PET Lub raj mis Flake Granulation Kab

PET Lub raj mis Recycling Pelletizer PET Granulation Tshuab Txheej txheem ntws

Technical Specification

|

Lub npe tshuab |

PET Ib Ntsia Hlau Extrusion pelletizing Kab |

|

Raw Khoom |

rPET Flakes |

|

Yam khoom kawg |

rPET pellets |

|

Cov kab ntau lawm | Infrared Crystal tshuab ziab khaub ncaws: Nqus feeder / Infrared siv lead ua tshuab / Nqus discharger

Ib Screw Extrusion granulating kab: Tib ntsia hlau lub ntsiab extruder / Hydraulic Ob chav Pistons tshuaj ntsuam hloov / Tuag lub taub hau / Flushing dej trough / Flushing pellitizer / Vertical dewatering tshuab / vibrating sieve tshuab / Cia

|

|

Ntsia taub hau |

90mm-150mm |

|

L/D |

1:24/1:30 dr hab |

|

Tso zis ntau yam |

150-1000KG / H |

|

Cov khoom siv ntsia hlau |

38CrMoAlA nrog Nitrding kho |

|

Hom Pelletizing |

Dej ntws tawm & pelletizing |

|

Screen hloov pauv |

Hydraulic Ob chav Pistons Screen Changer |

Tshuab Paub meej

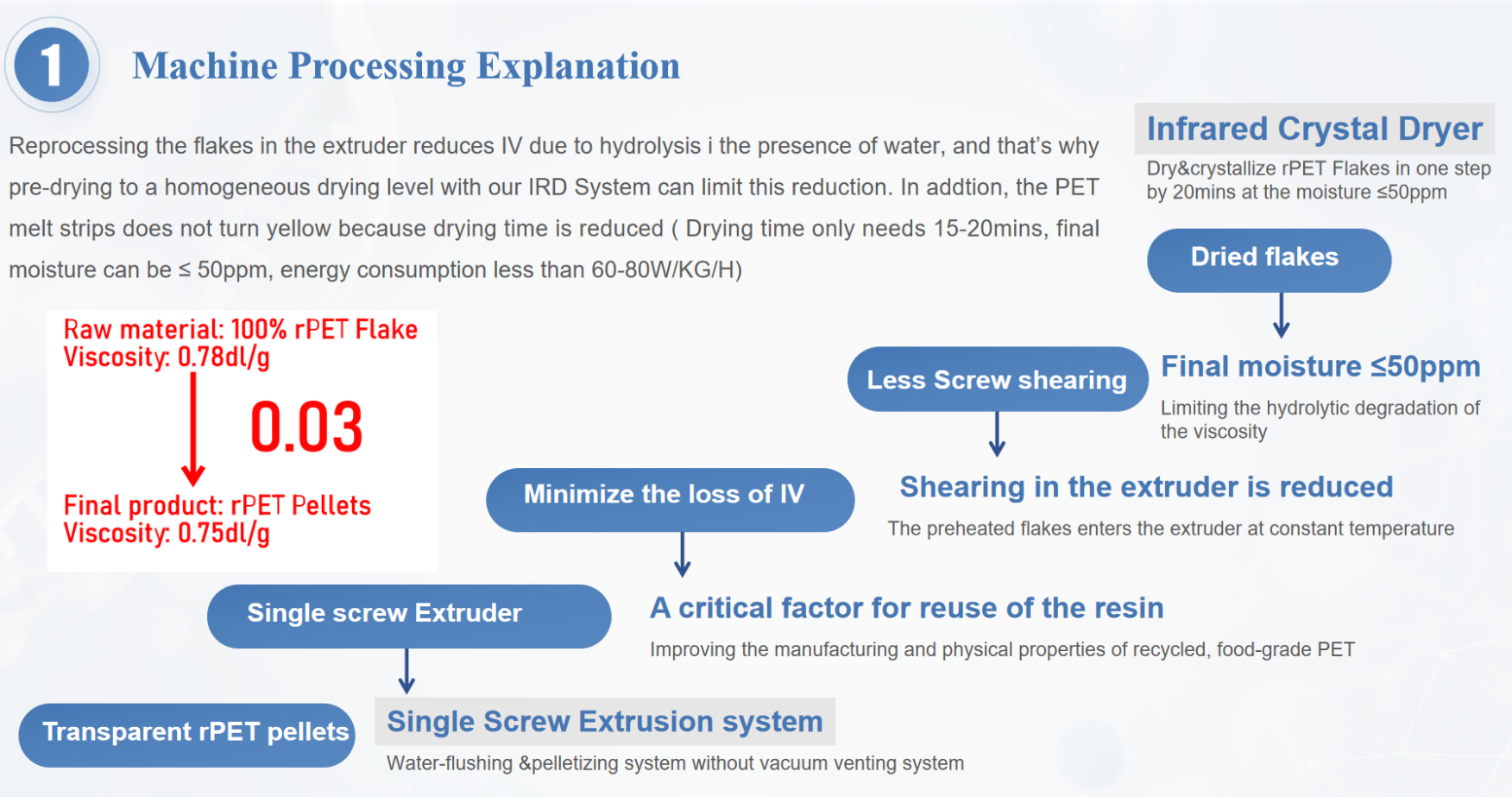

Infrared Crystal Dryer (LIANDA PATENT DESIGN)

① Txhim kho kev tsim khoom thiab lub cev ntawm cov khoom siv rov ua dua tshiab, qib PET los ntawm kev siv thev naus laus zis los ntawm infrared yoj muaj qhov tseem ceeb los ua si hauv cov khoom siv viscosity (IV)

②Pre-crystallization & ziab ntawm cov flakes ua ntej extrusion pab txo qhov poob ntawm IV los ntawm PET, qhov tseem ceeb rau kev rov siv cov resin

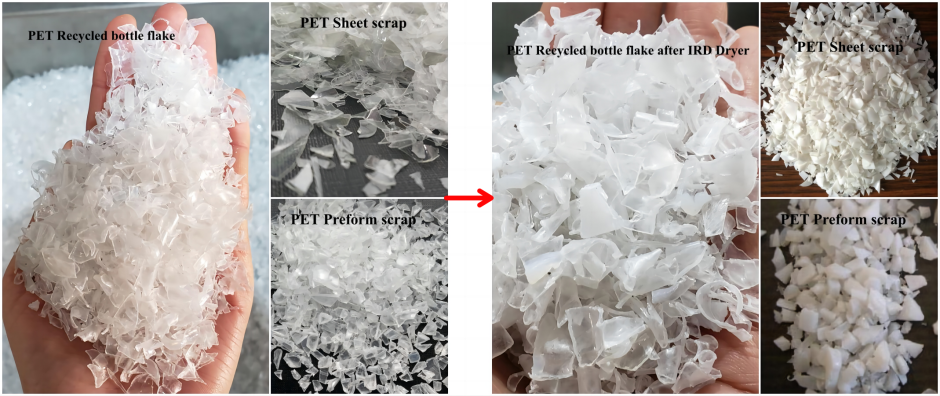

③Reprocessing cov flakes nyob rau hauv lub extruder txo IV vim hydrolysis nyob rau hauv lub xub ntiag ntawm dej, thiab yog vim li cas ua ntej ziab mus rau ib homogeneous ziab theem nrog peb IRD System yuav txo tau qhov no.

Tsis tas li ntawd, PET yaj strips tsis tig daj vim lub sij hawm ziab kom qhuav (Lub sij hawm ziab tsuas yog xav tau 15-20mins, qhov kawg ya raws tuaj yeem yog ≤ 30ppm, lub zog noj tsawg dua 60-80W / KG / H)

④ Shearing nyob rau hauv lub extruder yog li txo vim hais tias cov khoom preheated nkag mus rau hauv extruder ntawm qhov kub thiab txias "

⑤ Txhim kho cov zis ntawm PET Extruder

Kev nce ntawm qhov ceev ntawm 10 mus rau 20% tuaj yeem ua tiav hauv IRD, txhim kho kev ua haujlwm pub noj ntawm lub extruder inlet ntau - thaum lub extruder ceev tseem tsis hloov, muaj kev txhim kho kev ua tiav ntawm cov ntsia hlau.

Ib Screw Extrusion Pelletizing Kab (tsis muaj lub tshuab nqus tsev vacuum)

Siv lub zog ntawm Ib leeg ntsia hlau extruder thiab paring nws nrog LANDA tshwj xeeb tsim cov ntsia hlau rau rPET Lub raj mis flakes, peb tuaj yeem nce lub peev xwm los ntawm 20% nrog tsawg zog noj piv nrog Parallel ob lub ntsia hlau extruder.

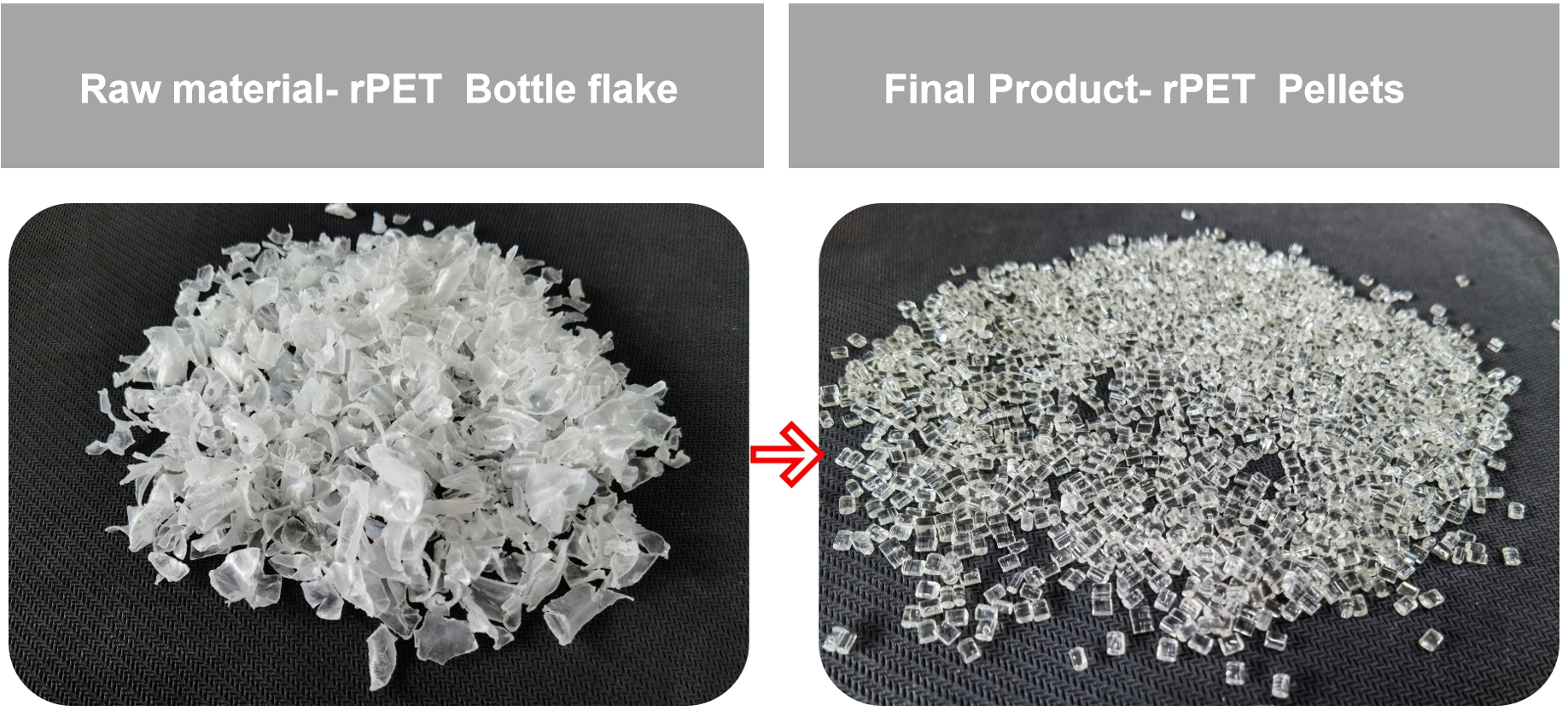

Viscosity ntawm rPET pellets tsim los ntawm peb lub cev: tsuas yog ≤0.02-0.03dl / g viscosity poob --- tsis ntxiv cov viscosity enhancer. (Raws li peb qhov kev sim hauv tsev)

rPET pellets Xim: pob tshab --- tsis ntxiv cov pob tshab ntxiv

Tsis muaj lub tshuab nqus tsev vacuum --- Txuag nqi hluav taws xob, tsis muaj teeb meem thiab ua haujlwm ruaj khov

Tshuab duab