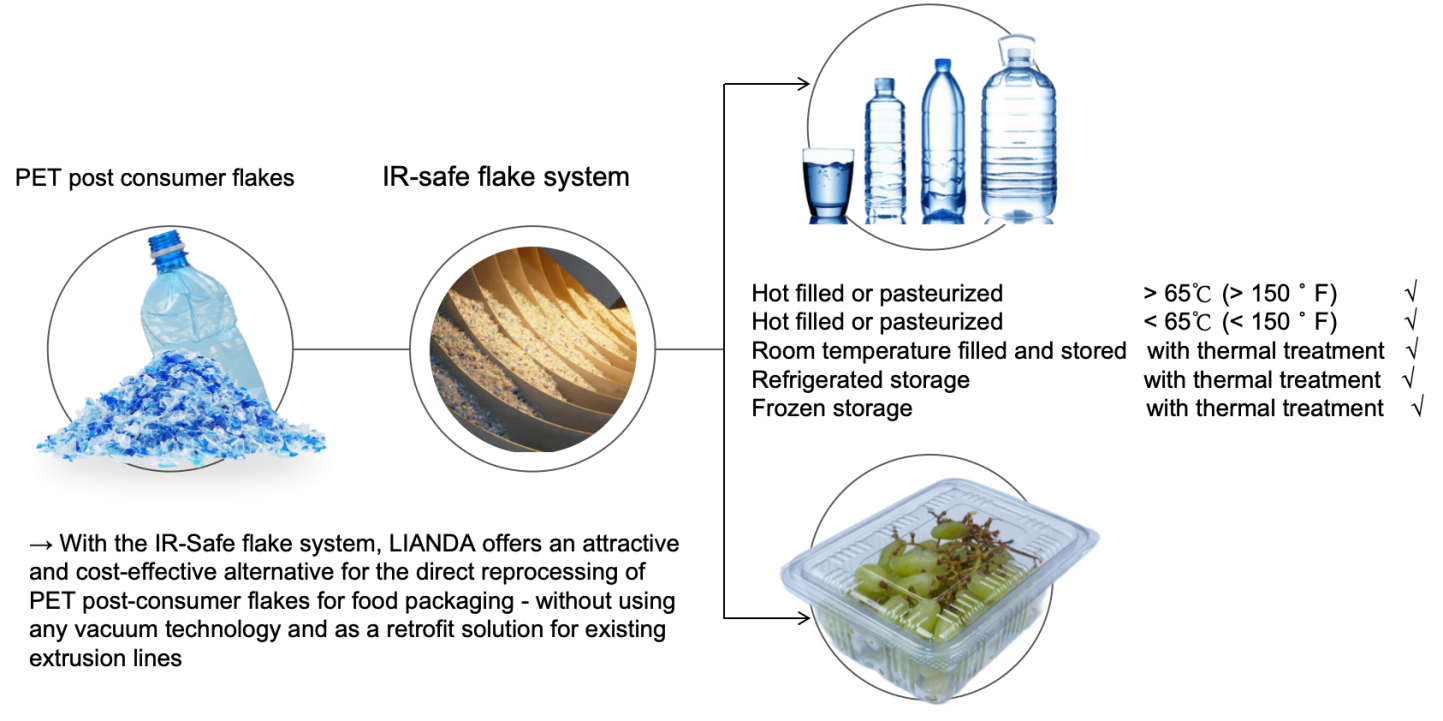

IR-Safe flake system — PET Decontamination for direct food contact packaging

Product Details

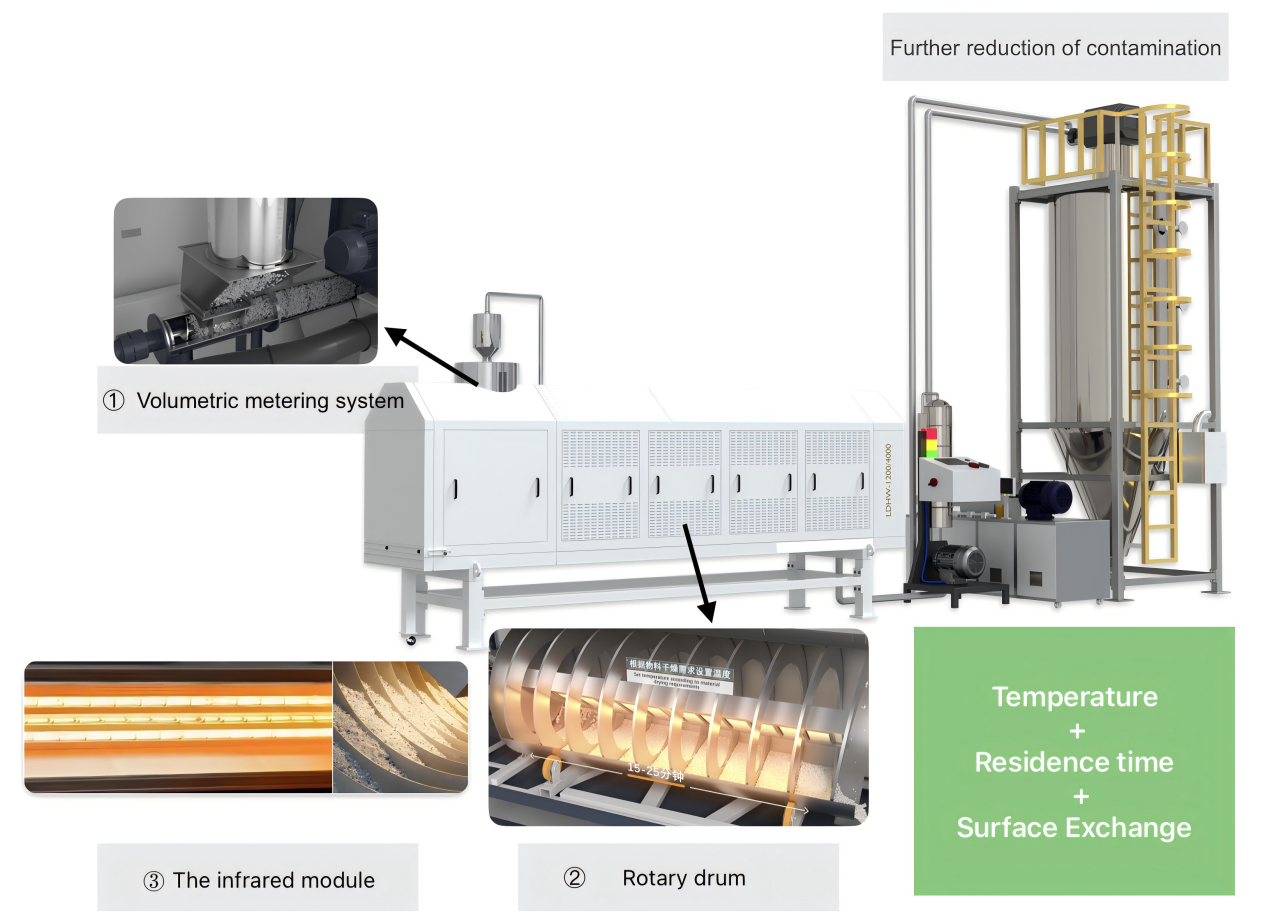

IR-safe flake working step

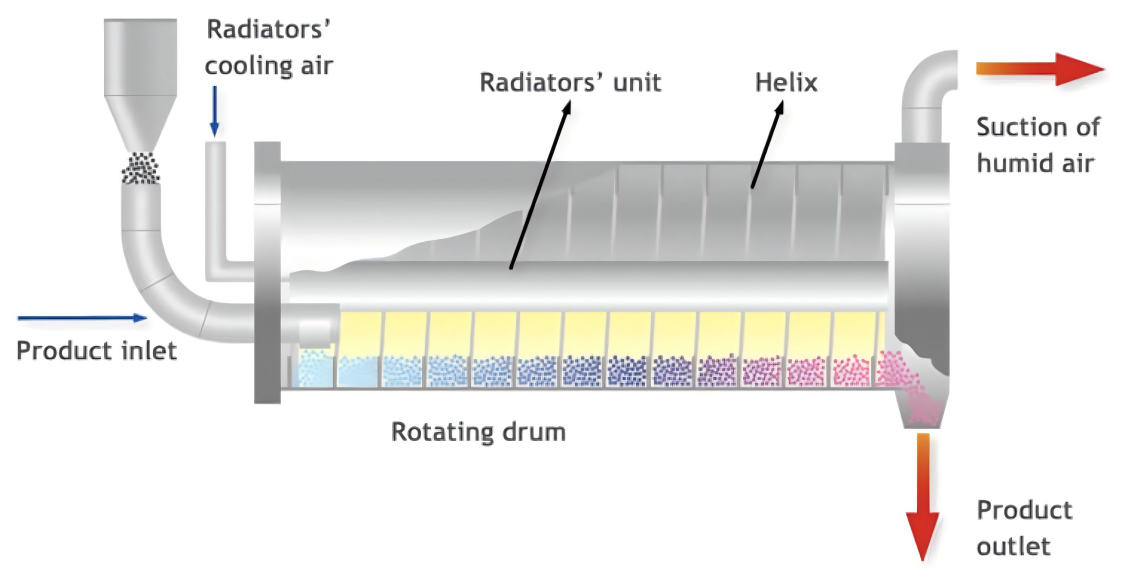

①The consumer PET flakes will be conveyed to the feeding hopper of the IR-safe flake system and fed into the rotary drum via the volumetric metering system.

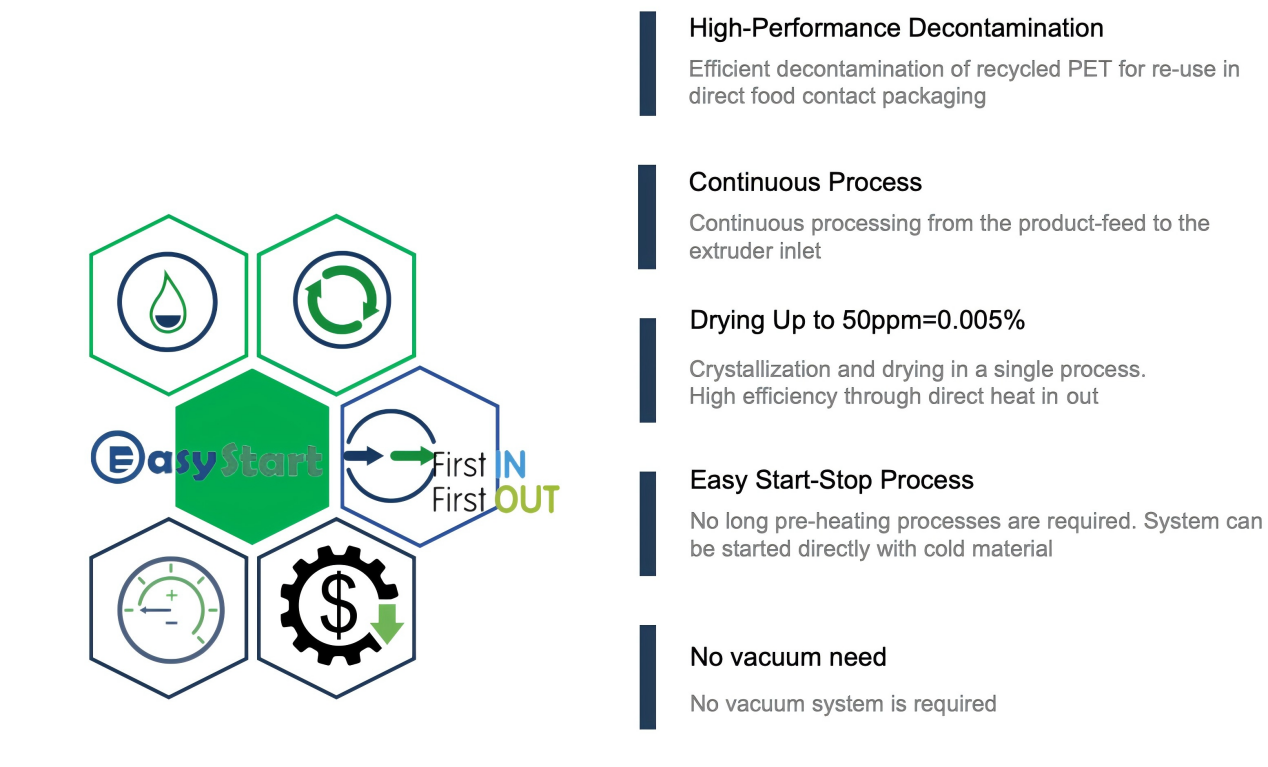

② The internal helix welded into the rotary drum ensures a homogeneous mass flow with a defined residence time (the first-in / first-out principle). Due to the rotation of the rotary drum and mixing elements integrated in the coils, the material is continuously mixed with simultaneous, constant surface exchange.

③The infrared module installed above the material bed heats the material quickly and directly to a high temperature level

④The moisture-laden air is discharged from the Rotary drum through a constant air stream. After minutes, rather than hours, the material exits the Rotary drym and is available for the next process step

⑤ The combination of the Infrared cleaning system with a finisher in the form of a desiccant dryer enables a further reduction of contamination, and has the added benefit of reduction to < 50 ppm of residual moisture.

Advantage we make

Machine photos

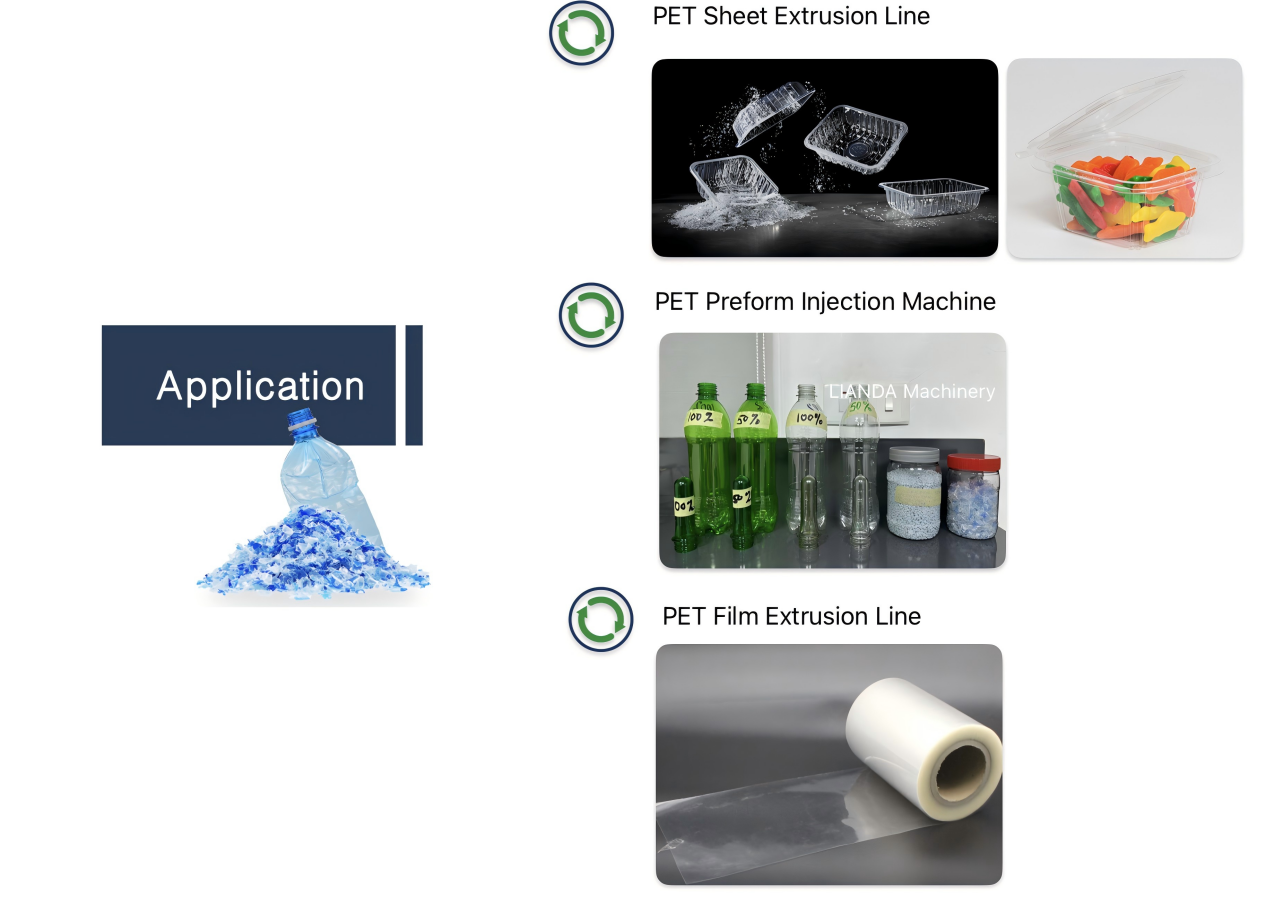

Application