Manufacturer for Small Scale Plastic Recycling Plant - Film compacting granulating line/Shredder integrated recycling machine/PP raffia bag pelletizing line/Plastic recycling machine – LIANDA

Manufacturer for Small Scale Plastic Recycling Plant - Film compacting granulating line/Shredder integrated recycling machine/PP raffia bag pelletizing line/Plastic recycling machine – LIANDA Detail:

One step technology for PP raffia, woven and PE/PP Film waste

The film recycling granulator designed by LIANDA MACHINERY adopts the production mode of crushing, hot-melt extrusion, pelletizing and drying, which solves the problem:

■ The risk of manual feeding

■ Forced feeding capacity is small

■ The manual consumption of the split operation of crushing and extrusion is large

■ The particle size of the strands is not uniform, and the strands are easily broken

The film granulation equipment adopts the method of compaction&crushing. After the material is fed to the compactor, it will be crushed by the bottom cutter head, and the friction generated by the high-speed cutting of the cutter head generates heat, so that the material is heated and shrunk to increase the bulk density of the material and increase the feeding amount. This process method has a great help to increase production capacity

Machine Specifications

|

Machine Name |

Film compacting granulating line |

|

Final Product |

Plastic Pellets/granule |

|

Production line Components |

Conveyor belt, cutter compactor barrel, extruder, pelletizing unit, water cooling unit, drying unit, silo tank |

|

Application Material |

HDPE, LDPE, LLDPE, PP, BOPP, CPP, OPP, PA, PC, PS, PU, EPS |

|

Feeding |

Conveyor belt (Standard), Nip roll feeder (Optional) |

|

Screw diameter |

65-180mm |

|

Screw L/D |

30/1; 32/1;34/1;36/1 |

|

Output range |

100-1200kg/h |

|

Screw material |

38CrMoAlA |

|

Degassing |

Single or double vented degassing, Unvented for non-printed film (customized) Two stage type (mother-baby extruder) for even better degassing |

|

Cutting type |

Water ring die face cutting or strand die |

|

Screen changer |

Double work position hydraulic screen changer non stop or customized |

|

Cooling type |

Water-cooled |

Machine Details Shown

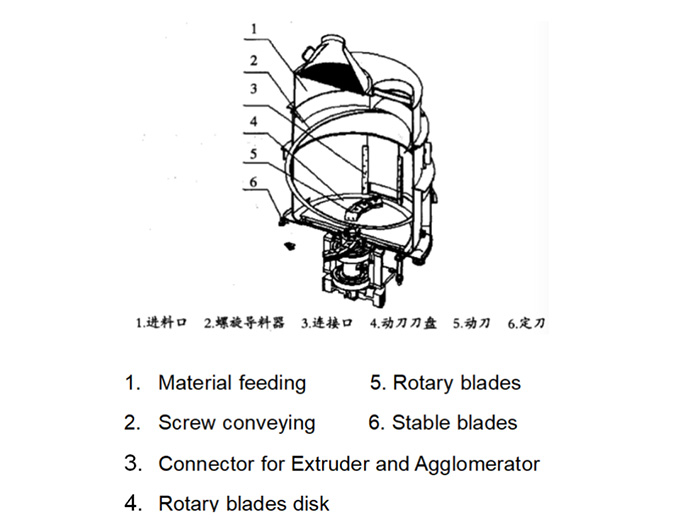

>> Film compactor/Agglomerator will cut film and compact the film by High speed friction

>> The Film compaction/ agglomerator is designed with observation window to facilitate customers to open,clean and change the blades

>> After the material enters the compactor, it is crushed and compacted, and the high-speed rotating compactor throws the material into the single-screw extruder along the flow path. A higher temperature can be created in the compactor, compacting the plastic into the pellets and

>>Water-ring pelletizer, pelletizing speed is controlled by inverter,including hot cutting die, diverter cone, water-ring cover,knife holder,knife disc,knife bar etc

>>Non-stop hydraulic screen changer, there is a pressure sensor on the die head to prompt screen change, no need to stop for screen change, and fast screen change

>> The pellets will be cut directly on the water-ring die head, and pellets will be fed to the Vertical dewatering machine after water cooled, the problem of strands breakage will not occur;

Controlling System

■ Feeding: Belt conveyor runs or not depends on the electric Currency of Film Compactor/Agglomerator. The Belt conveyor will stop conveying while the electric current of Film compactor/ agglomerator is over the set value.

■ Temperatur of Film Compactor/Agglomerator: The temperature generated by the friction of the material must ensure that the material is heated, curled, contracted, and enters the extruder smoothly, and has a certain bearing on the rotation speed of the compactor motor

■ Screw extruder speed can be adjustable ( According to the cituation of fed material)

■ Pelletizing speed can be adjustable (According to the material output and size)

Product detail pictures:

Related Product Guide:

"Quality initial, Honesty as base, Sincere support and mutual profit" is our idea, so as to build repeatedly and pursue the excellence for Manufacturer for Small Scale Plastic Recycling Plant - Film compacting granulating line/Shredder integrated recycling machine/PP raffia bag pelletizing line/Plastic recycling machine – LIANDA, The product will supply to all over the world, such as: Ecuador, Belgium, London, We win many reliable customers by rich experience, advanced equipments, skilled teams, strict quality control and best service. We can guarantee all our products. Customers' benefit and satisfaction are always our biggest goal. Please contact us. Give us a chance, give you a surprise.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.