PET daim ntawv yog cov khoom siv yas uas muaj ntau yam kev siv hauv ntim, khoom noj, kev kho mob, thiab kev lag luam. PET daim ntawv muaj cov khoom zoo xws li pob tshab, lub zog, nruj, thaiv, thiab rov ua dua tshiab. Txawm li cas los xij, daim ntawv PET tseem yuav tsum tau ua kom qhuav thiab crystallization ua ntej extrusion, kom ntseeg tau tias nws zoo thiab kev ua tau zoo. Cov tshuab ziab khaub ncaws thiab crystallization feem ntau yog siv sij hawm, siv zog, thiab muaj teeb meem txog kev ya raws.

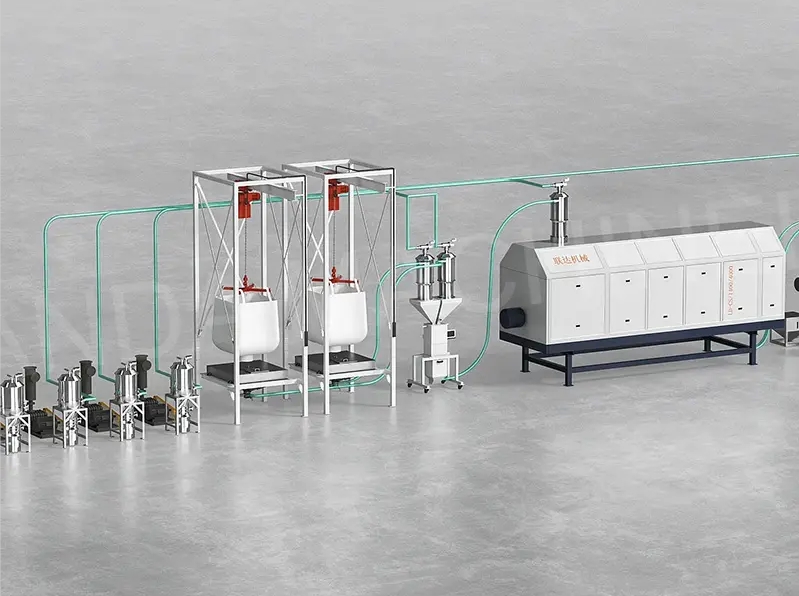

Kom kov yeej cov teeb meem no,LANDA MACHINERY, lub tuam txhab tshwj xeeb hauv cov khoom siv yas rov ua dua tshiab thiab ua cov khoom siv, tau tsim cov tshuaj tshiab rau ziab thiab crystallization ntawm PET regrind flake thiab nkauj xwb cob, hu ua IRD Dryer. Lub tshuab ziab khaub ncaws IRD yog lub tshuab siv hluav taws xob infrared thiab kev sib hloov ziab kom ua tiav sai, ua haujlwm tau zoo, thiab ua kom qhuav thiab crystallization ntawm PET cov khoom hauv ib kauj ruam. Lub tshuab ziab khaub ncaws IRD muaj ntau yam zoo dua li cov qauv siv, xws li:

• Tsis muaj kev sib cais ntawm cov khoom uas muaj ntau qhov sib txawv

• Kev pib sai sai thiab kaw sai dua

• Tsawg zog noj thiab cov khoom zoo

• Daim ntawv thov dav thiab ua haujlwm yooj yim

• PLC tswj thiab kov npo interface

Nyob rau hauv tsab xov xwm no, peb yuav piav qhia txog cov ncauj lus kom ntxaws cov khoom thiab kev ua tau zoo ntawm lubIRD Dryer rau PET daim ntawv ntau lawm kab, thiab nws tuaj yeem txhim kho qhov ua tau zoo, zoo, thiab muaj txiaj ntsig ntawm PET daim ntawv ua.

IRD Tshuab ziab khaub ncaws ua haujlwm li cas

Lub tshuab ziab khaub ncaws IRD yog lub tshuab uas muaj lub nruas teb, lub tshuab radiator, lub tshuab pub mis, lub tshuab tso tawm, thiab kev tswj xyuas. IRD Dryer ua haujlwm raws li hauv qab no:

• Cov khoom siv PET, xws li regrind flake lossis virgin resin, yog pub rau hauv lub nruas teb los ntawm lub tshuab pub mis, uas tuaj yeem yog lub ntim ntim ntim lossis cov khoom siv zaj duab xis yob, nyob ntawm seb hom khoom siv.

• Lub nruas teb yog nruab nrog kauv coils thiab cov khoom sib xyaw, uas ua kom muaj kev sib xyaw zoo thiab txav ntawm cov khoom hauv lub nruas. Lub nruas teb tuaj yeem kho nws qhov nrawm thiab kev taw qhia raws li cov txheej txheem thiab cov khoom siv.

• Lub radiator module nyob rau saum lub nruas teb, thiab nws emits luv-yoj infrared tawg, uas nkag mus rau hauv lub hauv paus ntawm cov khoom thiab heats nws sai heev. Lub radiator module yog txias los ntawm huab cua tsis tu ncua, thiab tiv thaiv los ntawm huab cua tiv thaiv, uas tiv thaiv cov plua plav tawm los ntawm kev nkag mus thiab ya raws los ntawm kev khiav tawm.

• Cov hluav taws xob infrared ua rau cov khoom kom qhuav thiab crystallization ib txhij, raws li cov cua kub ntws thawb cov dej noo los ntawm sab hauv mus rau sab nraud ntawm cov khoom, thiab cov qauv molecular ntawm cov khoom hloov ntawm amorphous mus rau crystalline. Cov dej noo yog muab tshem tawm los ntawm huab cua ncig hauv lub tshuab.

• Cov txheej txheem ziab thiab crystallization yuav siv li 15 mus rau 20 feeb, nyob ntawm seb cov khoom siv thiab qhov xav tau qhov kawg ntawm cov dej noo. Lub tshuab ziab khaub ncaws IRD tuaj yeem ua tiav qhov kawg ntawm cov dej noo tsawg dua 50 ppm, uas yog tsim rau PET daim ntawv extrusion.

• Tom qab cov txheej txheem ziab thiab crystallization tiav lawm, lub nruas teb cia li tso tawm cov khoom thiab rov ua dua lub nruas rau lub voj voog tom ntej. Cov khoom tso tawm tuaj yeem yog cov ntsia hlau conveyor lossis lub tshuab nqus tsev, nyob ntawm cov khoom siv thiab cov khoom siv hauv qab.

• Lub tshuab ziab khaub ncaws IRD yog tswj los ntawm lub xeev-of-the-art PLC system, uas saib xyuas thiab tswj cov txheej txheem tsis xws li cov khoom siv thiab cov pa cua kub, qib sau, lub sijhawm khaws cia, lub zog hluav taws xob, thiab lub nruas nrawm. Lub kaw lus PLC tseem muaj lub vijtsam kov, uas tso cai rau tus neeg teb xov tooj teeb tsa thiab txuag cov txheej txheem tsis ua haujlwm thiab ntsuas kub rau cov ntaub ntawv sib txawv raws li cov zaub mov txawv, thiab nkag mus rau kev pabcuam online ntawm modem.

Lub tshuab ziab khaub ncaws IRD yog lub tshuab yooj yim thiab siv tau zoo uas tuaj yeem ziab thiab crystallize PET cov ntaub ntawv hauv ib kauj ruam, siv hluav taws xob infrared thiab kev sib hloov ziab.

Qhov zoo ntawm IRD Tshuab ziab khaub ncaws

Lub tshuab ziab khaub ncaws IRD muaj ntau yam zoo dua li cov tshuab ziab khaub ncaws thiab crystallization, xws li:

• Tsis muaj kev sib cais ntawm cov khoom nrog ntau qhov sib txawv: Lub tshuab ziab khaub ncaws ua kom muaj kev txav mus tas li thiab sib xyaw ntawm cov khoom, tsis hais nws qhov loj, zoo li cas, lossis qhov ntom ntom. Qhov no tiv thaiv cov khoom los ntawm kev sib cais los yog clumping thaum lub sij hawm ziab thiab crystallization txheej txheem, thiab ua kom cov khoom zoo ib yam thiab zoo ib yam.

• Kev pib sai sai thiab kaw nrawm dua: IRD Tshuab ziab khaub ncaws tsis tas yuav tsum tau ua kom sov ua ntej lossis txias, vim tias cov hluav taws xob infrared tuaj yeem ua kom sov thiab txias cov khoom tam sim ntawd. Qhov no txo qhov kev pib thiab kaw lub sijhawm, thiab ua rau kom yooj yim dua thiab ua haujlwm ntawm cov kab ntau lawm.

• Kev siv hluav taws xob tsawg thiab cov khoom lag luam zoo: Lub tshuab ziab khaub ncaws IRD siv cov hluav taws xob infrared, uas yog ib txoj hauv kev ncaj qha thiab muaj txiaj ntsig ntawm cov khoom siv cua sov, tsis tas siv hluav taws xob rau cua sov lossis lub tshuab. Lub tshuab ziab khaub ncaws IRD kuj tseem siv lub sij hawm luv luv ziab thiab crystallization, uas txo cov kev siv zog thiab thermal degradation ntawm cov khoom. Lub tshuab ziab khaub ncaws IRD tuaj yeem ua tiav tus nqi qis zog ntawm 0.08 kWh / kg, yam tsis muaj kev cuam tshuam cov khoom zoo.

• Daim ntawv thov dav thiab kev ua haujlwm yooj yim: Lub tshuab ziab khaub ncaws IRD tuaj yeem ua ntau hom PET cov khoom, xws li regrind flake, virgin resin, zaj duab xis yob, lossis cov khoom sib xyaw. Lub tshuab ziab khaub ncaws IRD kuj tseem siv tau rau lwm cov ntaub ntawv yas, xws li PE, PP, PVC, ABS, PC, thiab PLA, nrog rau lwm yam khoom siv dawb-ntws, xws li cov nplaum, hmoov, thiab granules. Lub tshuab ziab khaub ncaws IRD yog ib qho yooj yim rau kev khiav lag luam thiab tswj, vim nws muaj cov qauv yooj yim, hneev taw me me, thiab cov neeg siv-phooj ywg interface.

• PLC tswj thiab kov npo interface: IRD Tshuab ziab khaub ncaws yog tswj los ntawm PLC system, uas muab tag nrho cov txheej txheem pom thiab tswj. PLC system tuaj yeem saib xyuas thiab kho cov txheej txheem tsis tu ncua, khaws thiab rov qab cov zaub mov txawv, thiab muab kev pabcuam online ntawm modem. Lub kaw lus PLC tseem muaj lub vijtsam kov, uas tso cai rau tus neeg teb xov tooj los teeb tsa thiab hloov cov txheej txheem kev ntsuas thiab ntsuas kub, thiab nkag mus rau cov ntaub ntawv thiab cov xwm txheej ntawm lub tshuab.

Lub tshuab ziab khaub ncaws IRD yog lub tshuab uas tuaj yeem txhim kho qhov ua tau zoo, zoo, thiab tau txais txiaj ntsig ntawm PET daim ntawv ntau lawm, los ntawm kev muab ceev ceev, ua haujlwm tau zoo, thiab sib xyaw kom qhuav thiab crystallization ntawm PET cov khoom hauv ib kauj ruam.

Xaus

IRD Tshuab ziab khaub ncaws rau PET daim ntawv ntau lawm kab yog lub tshuab siv hluav taws xob infrared thiab kev sib hloov ziab kom ua tiav ziab thiab crystallization ntawm PET regrind flake thiab nkauj xwb cob hauv ib kauj ruam. Lub tshuab ziab khaub ncaws IRD muaj ntau yam zoo dua li cov qauv siv, xws li tsis muaj kev sib cais ntawm cov khoom sib txawv ntawm cov khoom sib txawv, kev pib sai sai thiab kaw sai, kev siv hluav taws xob tsawg thiab cov khoom zoo, daim ntawv thov dav thiab ua haujlwm yooj yim, thiab PLC tswj thiab kov npo interface. Lub tshuab ziab khaub ncaws IRD yog ib qho kev daws teeb meem tshiab rau PET daim ntawv ua, tsim los ntawm LANDA, lub tuam txhab tshwj xeeb hauv cov khoom siv yas rov ua dua tshiab thiab ua cov khoom siv. IRD Tshuab ziab khaub ncaws yog ib yam khoom muaj txiaj ntsig thiab ntau yam hauv kev lag luam yas.

Yog xav paub ntxiv los yog nug, thovtiv tauj peb:

Email:sales@ldmachinery.com/liandawjj@gmail.com

WhatsApp: +86 13773280065 / +86-512-58563288

Post lub sij hawm: Dec-27-2023