Infrared Rotary Dryer maka ime PET Fiber

Nkọwa ngwaahịa

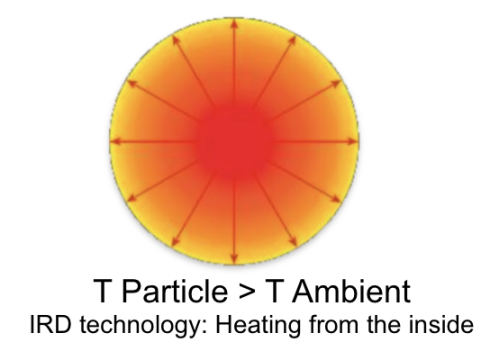

Ụzarị infrared nke na-abanye ma na-egosipụta site na ihe onwunwe adịghị emetụta nhazi nke ihe ahụ, ma anụ ahụ na-etinye aka na ya ga-agbanwe n'ime ike ọkụ n'ihi mkpali molekụla, nke na-eme ka okpomọkụ nke ihe na-ebili ngwa ngwa.

Kpoo ọkụ na isi. Site na ọkụ infrared dị mkpụmkpụ na-ekpo ọkụ na-ekpo ọkụ ozugbo n'ime

Site n'ime ruo n'èzí. Ike dị na isi na-ekpo ọkụ ihe site na

n'ime ime ya, ya mere, a na-esi n'ime ya na-esi n'ime ya pụta n'èzí nke ihe.

Evaporation nke mmiri.Mgbasa ikuku ọzọ n'ime igwe nkụ na-ewepụ mmiri mmiri na-ekpo ọkụ na ihe.

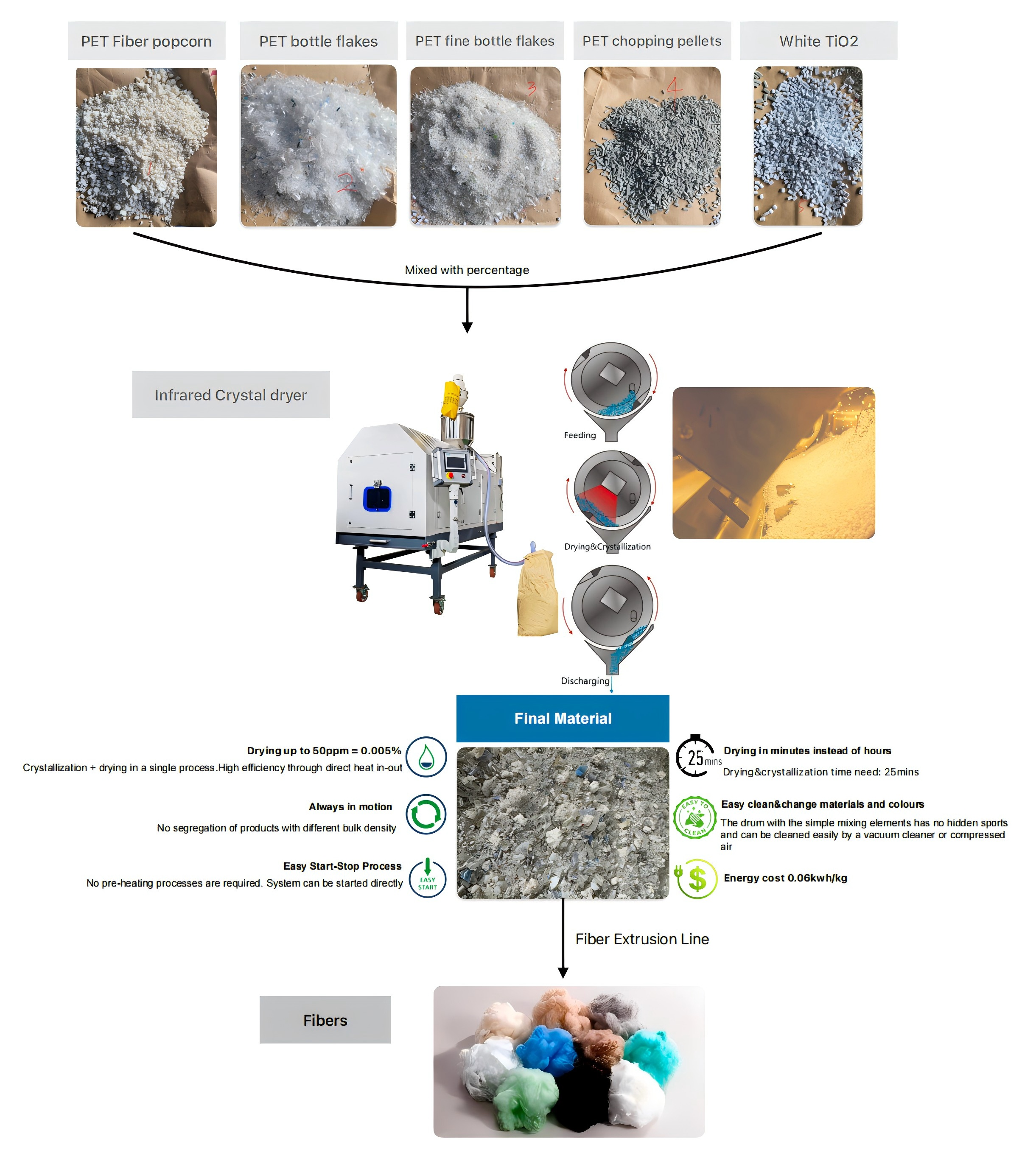

Ọmụmụ ihe

Egosiri nhazi

Uru ihe anyị na-eme na nhazi

①Mmalite ozugbo na mechie ngwa ngwa

→Mmalite ngwa ngwa nke mmepụta mmepụta ga-ekwe omume. Achọghị usoro ikpo ọkụ nke igwe

→ Enwere ike ịmalite nhazi, kwụsị ma malitegharịa ngwa ngwa

② Na-emegharị mgbe niile

→ Enweghị nkewa nke ngwaahịa nwere nnukwu njupụta dị iche iche

→ The perment ntụgharị nke drum na-eme ka ihe na-aga n'ihu na clumping nwere ike zere

③ ihicha n'ime nkeji kama awa (ịkpọ nkụ&crystalization oge mkpa: 25mins)

→Infrared ụzarị kpatara molekụla thermal pscillations nke na-arụ ọrụ ozugbo na isi nke ahụ si n'ime pụta. nke mere na mmiri dị n'ime ihe ndị ahụ na-ekpo ọkụ ngwa ngwa ma wepụ ya n'ime ikuku ikuku na-ekesa, na-ewepụkwa mmiri n'otu oge ahụ.

④ Na-emeziwanye mmụba nke PET Extruder

→ Enwere ike nweta mmụba nke nnukwu njupụta site na 10-20% na sistemụ IRD, melite arụmọrụ nri na ntinye nke extruder nke ukwuu, ebe ọsọ extruder na-agbanweghị agbanwe, enwere arụmọrụ njuputa nke ọma na ịghasa.

⑤ Dị mfe dị ọcha&gbanwe ihe na agba

→ Drum nwere ihe ngwakọta dị mfe enweghị egwuregwu zoro ezo, enwere ike ihicha ya ngwa ngwa site na igwe na-ehicha ihe ma ọ bụ ikuku abịakọrọ.

⑥ Ike na-eri 0.06kwh/kg

→ obere oge obibi = nnukwu usoro mgbanwe

→ ike n'otu n'otu na-agbanwe agbanwe --- Enwere ike ijikwa oriọna ọ bụla site na mmemme PLC

FAQ

a.Gịnị bụ oke na mmiri mbụ nke akụrụngwa?

→ Enweghị mmachi zuru oke na mmiri mbụ, 2%,4% dị mma

b. Kedu mmiri ikpeazụ nwere ike nweta mgbe akpọnwụchara?

→ ≦30ppm

c.Gịnị bụ ihicha&crystalization oge mkpa?

→ 25-30 nkeji. A ga-emecha ihicha & crystallized n'otu nzọụkwụ

d.Gịnị bụ isi iyi ọkụ? Ikuku kpọrọ nkụ dị ala igirigi?

→ Anyị na-anakwere oriọna infrared (infrared wave) dị ka isi iyi ọkụ. Site na ọkụ infrared dị mkpụmkpụ na-ekpo ọkụ na-ekpo ọkụ ozugbo site n'ime ya n'èzí. Ike dị na isi na-eme ka ihe dị n'ime ya na-ekpo ọkụ, n'ihi ya, mmiri na-esi n'ime ya pụta n'èzí nke ihe ahụ.

e. A ga-edobe ihe njupụta dị iche iche na-ahụ maka nhazi ihicha?

→ The perment ntụgharị nke drum na-eme ka ihe na-aga n'ihu, - Ọ dịghị nkewa nke ihe dị iche iche nnukwu njupụta mgbe nri na extruder.

f. Gịnị bụ ihicha okpomọkụ?

→ The ihicha okpomọkụ set akporo: 25-300 ℃. Dị ka PET, anyị na-atụ aro ịmụta banyere 160-180 ℃

g. Ọ dị mfe ịgbanwe agba masterbatch?

→ The drum na mfe ịgwakọta ihe enweghị egwuregwu zoro ezo, dị mfe ịgbanwe ihe ma ọ bụ agba materbatch

h.Kedu ka i si eme ntụ ntụ?

→ Anyị nwere uzuzu uzuzu nke ga-arụ ọrụ na IRD ọnụ

I. Gịnị bụ ndụ teta nke oriọna?

→ 5000-7000awa. (Ọ pụtaghị na oriọna ahụ enweghị ike ịrụ ọrụ ọzọ, naanị mbelata ike

J. Gịnị bụ oge nnyefe?

→ 40 ụbọchị ọrụ mgbe enwetara nkwụnye ego

ọ bụrụ na ị nwere nkọwa ndị ọzọ ị ga-achọ ịma, biko zitere anyị ozi-e:

Na-agba ọsọ na nkọwa ụlọ ọrụ ndị ahịa

Ọrụ anyị

Anyị factory nwere wu Test Center. N'ime ụlọ nyocha anyị, anyị nwere ike ịme nnwale na-aga n'ihu ma ọ bụ kwụsịchaa maka ihe nlele ndị ahịa. Ejiri akụrụngwa akpaaka zuru oke yana teknụzụ nha.

- Anyị nwere ike igosi --- Nbugharị/Nbudata, ihicha& kristal, ịwụsa.

- Ihicha na kristal nke ihe iji chọpụta mmiri fọdụrụnụ, oge obibi, ntinye ike na ihe onwunwe.

- Anyị nwekwara ike igosi arụmọrụ site n'inweta nkwekọrịta maka obere obere.

- Dị ka ihe onwunwe na mmepụta ihe chọrọ, anyị nwere ike ịdepụta atụmatụ gị.

Injinia nwere ahụmahụ ga-eme ule ahụ. A na-akpọ ndị ọrụ gị nke ọma ka ha sonye na ụzọ nkwonkwo anyị. N'ihi ya, ị nwere ma ekwe omume inye aka ifịk ifịk na ohere n'ezie ịhụ anyị ngwaahịa na-arụ ọrụ.