News

-

How to Choose the Best Crusher Machinery for Your Needs?

In the dynamic world of construction, mining, and quarrying, crusher machinery stands as an indispensable tool for transforming rocks and minerals into valuable aggregates. Selecting the right crusher machinery for your specific needs is crucial for optimizing productivity, ensuring consistent pr...Read more -

Common Crusher Machinery Problems and Solutions: A Troubleshooting Guide

In the realm of construction, mining, and quarrying, crusher machinery plays a crucial role in reducing rocks and minerals into usable aggregates. However, these powerful machines, like any other piece of equipment, can encounter various issues that hinder their performance and productivity. This...Read more -

Essential Crusher Machinery Maintenance Tips: Ensuring Smooth Operations and Extended Lifespan

In the realm of construction, mining, and quarrying, crusher machinery plays a pivotal role in reducing rocks and minerals into usable aggregates. These powerful machines, however, require regular maintenance to ensure optimal performance, extended lifespan, and safety. This comprehensive guide d...Read more -

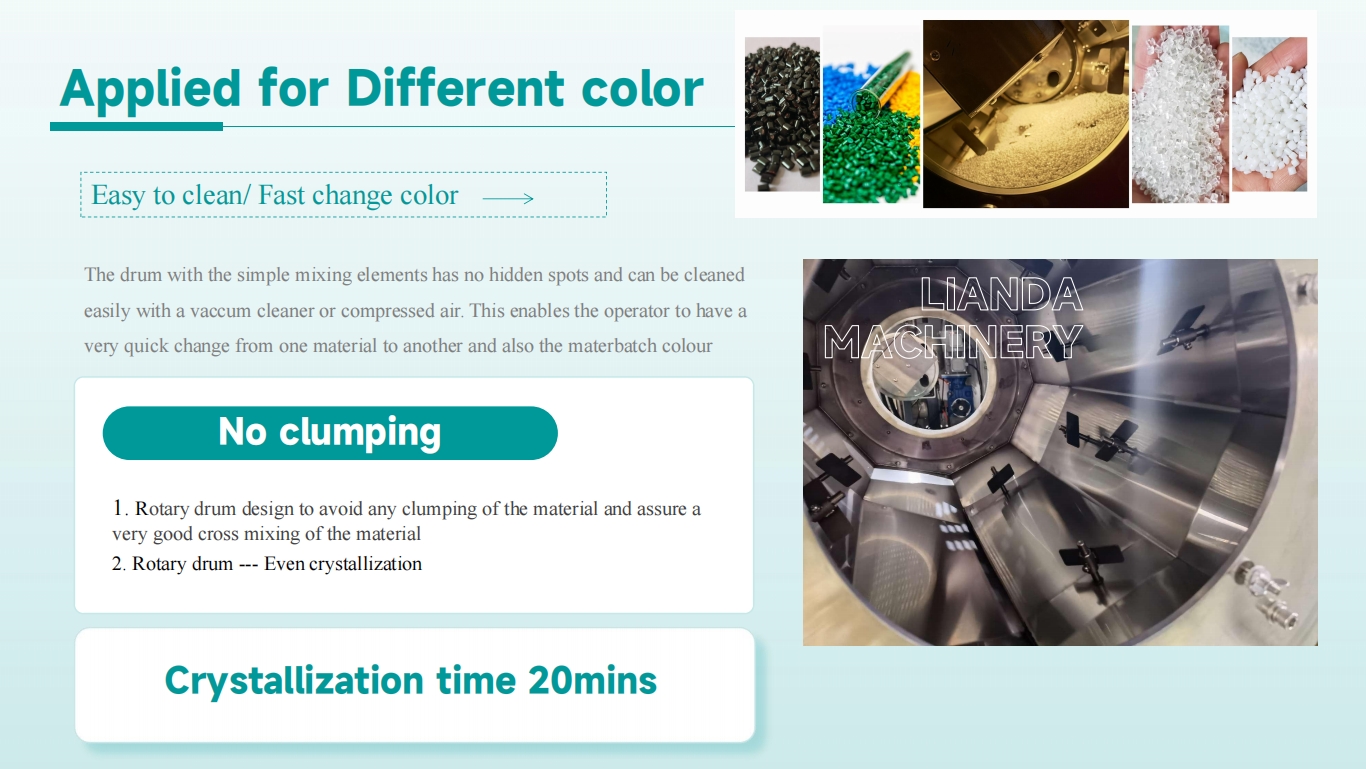

Polyester Masterbatch Crystallizer Dryer: The Epitome of Efficiency and Precision

LIANDA MACHINERY, a name synonymous with innovation, introduces the Polyester Masterbatch Crystallizer Dryer, a cutting-edge solution designed to streamline the drying and crystallization process of polyester masterbatches. This machine is a testament to LIANDA’s commitment to advancing the...Read more -

Plastic Desiccant Dehumidifier: A Leap Forward in Material Processing

LIANDA MACHINERY is proud to introduce the Plastic Desiccant Dehumidifier, a state-of-the-art solution designed for the efficient and effective treatment of PET pellets made from recycled flakes. This innovative machine sets new standards in the industry, offering unparalleled performance in the ...Read more -

PETG Dryer: Pioneering Precision Drying Technology

In the realm of plastic production, LIANDA MACHINERY stands out with its innovative PETG Dryer, designed to tackle the inherent stickiness of PETG materials. The dryer ensures that the final product is free from clumping and sticking, a testament to LIANDA’s commitment to quality and effici...Read more -

Elevating Efficiency with the PLA Crystallizer Dryer

LIANDA MACHINERY is proud to introduce the PLA Crystallizer Dryer, a groundbreaking solution in the realm of polymer processing. This state-of-the-art equipment represents the pinnacle of drying technology, offering unparalleled efficiency and performance. Innovative Infrared Technology The infra...Read more -

Revolutionizing PET Flake/Scrap Processing with Advanced Dehumidifier Crystallizer

LIANDA MACHINERY is transforming the PET recycling industry with its innovative PET Flake/Scrap Dehumidifier Crystallizer. This cutting-edge system is designed to address the critical challenges faced during the reprocessing of PET flakes and scrap, ensuring superior quality and efficiency. Optim...Read more -

TPEE Dryer & VOC Cleaner – Revolutionizing Polymer Devolatilization

LIANDA MACHINERY introduces the innovative TPEE Dryer & VOC Cleaner, a revolutionary system utilizing infrared drying technology for superior polymer devolatilization. This article delves into the system’s detailed properties and performance, highlighting its numerous benefits. The Powe...Read more -

The Revolutionary Polyester/PET Masterbatch Infrared Crystallization Dryer

LIANDA MACHINERY is at the forefront of innovation with our state-of-the-art Polyester/PET Masterbatch Infrared Crystallization Dryer. This advanced machinery is specifically designed to address the challenges faced in the drying and crystallization of PET Masterbatch, ensuring a seamless and ef...Read more -

Unveiling the Efficiency: A Deep Dive into Film Squeezing Pelletizing Dryer

LIANDA MACHINERY steps forward with a revolutionary solution for plastic waste recycling – the Film Squeezing Pelletizing Dryer. This innovative machine transforms used plastic films, woven bags, PP Raffia bags, and PE film into valuable plastic granulates, promoting sustainability and minimizing...Read more -

Revolutionizing PET Strap Production: The Innovative Plastic PET Strap Production Line

In the world of packaging, the strength and reliability of materials are paramount. The Plastic PET Strap Production Line stands at the forefront of this industry, providing a robust solution for producing PET straps. This article delves into the intricate process and the cutting-edge technology ...Read more