As plastic recycling becomes increasingly critical, selecting the right equipment for efficient and effective recycling operations is essential. Among the essential tools, plastic dryers stand out for their ability to remove moisture from recycled plastic materials, enhancing the quality of the final product. ZHANGJIAGANG LIANDA MACHINERY CO., LTD. offers a range of advanced plastic dryers, including our specialized infrared crystal dryer, tailored to optimize recycling operations. Let’s dive into how different plastic dryers work and why our infrared crystal dryer may be the perfect solution for your recycling needs.

The Role of Plastic Dryers in Recycling

Drying plastic is a necessary step in the recycling process because residual moisture can impact the quality and structural integrity of recycled plastics. The right plastic dryers for recycling applications can ensure consistent moisture removal, leading to stronger, more reliable end products. For industries that demand precision and high performance, choosing the appropriate drying technology is crucial to achieving operational success.

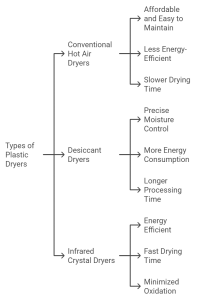

Types of Plastic Dryers for Recycling

1.Conventional Hot Air Dryers

Hot air dryers are commonly used for general drying needs. They work by blowing heated air through the plastic granules, which effectively removes surface moisture. However, while hot air dryers are affordable and easy to maintain, they may not offer the same energy efficiency or drying speed required for high-volume recycling operations. This is where advanced solutions, like infrared crystal dryers, step in.

2.Desiccant Dryers

Desiccant dryers are known for their precise moisture control, which is ideal for engineering-grade plastics requiring low humidity levels. These dryers circulate air through a desiccant material, which absorbs moisture effectively. However, they can consume more energy and have a longer processing time, making them less suitable for rapid recycling operations where time and energy costs are key considerations.

Our infrared crystal dryer represents a cutting-edge solution specifically designed for recycling plastics. By using infrared radiation to directly penetrate plastic particles, this dryer can rapidly evaporate moisture. It delivers outstanding energy efficiency and reduced drying time, making it ideal for high-volume recycling. Additionally, infrared drying minimizes oxidation risk, preserving the quality of the recycled material.

Why Choose an Infrared Crystal Dryer for Your Recycling Process?

The infrared crystal dryer by ZHANGJIAGANG LIANDA MACHINERY CO., LTD. offers several advantages over traditional dryers, particularly for recycling applications:

Rapid Drying and Energy Efficiency

Our infrared crystal dryer uses targeted infrared radiation to achieve rapid moisture removal, significantly reducing energy consumption compared to other drying methods. This not only cuts down on operational costs but also supports eco-friendly practices by minimizing energy waste.

Consistent Quality and Protection Against Oxidation

The fast-drying process prevents prolonged exposure to heat, reducing the risk of oxidation that can degrade recycled materials. This results in consistently high-quality output suitable for a wide range of recycled plastic applications.

Low Maintenance and Easy Operation

Designed with user-friendly controls, the infrared crystal dryer requires minimal maintenance, making it a cost-effective and hassle-free option for industrial recycling processes.

Applications and Industries Benefiting from Infrared Crystal Dryers

The versatility of infrared crystal dryers makes them suitable for various applications within the recycling sector. Industries recycling PET, HDPE, PP, and other thermoplastics find this technology beneficial due to its speed and efficiency. With faster throughput, companies can handle larger volumes, making it ideal for facilities aiming to maximize output while maintaining quality.

Conclusion: Optimizing Your Recycling Process with the Right Dryer

Choosing the right plastic dryer for recycling can make a substantial difference in both the quality and cost-effectiveness of your operations. ZHANGJIAGANG LIANDA MACHINERY CO., LTD.’s infrared crystal dryer offers a high-performance, energy-efficient solution for companies seeking advanced plastic dryers for recycling. Whether you need to optimize drying speed, reduce energy consumption, or ensure high-quality results, our infrared crystal dryer is designed to meet the most demanding recycling needs. For more information on how our infrared crystal dryer can support your business, visit our product page.

Post time: Oct-30-2024