Leading Manufacturer for Plastic Lumps Shredder Machine - Single shaft shredder/ Waste plastic shredder/ Plastic recycling machine – LIANDA

Leading Manufacturer for Plastic Lumps Shredder Machine - Single shaft shredder/ Waste plastic shredder/ Plastic recycling machine – LIANDA Detail:

Single shaft shredder

The single-shaft shredder is mainly used to break materials into smaller and uniform pieces.

>>LIANDA single-shaft shredder is equipped with a large inertia blade roller and a hydraulic pusher, which can ensure high output; the moving knife and the fixed knife have high-efficiency and regular cutting actions, and coordinate with the control of the sieve screen,the crushed material can be cut into the expected size.

>>the shredding of almost all types of plastic. Plastic lumps, pipes, automotive scrap, blow-molded materials (PE/PET/PP bottles, buckets, and containers, pallet), as well as paper, cardboard, and light metals.

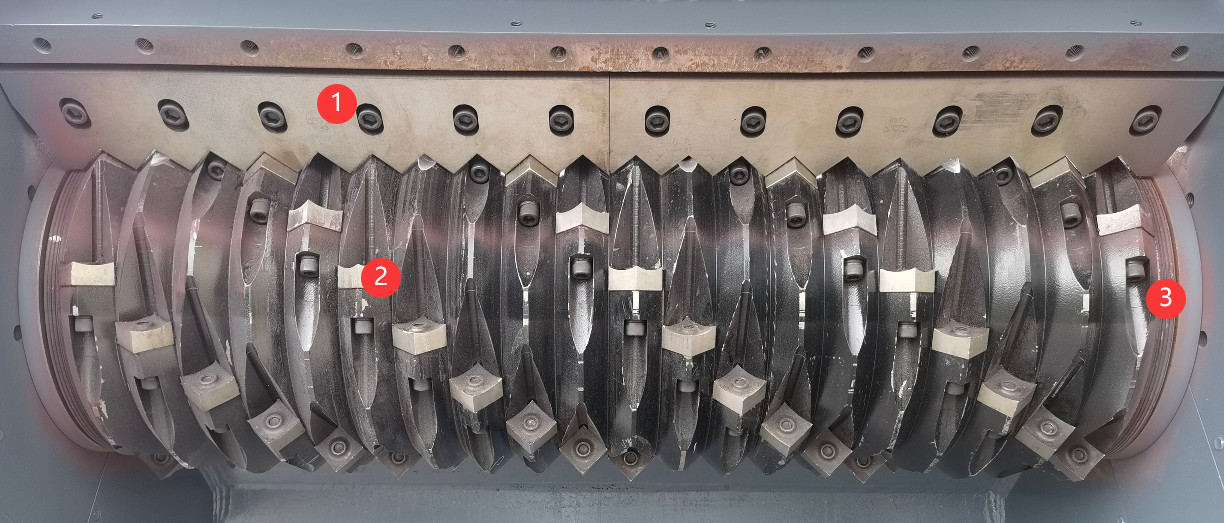

Machine Details Shown

①Stable blade ② Rotary blades

②Blade roller ④ Sieve screen

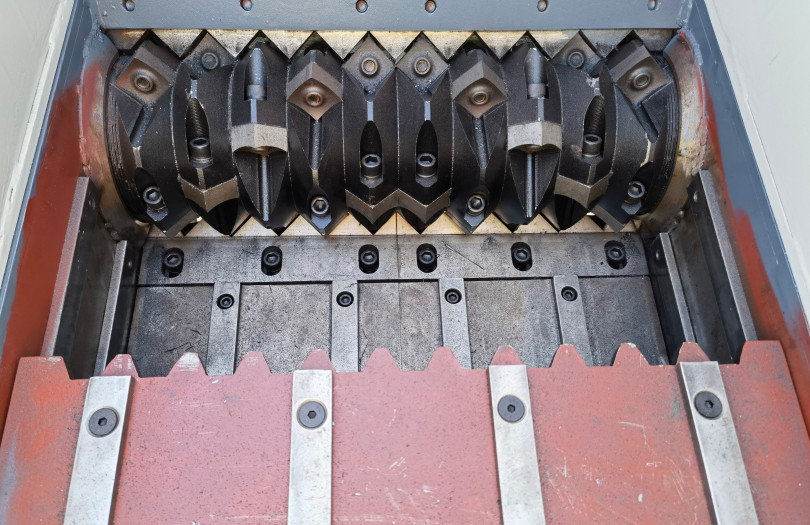

>>The cutting part is composed of a blade roller, rotary blades, fixed blades and sieve screen.

>>The V rotor, specially developed by LIANDA, can be used universally. Its aggressive material feed with up to two rows of knives guarantees high throughput with low power requirements.

>>The screen can be disassembled and replaced to change the particle size of the material

>>Screen can be exchanged flexibly and are bolted as standard.

>>Safe material feed with load-controlled ram

>>The ram, which moves horizontally back and forth via hydraulics, feeds the material to the rotor.

>> Knives in edge lengths of 30 mm and 40 mm. These can be turned over several times in case of wear, which drastically reduces maintenance costs.

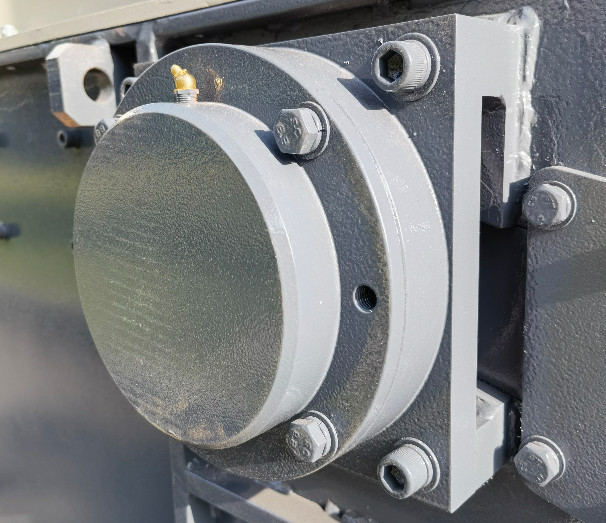

>>Durable rotor bearings thanks to offset design, to prevent dust or foreign matter from getting inside

>> Maintenance-friendly and easy to access.

>>Easy operation by Siemens PLC control with touch display

>>The built-in overload protection also prevents defects in the machine.

Machine Technical parameter

|

Model |

Motor Power (KW) |

Qty of Rotary Blades (PCS) |

Qty of Stable Blades (PCS) |

Rotary Length (MM) |

|

LDS-600 |

22 |

26 |

2

|

600 |

|

LDS-800 |

55 |

45 |

4

|

800 |

|

LDS-1200 |

75 |

64 |

4

|

1200 |

|

LDS-1600 |

132 |

120 |

4

|

1600 |

Application Samples

Plastic lumps

Baled Papers

Wood pallet

Plastic drums

Plastic drums

PET Fiber

KEY FEATURES >>

>>Large diameter flat rotor

>>Machined knife holders

>>Optional hard face

>>Concave ground square knives

>>Robust ram construction

>>Heavy duty guide bearings

>>Universal couplings

>>Low speed, high torque geared drive

>>Powerful hydraulic swing type ram

>>Bolt in driven shafts

>>Multiple rotor designs

>>Ram comb plate

>>Amp meter control

OPTIONS >>

>>Motor power source

>>Sieve screen type

>>Sieve screen need or not

Machine Photos

Product detail pictures:

Related Product Guide:

"Quality initially, Honesty as base, Sincere company and mutual profit" is our idea, in order to create repeatedly and pursue the excellence for Leading Manufacturer for Plastic Lumps Shredder Machine - Single shaft shredder/ Waste plastic shredder/ Plastic recycling machine – LIANDA, The product will supply to all over the world, such as: Poland, Swiss, Madras, We mainly sell in wholesale, with the most popular and easy ways of making payment, which are paying via Money Gram, Western Union, Bank Transfer and Paypal. For any further talk, just feel free to contact our salesmen, who are really good and knowledgeable about our prodcuts.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly