Tsis siv neeg riam sib tsoo tshuab

Riam sharpener yog tsim rau cov hniav xws li crusher hniav, ntawv txiav hniav, woodworking planer hniav, yas tshuab hniav, tshuaj cutters thiab lwm yam hniav.

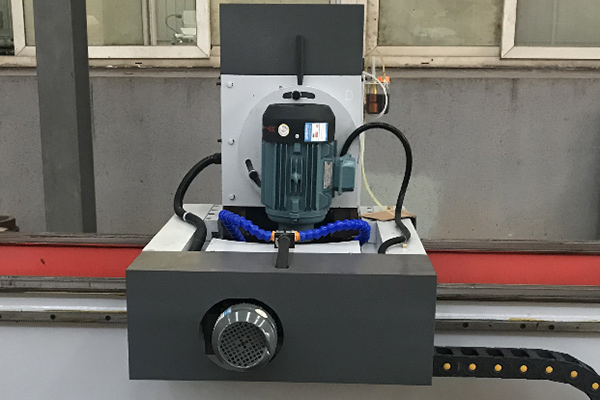

Muaj nrog kev sib tsoo ntev li ntawm 1500 hli txog 3100 hli, lossis ntev dua rau kev sib tsoo tshwj xeeb. Hniav sib tsoo tshuab nta lub tshuab hnyav-lub luag haujlwm txhawb nqa lub hauv paus uas muab qhov siab tshaj plaws stability. PLC tswj cov tsheb thauj mus los thaum lub sijhawm ntau lub sijhawm ua haujlwm.

Peb Qhov Zoo

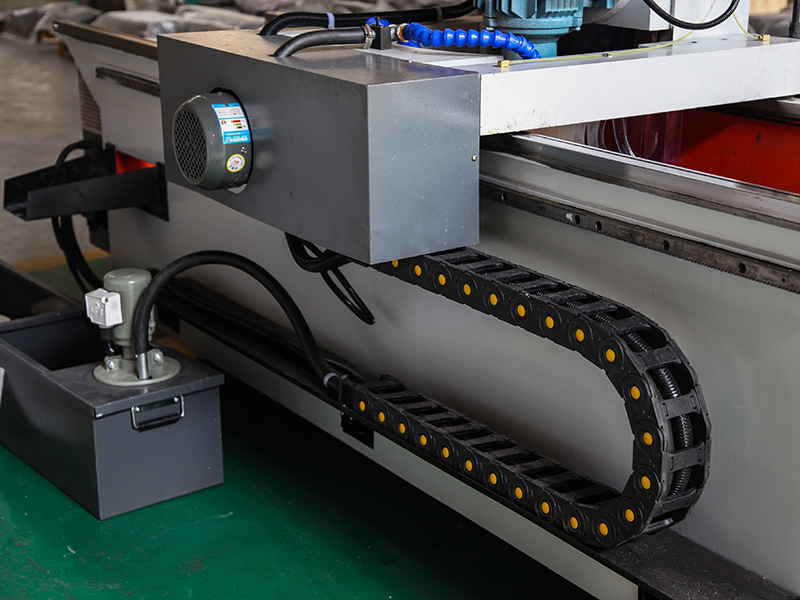

■ Precision qhia kev tsheb nqaj hlau, qhov saum npoo yog inlaid nrog cov khoom siv hlau zoo tiv thaiv, thiab txoj siv hlau yog yooj yim los hloov, kev sib kis tau ruaj khov thiab txhim khu kev qha, thiab kev pabcuam lub neej ntev.

■ Kev hloov pauv zaus pub, tus nqi pub thiab pub zaus yog tswj los ntawm kev hloov pauv zaus tshwj xeeb; npaum, raug thiab yooj yim.

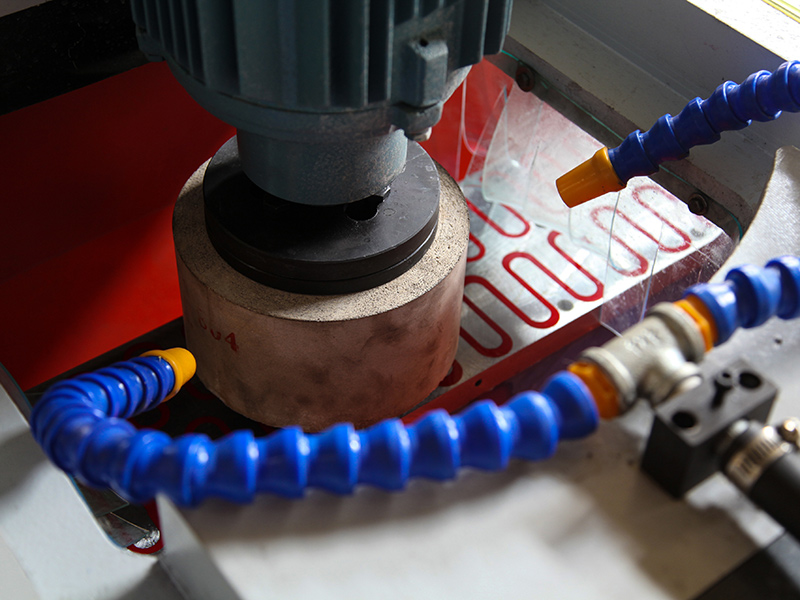

■ Copper coil haib electromagnetic suction khob, super suction, ruaj khov zoo; lub khob nqus dej rotates kom raug, nrog tsis siv neeg locking muaj nuj nqi, thiab ntau hom hniav workbench yuav customized.

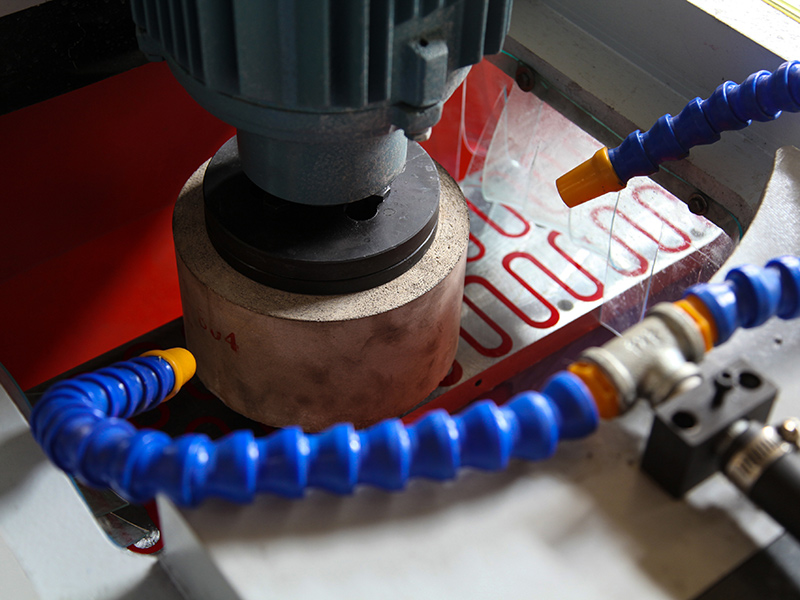

■ Lub tshuab tshwj xeeb sib tsoo lub taub hau tuaj yeem kho qhov axial clearance, muaj kev sib tsoo siab, tuaj yeem txhawb kev sib tsoo loj, thiab muaj kev pabcuam ruaj khov.

■ Lub txaj gantry-hom txaj ntawm lub tshuab ntse tsis siv neeg yog welded nrog cov hlau zoo zoo, thiab tau ua tiav kev laus thiab kev ua haujlwm zoo, nrog kev ceev ceev zoo.

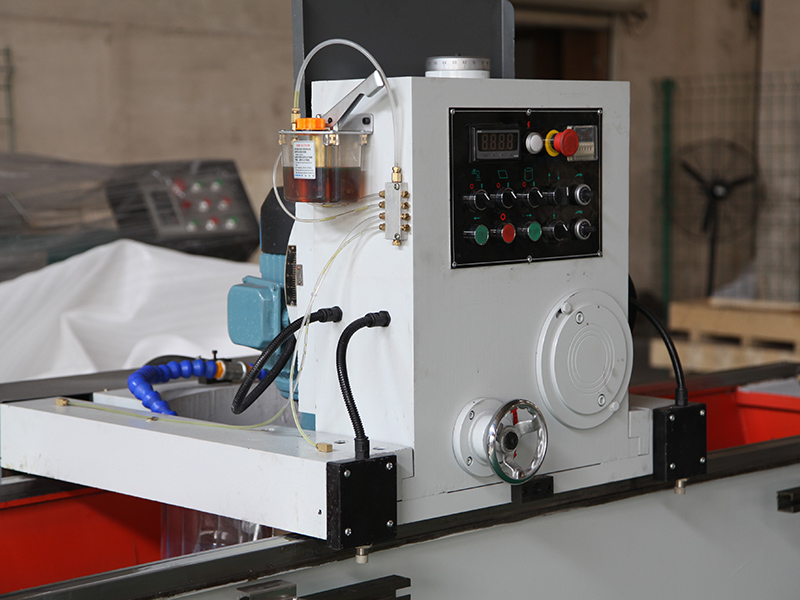

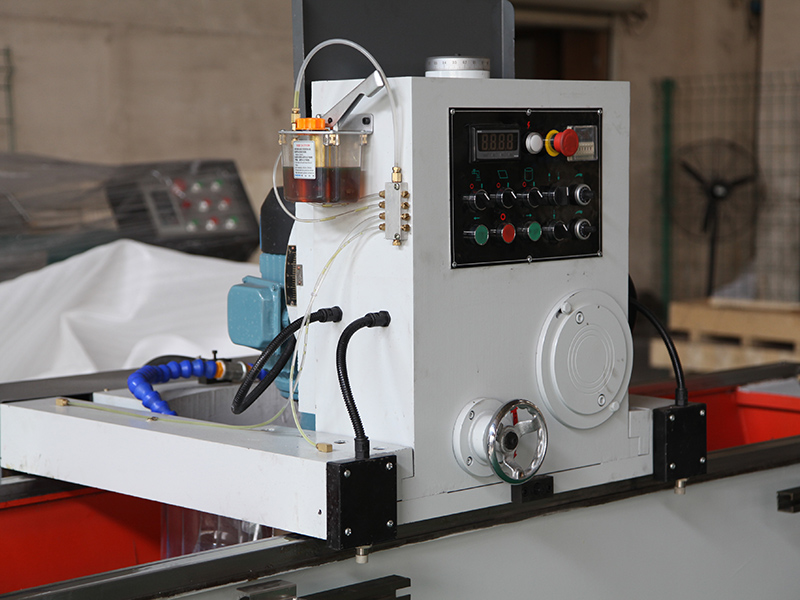

■ Centralized refueling device, ib zaug refueling, txuag lub sij hawm thiab yooj yim.

Yeem qhov chaw: ① polishing sab sib tsoo lub taub hau, ② zoo sib tsoo auxiliary sib tsoo taub hau, ③ theem nrab ntug sib tsoo taub hau.

Tshuab Paub meej Qhia

>> Lub lag luam interface yog qhov yooj yim thiab meej, rab riam tau txiav tawm, thiab kev noj ntau zaus tuaj yeem hloov kho;

>> Tsis siv neeg thiab phau ntawv ua haujlwm tuaj yeem hloov pauv dawb

>> Tshwj xeeb sib tsoo lub taub hau lub cev muaj zog, zoo precision, siab stability, nrog ceev sib tsoo log ntaus ntawv, yooj yim loading thiab unloading

>> Muaj zog tooj liab coil electromagnetic chuck, tshwj xeeb cov cuab yeej teeb tsa

>> qhov nqus chuck tig kom raug, nrog kev kaw haujlwm tsis siv neeg, thiab ntau yam ntawm cov hniav ua haujlwm tuaj yeem hloov kho.

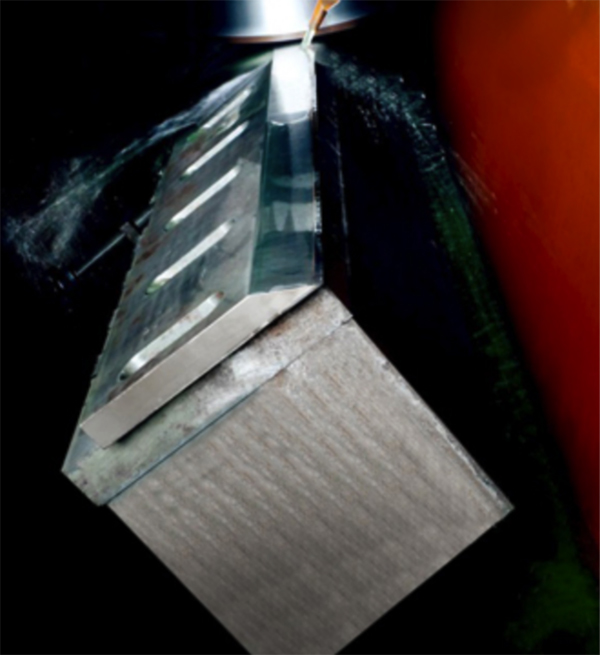

> > Blades sample

Ua tiav cov haujlwm ua tau raws li ntau tus neeg siv khoom xav tau

Tshuab Technical Paramate

| Hniav Grinder

| ||

| Cov hniav sib tsoo | Ntev | 1500-8000mm |

| Dav | ≤250mm | |

| Electromagnetic worktable | Dav | 180mm-220mm |

| Lub kaum sab xis | ± 90 ° | |

| Sib tsoo lub taub hau lub cev muaj zog | Hwj chim | 4/5.5kw |

| Rotating ceev | 1400 rpm ib | |

| Sib tsoo log | Txoj kab uas hla | Φ200mm * 110mm * Φ100 |

| Sib tsoo taub hau ncej | Mob stroke | 1-20m / min |

| Tag nrho qhov ntev | Ntev | 3000 hli |

| Dav | 1100 hli | |

| Qhov siab | 14 30mm | |

Tshuab duab

YUAV UA LI CAS YUAV UA LI CAS!

■ Yuav kom ntseeg tau qhov tseeb ntawm txhua qhov, peb tau nruab nrog ntau yam khoom siv ua haujlwm thiab peb tau sau cov txheej txheem kev ua haujlwm ntau xyoo dhau los.

■ Txhua yam khoom ua ntej sib dhos xav tau kev tswj xyuas nruj heev los ntawm kev tshuaj xyuas cov neeg ua haujlwm.

■ Txhua lub rooj sib txoos raug them los ntawm tus tswv uas muaj kev paub ua haujlwm ntau tshaj 20 xyoo

■ Tom qab tag nrho cov cuab yeej ua tiav, peb yuav txuas tag nrho cov cav tov thiab khiav tag nrho cov kab ntau lawm kom ntseeg tau tias kev khiav haujlwm ruaj khov