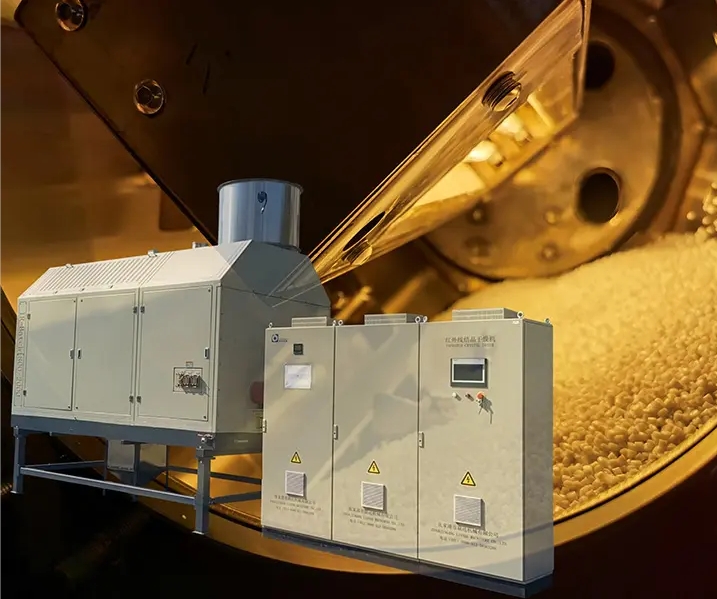

LIANDA MACHINERY is a globally recognized plastic recycling machine manufacturer. One of our innovative products is the rPET pallets Crystallization Dryer, which is designed to process recycled PET flakes, chips, or pellets into high-quality materials for various applications.

The rPET pallets Crystallization Dryer is based on the infrared rotary drum technology, which can achieve both crystallization and drying in one step, in less than 20 minutes, and with up to 60% less energy consumption than conventional drying systems. The rPET pallets Crystallization Dryer can handle different types and grades of PET materials, such as virgin, mixed, or colored, and produce uniform, milk-white, and low-moisture (less than 50 ppm) products.

The rPET pallets Crystallization Dryer has many advantages over traditional drying methods, such as:

• The rPET pallets Crystallization Dryer can prevent the hydrolysis degradation of the viscosity and the increase of acetaldehyde levels, which are important for food-grade applications.

• The rPET pallets Crystallization Dryer can increase the production capacity by up to 50%, as it eliminates the need for pre-drying and reduces the residence time in the extruder.

• The rPET pallets Crystallization Dryer can improve and stabilize the product quality, as it ensures a consistent and repeatable input moisture content and crystallization rate.

• The rPET pallets Crystallization Dryer can save up to 45-50% of energy costs, as it uses infrared radiation to heat up the material directly, without the need for hot air or desiccant.

• The rPET pallets Crystallization Dryer can save up to 300% of space, as it combines two processes in one compact machine, without the need for hoppers, silos, or conveyors.

• The rPET pallets Crystallization Dryer can facilitate the quick change-over and shutdown of the production line, as it has an instant start-up and shut-down feature, and an easy-clean and material-change function.

• The rPET pallets Crystallization Dryer can operate independently or integrate with other machines, such as extruders, pelletizers, or injection molding machines, to form a complete production line.

The rPET pallets Crystallization Dryer is controlled by a Siemens PLC touch screen, which has a memory function and a one-key start feature. The machine has three PID temperature control zones, which can be adjusted according to the characteristics of the raw materials. The machine also has a rotary working style, which can act as a mixer, allowing the user to feed different proportions of PET chips and recycled pellets directly, without the need for pre-mixing.

The rPET pallets Crystallization Dryer is a revolutionary product that can help the plastic recycling industry to achieve higher efficiency, lower costs, and better quality. LIANDA MACHINERY is committed to providing the best solutions for plastic recycling and reprocessing, and to contributing to a sustainable and circular economy.

For more information about the rPET pallets Crystallization Dryer, please contact us at sales@ldmachinery.com / liandawjj@gmail.com. You can also check out some of other products, such as the PET Flake/Scrap Dehumidifier Crystallizer, the Infrared crystal dryer PET Granulation, and the PA Dryer. LIANDA MACHINERY is looking forward to hearing from you and serving your needs.

Post time: Feb-19-2024