High Quality for Plastic Can Crusher - Plastic Lump Crusher/ Lump block shredder/Hard plastic Crusher/Waste grinding machine – LIANDA

High Quality for Plastic Can Crusher - Plastic Lump Crusher/ Lump block shredder/Hard plastic Crusher/Waste grinding machine – LIANDA Detail:

Hard plastic Crusher — LIANDA Design

>> Lianda granulators can be applied for a variety of plastics into valuable granules. It is ideal from processing blow-molded materials like PET bottles, PE/PP bottles, containers, or buckets. With this machine, it’s possible to shred even the toughest of materials.

Machine Details Shown

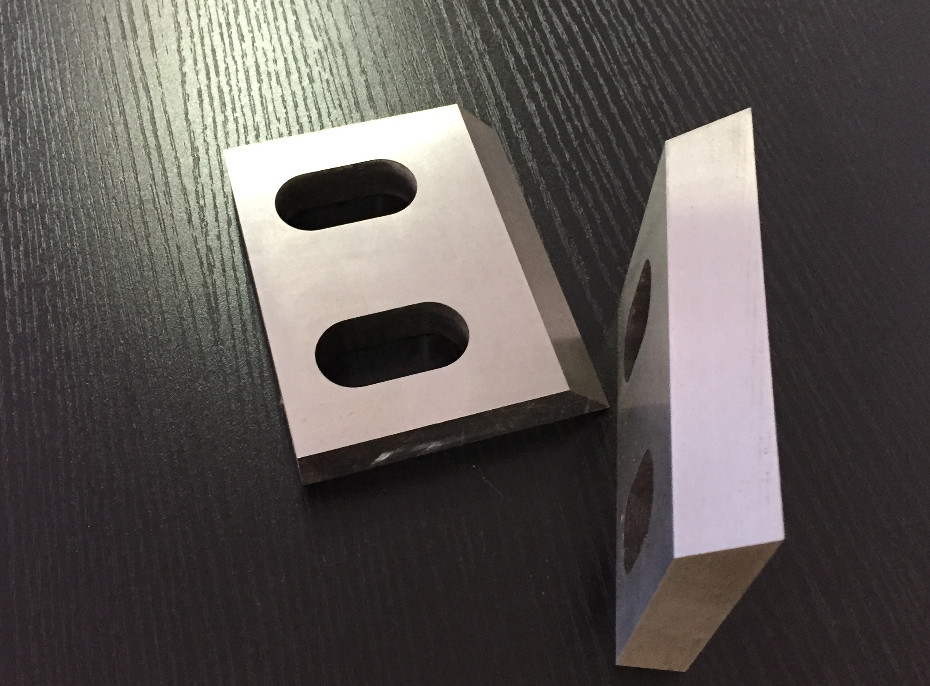

Blade Frame Design

>>Blades are made of high-strength alloy tool steel, with high hardness, good abrasion resistance, and long durability.

>>Adopted hexagon socket screw installation way of the blades and strong wear resistance.

>>Material: CR12MOV, hardness in 57-59°

>>All spindles have passed strict dynamic and static balance tests to ensure the reliability of machine operation.

>>The spindle design can be customized according to different material requirements.

Charming Room

>>The design of the plastic bottle crusher is reasonable, and the body is welded with high-performance steel;

>>Adopt high-strength screws to fasten, solid structure and durable.

>>Chamber wall thickness 50mm, more stable in crushing process due to better load-bearing, hence with higher durability.

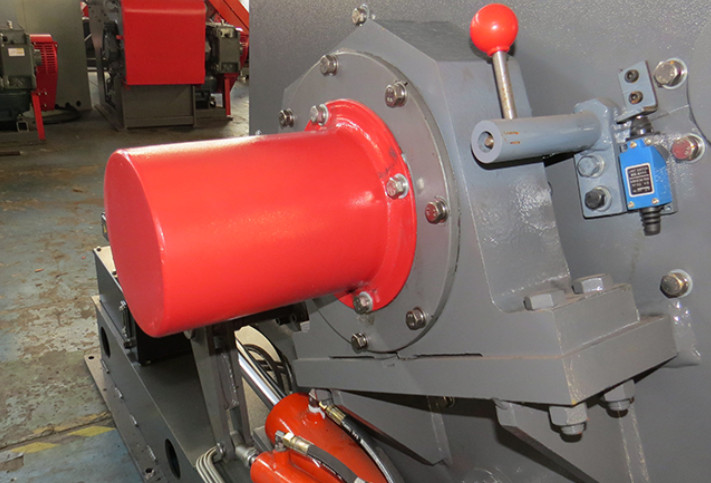

External bearing seat

>> The main shaft and the machine body are sealed by sealing ring, effectively avoid the casing of the crushing of material into the bearing, improve the bearing life

>> Suitable for wet and dry crushing.

Crusher open

>>Adopt Hydraulic open.

Hydraulic tipping device can efficiently, safely and quickly improve the blade sharpening work;

>>Convenient for machine maintenance and the replacement of blades

>>Optional:the screen bracket are hydraulically controlled

Crusher Blades

>> Blades material can be 9CrSi, SKD-11, D2 or customized

>>Special blade making processing to improve the blades working time

Sieve Screen

>>The crushed flake/scrap size are uniform and the loss is small. Multiple screens can be replaced at the same time to meet different needs

Machine Technical Parameter

|

Model

|

UNIT |

300 |

400 |

500 |

600 |

|

Rotary blades |

pcs |

9 |

12 |

15 |

18 |

|

Stable blades |

pcs |

2 |

2 |

2 |

4 |

|

Motor Power |

kw |

5.5 |

7.5 |

11 |

15 |

|

Grinding Chamber |

mm |

310*200 |

410*240 |

510*300 |

610*330 |

|

Capacity |

Kg/h |

200 |

250-300 |

350-400 |

450-500 |

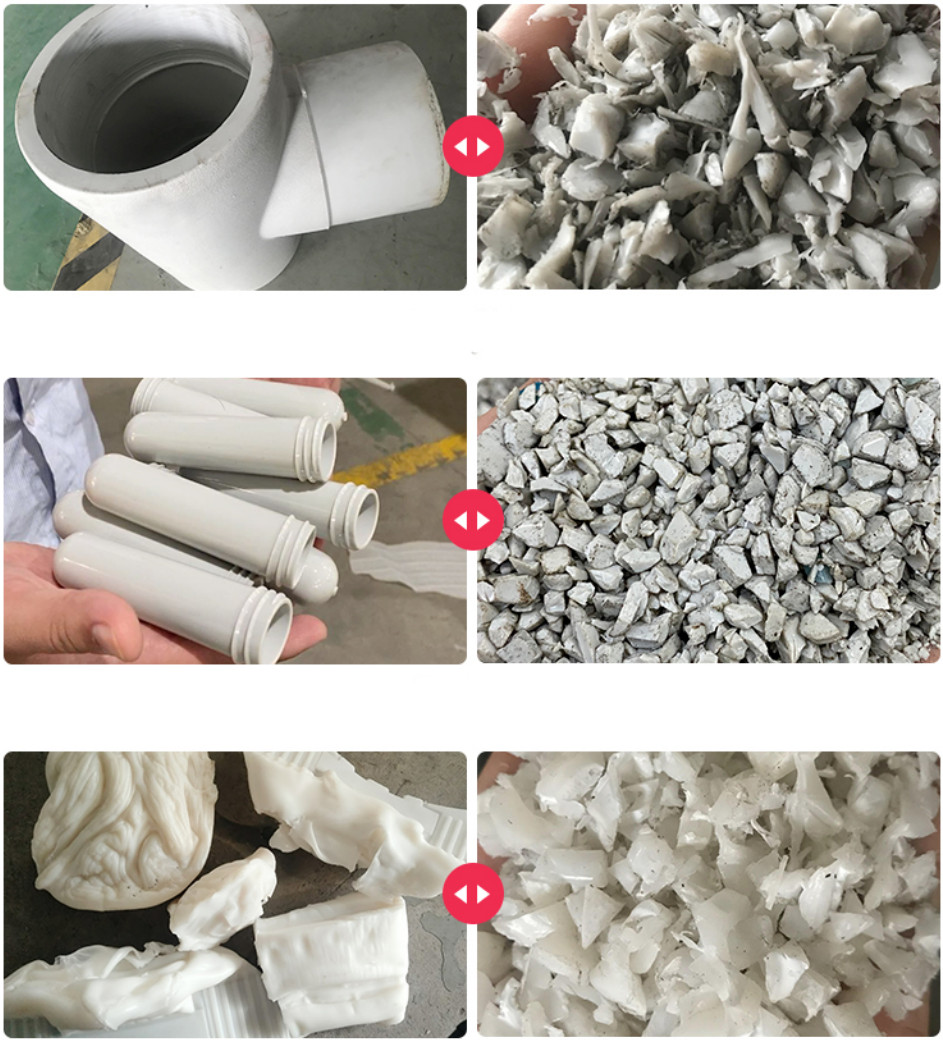

Application Samples shown

It can crush various soft and hard plastics and rubbers, such as: Purging, PVC Pipe, Rubbers, Preform, Shoe Last, Acrylic, Bucket, Rod, Leather, Plastic Shell, Cable Sheath, Sheets and so on.

Machine Installation

MACHINE FEATURES>>

>>Anti-wear machine housing

>>Claw type rotor configuration for films

>>Suitable for wet and dry granulation .

>>20-40% additional throughput

>>Heavy duty bearings

>>Oversized external bearing housings

>>Knives are externally adjustable

>>Robust welded steel construction

>>Wide choice of rotor variations

>>Electrical hydraulic control to open housing

>>Electrical hydraulic control to open screen cradle

>>Replaceable wear plates

>>Amp meter control

OPTIONS>>

>> Extra flywheel

>> Double infeed hopper roller feeder

>> Blade material 9CrSi, SKD-11, D2 or customized

>> Mounted screw feeder in hopper

>> Metal detector

>> Increased motor driven

>>Hydraulic controlled sieve screen

Machine Photos

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of High Quality for Plastic Can Crusher - Plastic Lump Crusher/ Lump block shredder/Hard plastic Crusher/Waste grinding machine – LIANDA, The product will supply to all over the world, such as: Georgia, Jordan, kazan, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The products to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!