rPET pallets Crystallization Dryer

PET Infrared crystallization Dryer don R-PET Pellets ---- OD Technology Made

>> Dry &Crystalize PET Chips/Flake/Pellets a cikin 20mins a 30ppm ta hanyar adana 45-50% farashin makamashi.

- Har zuwa 60% ƙasa da amfani da makamashi fiye da tsarin bushewa na al'ada

- crystallization Uniform

- Babu pellets masu dunƙule & sanda

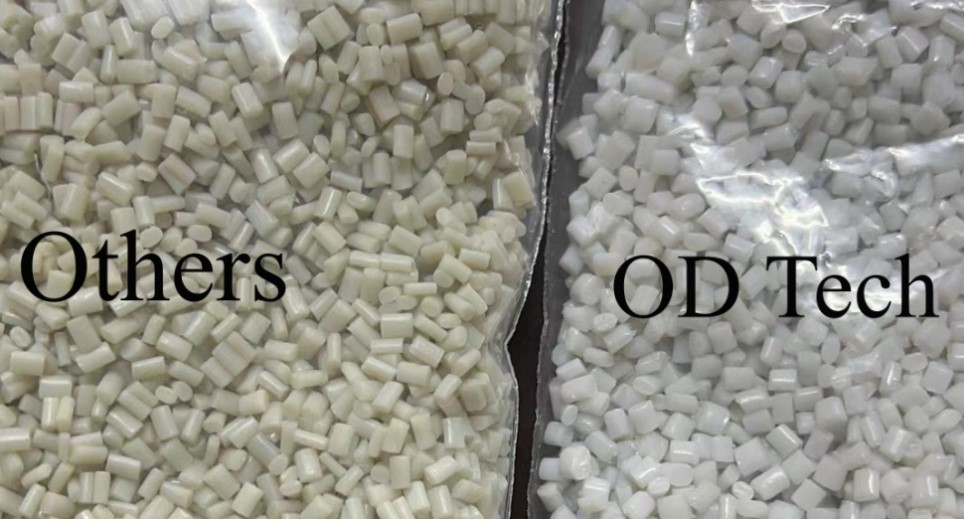

- Launin Crystallization Milk fari

- A hankali magani kayan aiki

- Nan take farawa da sauri rufewa

- Zazzabi mai zaman kanta da saita lokacin bushewa

- Babu rarrabuwa na samfuran tare da nau'ikan girma daban-daban

- Sauƙi mai tsabta da canza abu

Yadda za a Haɓaka ƙarin ƙimar samfurin R-PET Pellets/PET Pellets da kwalbar kwalba ta yi taInfrared crystallization Dryer?

| 1 | Uniform crystallization, high a crystallization rate Launi na crystallization: fari mai tsabta

|

Farashin sayarwa zai kasance USD30-50 kowace ton

|

| 2 | Crystallization da bushe za a gama a mataki daya Danshi na ƙarshe zai iya zama ≤50ppm | Zai zama kyakkyawan ma'ana ga mai amfani na gaba, kamar masana'antar PET Preform, PET Sheet ƙera ko masana'anta Fiber da sauransu. Zai rage lokacin bushewa. |

| 3 | Cikakken inji mai sarrafa ta Siemens PLC Touch allon tare da aikin ƙwaƙwalwar ajiya, farawa maɓalli ɗaya. | Don rage dabarar farashin aiki. |

| 4 | Ajiye kusan 45-50% farashin makamashi idan aka kwatanta da na'urar bushewa | Dauki 500kg/h Infrared crystal bushewa model a matsayin misali, da lantarki kudin ne kasa da 100W/KG/HR |

Abin da za mu iya yi muku

>> Ƙayyadad da lalacewar hydrolysis na danko.

>> Hana haɓaka matakan AA don kayan tare da hulɗar abinci

>>Ƙara ƙarfin layin samarwa har zuwa 50%

>> Ingantawa da sanya ingancin samfurin ya tsaya tsayin daka-- Daidaitaccen abun shigar da mai maimaituwa

>>Akwai yankuna masu kula da zafin jiki na PID guda uku, kuma ana iya saita zafin bushewar crystal bisa ga halayen albarkatun ƙasa.

>> Rotary aiki style iya zama aiki a matsayin mahautsini. Kuna iya ciyar da kashi na PET Chips da pellets da aka sake yin fa'ida zuwa na'urar bushewar Infrared crystal ɗinmu kai tsaye, zai haɗa kayan ta atomatik.

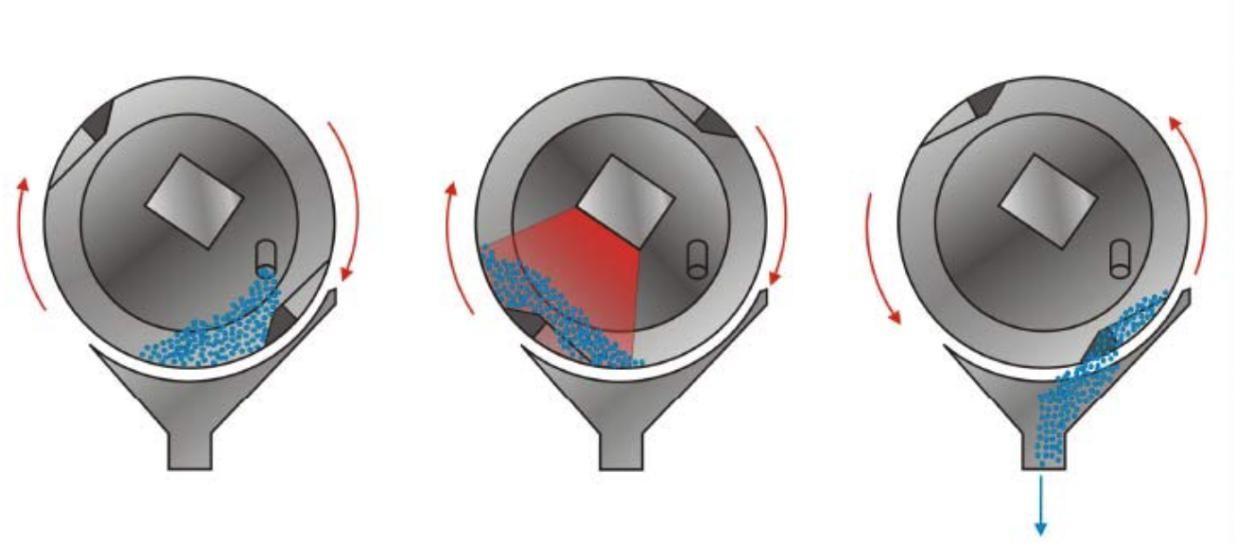

Yadda ake aiki

Ciyarwa/Loading

Dry& Crystallization Processing

Ana fitarwa

>>A mataki na farko, manufa ɗaya kawai shine don dumama kayan zuwa yanayin zafin da aka saita.

Ɗauki ɗan jinkirin saurin juyawa na ganga, ƙarfin fitilun Infrared na na'urar bushewa zai kasance a matakin mafi girma, sannan pellet ɗin PET zai sami saurin dumama har sai zafin jiki ya tashi zuwa zafin da aka saita.

>>Bushewa &Crystalizing mataki

Da zarar kayan ya kai ga zafin jiki, za a ƙara saurin ganga zuwa saurin jujjuyawa mai yawa don guje wa ƙulle kayan. A lokaci guda, za a sake ƙara ƙarfin fitilun infrared don gama bushewa. Sannan saurin jujjuya ganga za a sake rage gudu. Yawanci aikin bushewa zai ƙare bayan 15-20mins. (Ainihin lokacin ya dogara da dukiyar kayan)

>>Bayan kammala aikin bushewa, Drum IR zai sauke kayan ta atomatik kuma ya sake cika ganga don sake zagayowar na gaba.

Cikewa ta atomatik da kuma duk sigogin da suka dace don madaidaitan zafin jiki daban-daban an haɗa su sosai a cikin sarrafa allon taɓawa na zamani. Da zarar an sami sigogi da bayanan zafin jiki don takamaiman abu, za'a iya adana saitunan abubuwan a matsayin girke-girke a cikin tsarin sarrafawa.

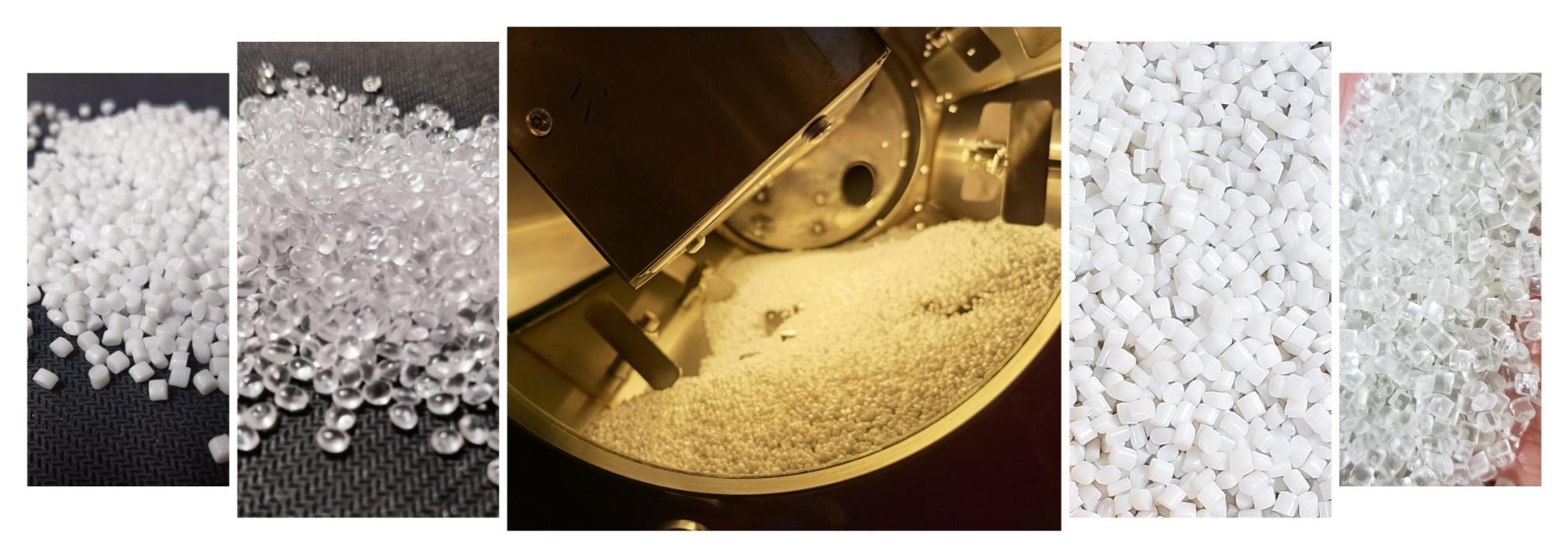

Hotunan inji don tunani

Gwajin kyauta na kayan abu

Kwararren injiniya ne zai yi gwajin. Ana gayyatar ma'aikatan ku da gaisuwa don shiga cikin hanyoyin haɗin gwiwa. Don haka kuna da duka yuwuwar ba da gudummawa sosai da kuma damar ganin samfuranmu suna aiki.

>> Samar da ƙwararren injiniya zuwa masana'antar ku don taimakawa shigarwa da gwajin kayan aiki

>> Ɗauki filogi na jirgin sama, babu buƙatar haɗa wayar lantarki yayin da abokin ciniki ke samun injin a cikin masana'anta. Don sauƙaƙe matakin shigarwa

>> Samar da bidiyon aiki don shigarwa da jagorar gudu

>> Taimako akan sabis na layi