PLA PET thermoforming Sheet extrusion line

Infrared crystal dryer+ PET Sheet Extrusion line

Ribar da muke yi

>>LIANDA ci gaba daSingle dunƙule extrusion line tare da Infrared crystal bushewadon takardar PET, 20mins pre-bushewa da crystallization, danshi na ƙarshe zai iya zama ≤50ppm (Layin Injin Aiki mai ƙarfi, kwanciyar hankali na ƙarshe)

Layin extrusion yana da kaddarorin ƙarancin amfani da makamashi, tsarin samar da sauƙi da sauƙin kulawa.

Tsarin dunƙule ɓarna na iya rage asarar danko na guduro PET, mirgina mai siffa da bakin ciki na calender yana inganta tasirin sanyaya, iya aiki da ingancin takarda.

Multi-bangaren dosing feeder yana sarrafa kashi na sabon abu, sake amfani da kayan aiki da babban tsari daidai,.

An yi amfani da takardar ko'ina don masana'antar marufi na thermoforming.

>>Infrared crystal dryer ------Bushe &Crystallize R-PET flakes/chips a cikin 20mins a 30ppm ta hanyar adana 45-50% farashin makamashi.

※Ƙayyadaddun lalacewar hydrolytic na danko.

※ Hana haɓaka matakan AA don kayan tare da hulɗar abinci

※ Ƙara ƙarfin layin samarwa har zuwa 50%

※ Haɓakawa da sanya ingancin samfurin ya tsaya tsayin daka-- Daidaitacce kuma mai maimaita abun cikin shigar da danshi na kayan

Rage farashin kera takardar PET: Har zuwa 60% ƙarancin amfani da makamashi fiye da tsarin bushewa na al'ada

Farawa kai tsaye da sauri rufe --- Babu buƙatar pre-dumama

Za a sarrafa bushewa& crystallization a mataki ɗaya

Don haɓaka ƙarfin tensile na takardar PET, Ƙara ƙarin ƙimar--- Danshi na ƙarshe zai iya zama ≤30ppm da 20minsBusassun &Crystalization

- Layin injin yana sanye da tsarin Siemens PLC tare da aikin ƙwaƙwalwar maɓalli ɗaya

- Yana rufe yanki na ƙananan tsari mai sauƙi da sauƙi don aiki da kulawa

- Zazzabi mai zaman kanta da saita lokacin bushewa

- Babu rarrabuwa na samfuran tare da nau'ikan girma daban-daban

- Sauƙi mai tsabta da canza abu

>> PET Extrusion inji line

| Samfura | Multi Layer | Layer guda ɗaya | Ingantaccen inganci |

| Bayanin Extruder | LD75&36/40-1000 | LD75/40-1000 | LD95&62/44-1500 |

| Kauri daga cikin samfurin | 0.15-1.5 mm | 0.15-1.5 mm | 0.15-1.5 mm |

| Babban wutar lantarki | 110kw/45kw | 110 kw | 250kw/55kw |

| Max iyawar extrusion | 500kg/h | 450kg/h | 800-1000kg/h |

Jerin inji

| Haɗin Na'ura | ||

| NO | Inji | Yawan |

| 1 | PET Infrared crystal bushewa | 1 saiti |

| 2 | Vacuum dunƙule feeder | 1 saiti |

| 3 | Biyu dunƙule extruder | 1 saiti |

| 4 | Vacuum korau tsarin matsa lamba | 1 saiti |

| 5 | Tace tasha biyu | 1 saiti |

| 6 | Narkar da famfo mai aunawa | 1 saiti |

| 7 | PET musamman mold mutu | 1 saiti |

| 8 | Kalandar jujjuya uku-uku kafa sashi | 1 saiti |

| 9 | Silicone mai shafi da na'urar tanda | 1 saiti |

| 10 | Edge abu yankan na'urar | 1 saiti |

| 11 | Na'urar dawo da kayan Edge | 1 saiti |

| 12 | Tsarin iska biyu tasha | 1 saiti |

| 13 | SIEMENS tsarin kula da mu'amala da injin mutum | 1 saiti |

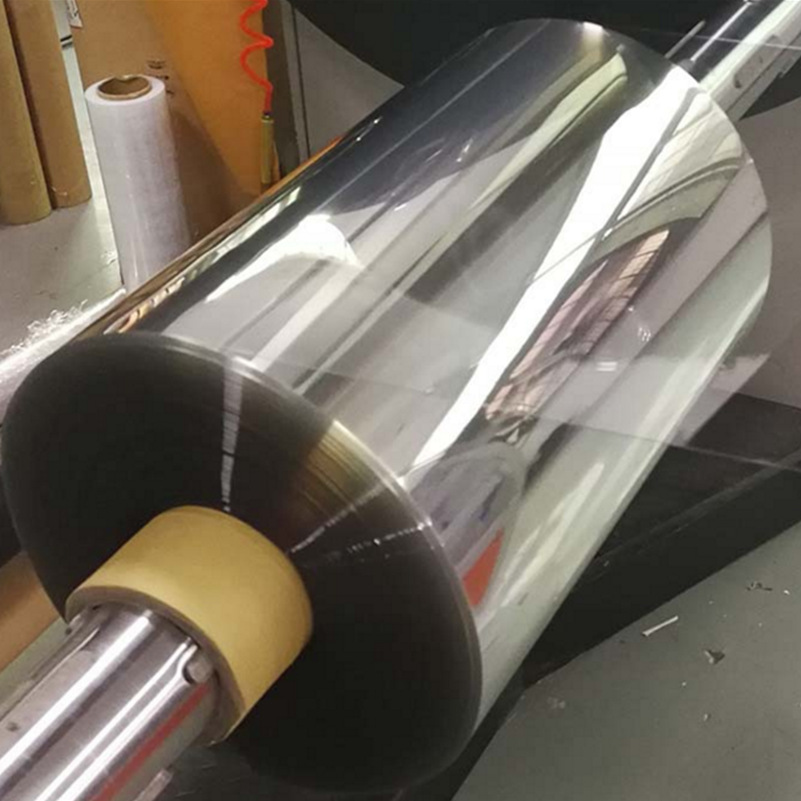

Hotunan Inji

FAQ

Tambaya: Menene danshi na ƙarshe da za ku iya samu? Shin kuna da iyakancewa kan danshin farko na albarkatun ƙasa?

A: Danshi na ƙarshe za mu iya samun ≤30ppm (Ɗauki PET a matsayin misali). Danshi na farko zai iya zama 6000-15000ppm.

Q: Muna amfani da sau biyu a layi daya dunƙule extruding tare da injin degassing tsarin for PET Sheet extrusion, za mu har yanzu bukatar yin amfani da pre-bushe?

A: Muna ba da shawarar amfani da Pre-bushe kafin extrusion. Yawancin lokaci irin wannan tsarin yana da ƙayyadaddun buƙatu akan farkon danshi na kayan PET. Kamar yadda muka sani PET wani nau'in abu ne wanda zai iya ɗaukar danshi daga yanayi wanda zai sa layin extrusion yayi aiki mara kyau. Don haka muna ba da shawarar amfani da pre-bushe kafin tsarin extrusion ku:

>> Ƙayyadaddun lalacewa na hydrolytic na danko

>>Hana haɓaka matakan AA don kayan tare da hulɗar abinci

>>Ƙara ƙarfin layin samarwa har zuwa 50%

>> Ingantawa da sanya ingancin samfurin ya tsaya tsayin daka-- Daidaitacce kuma mai maimaita abun ciki na kayan shigar da shi

Tambaya: Za mu yi amfani da sabon abu amma ba mu da wani kwarewa don bushewa irin wannan abu. Za ku iya taimaka mana?

A: Kamfaninmu yana da Cibiyar Gwaji. A cikin cibiyar gwajin mu, za mu iya yin gwaje-gwajen ci gaba ko dakatarwa don samfurin samfurin abokin ciniki. An samar da kayan aikin mu tare da ingantattun fasahar sarrafa kansa da fasahar aunawa.

Za mu iya nuna --- Bayarwa/Loading, bushewa & Crystallization, Fitarwa.

Bushewa da crystallization na abu don ƙayyade saura danshi, lokacin zama, shigar da makamashi da kayan abu.

Hakanan za mu iya nuna aiki ta hanyar kwangilar ƙasa don ƙananan batches.

Dangane da kayan aikin ku da buƙatun samarwa, zamu iya tsara tsari tare da ku.

Kwararren injiniya ne zai yi gwajin. Ana gayyatar ma'aikatan ku da gaisuwa don shiga cikin hanyoyin haɗin gwiwa. Don haka kuna da duka yuwuwar ba da gudummawa sosai da kuma damar ganin samfuranmu suna aiki.

Tambaya: Menene lokacin bayarwa na IRD ɗin ku?

A: Kwanaki 40 na aiki tun lokacin da muka sami kuɗin ku a asusun kamfanin mu.

Tambaya: Yaya game da shigar da IRD ɗin ku?

Kwarewar injiniya na iya taimaka maka shigar da tsarin IRD a masana'anta. Ko kuma za mu iya ba da sabis na jagora akan layi. Duk injin ɗin yana ɗaukar filogin jirgin sama, mai sauƙin haɗi.

Tambaya: Menene IRD za a iya nema?

A: Yana iya zama pre-bushe don

PET/PLA/TPE Sheet extrusion inji line

PET Bale madaurin yin inji line

PET masterbatch crystallization da bushewa

PETG Sheet extrusion line

PET monofilament inji, PET monofilament extrusion line, PET monofilament ga tsintsiya.

Injin yin fim na PLA/PET

PBT, ABS / PC, HDPE, LCP, PC, PP, PVB, WPC, TPE, TPU, PET (Bottleflakes, granules, flakes), PET masterbatch, CO-PET, PBT, PEEK, PLA, PBAT, PPS da dai sauransu.

Hanyoyin thermal donkau da sauran oligomeren da maras tabbas sassa.