da motsi na kayan aiki akai-akai.Kwayoyin karkace da abubuwa masu haɗaka da aka tsara don samfurin ku suna tabbatar da haɗin kayan aiki mafi kyau kuma yana guje wa haɗuwa. Samfurin yana da zafi sosai | |

| 11 | Sauƙi mai tsabta da canza abu | Kyakkyawan damar yin amfani da duk abubuwan da aka gyara yana ba da damar sauƙi da tsaftacewa da sauri. Canjin samfurin da sauri. | |

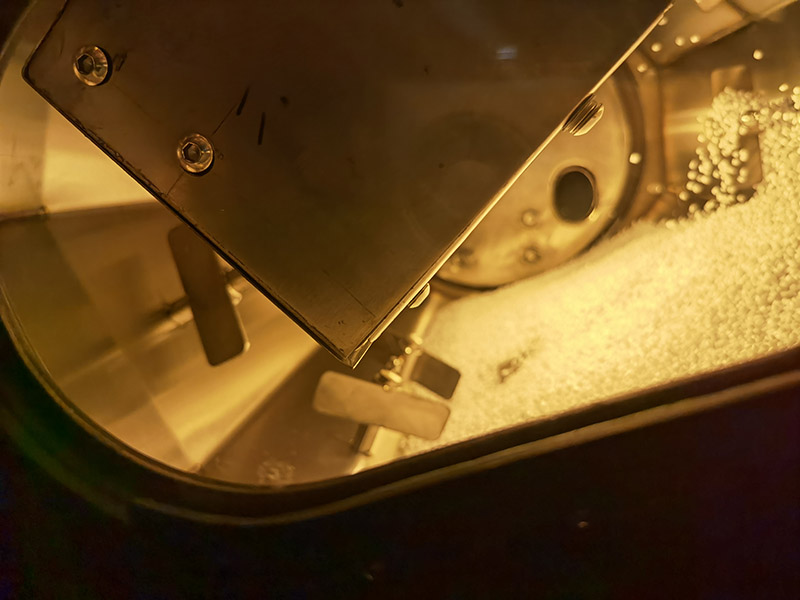

Hotunan Inji

Aikace-aikacen Inji

Bushewa bushewa na filastik granulates (PET, TPE, PETG, APET, RPET, PBT, ABS / PC, HDPE, LCP, PC, PP, PVB, WPC, TPU da dai sauransu) kazalika da sauran free- gudana girma kayan.

Crystallization PET (Kwalban flakesm granulates, takarda takarda), PET Masterbatch, CO-PET, PBT, PEEK, PLA, PPS da dai sauransu

Daban-daban Thermal da aka sarrafa don cire sauran oligomeren da abubuwan da ba su da ƙarfi

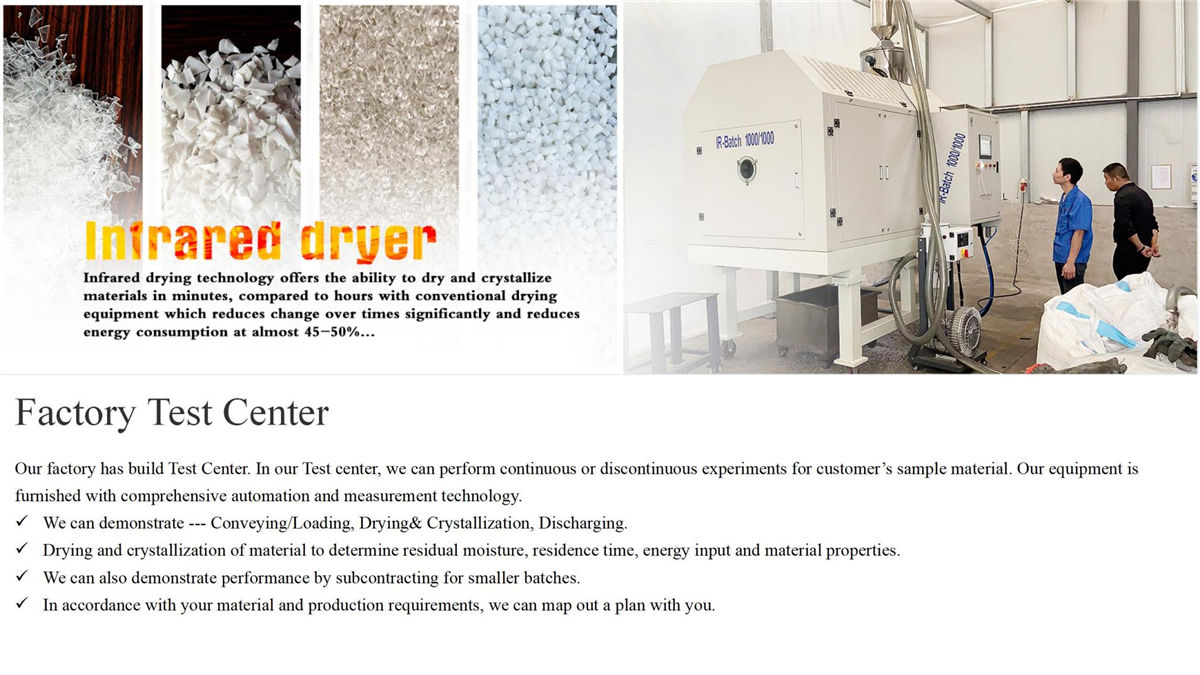

Gwajin Kyauta na Kayan abu

Kwararren injiniya ne zai yi gwajin. Ana gayyatar ma'aikatan ku da gaisuwa don shiga cikin hanyoyin haɗin gwiwa. Don haka kuna da duka yuwuwar ba da gudummawa sosai da kuma damar ganin samfuranmu suna aiki.

Shigar da inji

>> Samar da ƙwararren injiniya zuwa masana'antar ku don taimakawa shigarwa da gwajin kayan aiki

>> Ɗauki filogi na jirgin sama, babu buƙatar haɗa wayar lantarki yayin da abokin ciniki ke samun injin a cikin masana'anta. Don sauƙaƙe matakin shigarwa

>> Samar da bidiyon aiki don shigarwa da jagorar gudu

>> Taimako akan sabis na layi