OEM Customized Dessicant Dryer/Dehumidifier - PETG Dryer/Infrared Rotary Dryer/Plastic Dehumidifier/Plastic resin dryer – LIANDA

OEM Customized Dessicant Dryer/Dehumidifier - PETG Dryer/Infrared Rotary Dryer/Plastic Dehumidifier/Plastic resin dryer – LIANDA Detail:

Application Sample

| Raw Material | PETG (K2012 )SK Chemical |   |

| Using Machine | LDHW-1200*1000 |  |

| Initial moisture | 550ppmTested by German Sartorius Moisture test instrument |  |

| Drying Temperature set | 105℃ | |

| Drying time set | 20mins | |

| Final moisture | 20ppmTested by German Sartorius Moisture test instrument |  |

| Final product | Dried PETG no clumping, no pellets sticking |  |

How to Work

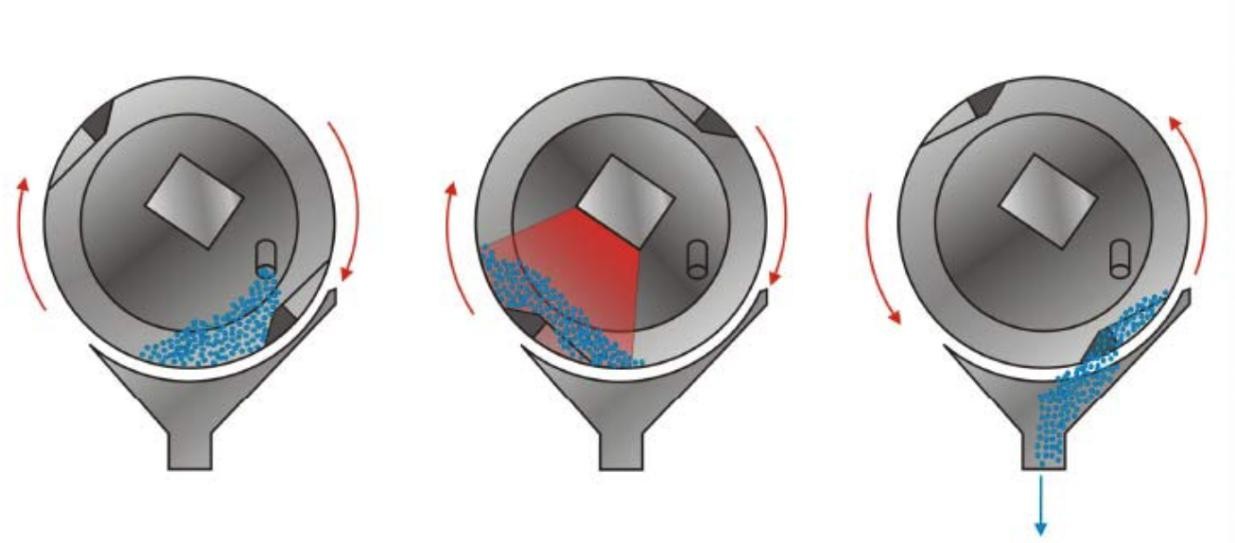

>>At first step, the only target is to heat up the material to a preset temperature.

Adopt relatively slow speed of drum rotating, the Infrared lamps power of the dryer will be at a higher level, then the PETG pellets will have a fast heating till the temperature rises to the preset temperature.

>>Drying step

Once the material gets to the temperature, the speed of the drum will be increased to a much higher rotating speed to avoid the clumping of the material. At the same time, the infrared lamps power will be increased again to finish the drying. Then the drum rotating speed will be slowed down again. Normally the drying process will be finished after 15-20mins. (The exact time depends on the property of material)

>>After finishing the drying processing, the IR Drum will automatically discharge the material and refill the drum for the next cycle.

The automatic refilling as well as all relevant parameters for the different temperature ramps is fully integrated in the state-of-the-art Touch Screen control. Once parameters and temperature profiles are found for a specific material, theses settings can be saved as recipes in the control system.

Machine Photos

Material Free Testing

Our factory has build Test Center. In our Test center, we can perform continuous or discontinuous experiments for customer’s sample material. Our equipment is furnished with comprehensive automation and measurement technology.

• We can demonstrate — Conveying/Loading, Drying& Crystallization, Discharging.

• Drying and crystallization of material to determine residual moisture, residence time, energy input and material properties.

• We can also demonstrate performance by subcontracting for smaller batches.

• In accordance with your material and production requirements, we can map out a plan with you.

Experienced engineer will make the test. Your employees are cordially invited to participate in our joint trails. Thus you have both the possibility to contribute actively and the opportunity to actually see our products in operation.

Machine Installation

>> Supply Experienced engineer to your factory to help installation and material test running

>> Adopt aviation plug, no need to connect the electrical wire while the customer get the machine in his factory. To simplify the installation step

>> Supply the operation video for installation and running guide

>>Support on line service

Product detail pictures:

Related Product Guide:

Adhering for the theory of "quality, services, performance and growth", we have received trusts and praises from domestic and worldwide shopper for OEM Customized Dessicant Dryer/Dehumidifier - PETG Dryer/Infrared Rotary Dryer/Plastic Dehumidifier/Plastic resin dryer – LIANDA, The product will supply to all over the world, such as: Thailand, Washington, Jamaica, Our Company has professional engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the products, Please feel free to contact us.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!