OEM Factory for Infrared Rotary Drum Dryer System - PET Resin Dryer/Infrared Rotary Dryer/Plastic Desiccant Dehumidifier/Plastic dryer/APET Dryer – LIANDA

OEM Factory for Infrared Rotary Drum Dryer System - PET Resin Dryer/Infrared Rotary Dryer/Plastic Desiccant Dehumidifier/Plastic dryer/APET Dryer – LIANDA Detail:

Application Sample

| Raw Material | PET Resin CR-BrightFor food package |  |

| Using Machine | LDHW-600*1000 |  |

| Initial moisture | 2210ppmTested by German Sartorius Moisture test instrument |  |

| Drying Temperature set | 200℃ | |

| Drying time set | 20mins | |

| Final moisture | 20ppmTested by German Sartorius Moisture test instrument |  |

| Final product | Dried PET Resin no clumping, no pellets sticking |  |

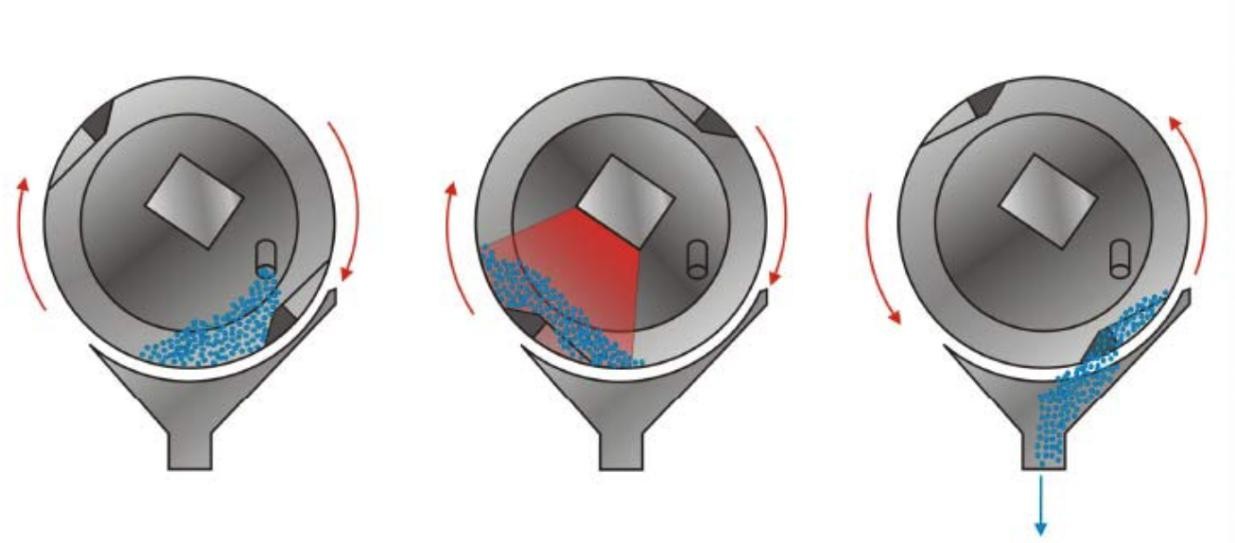

How to Work

>>At first step, the only target is to heat up the material to a preset temperature.

Adopt relatively slow speed of drum rotating, the Infrared lamps power of the dryer will be at a higher level, then the PET pellets will have a fast heating till the temperature rises to the preset temperature.

>>Drying step

Once the material gets to the temperature, the speed of the drum will be increased to a much higher rotating speed to avoid the clumping of the material. At the same time, the infrared lamps power will be increased again to finish the drying. Then the drum rotating speed will be slowed down again. Normally the drying process will be finished after 15-20mins. (The exact time depends on the property of material)

>>After finishing the drying processing, the IR Drum will automatically discharge the material and refill the drum for the next cycle.

The automatic refilling as well as all relevant parameters for the different temperature ramps is fully integrated in the state-of-the-art Touch Screen control. Once parameters and temperature profiles are found for a specific material, theses settings can be saved as recipes in the control system.

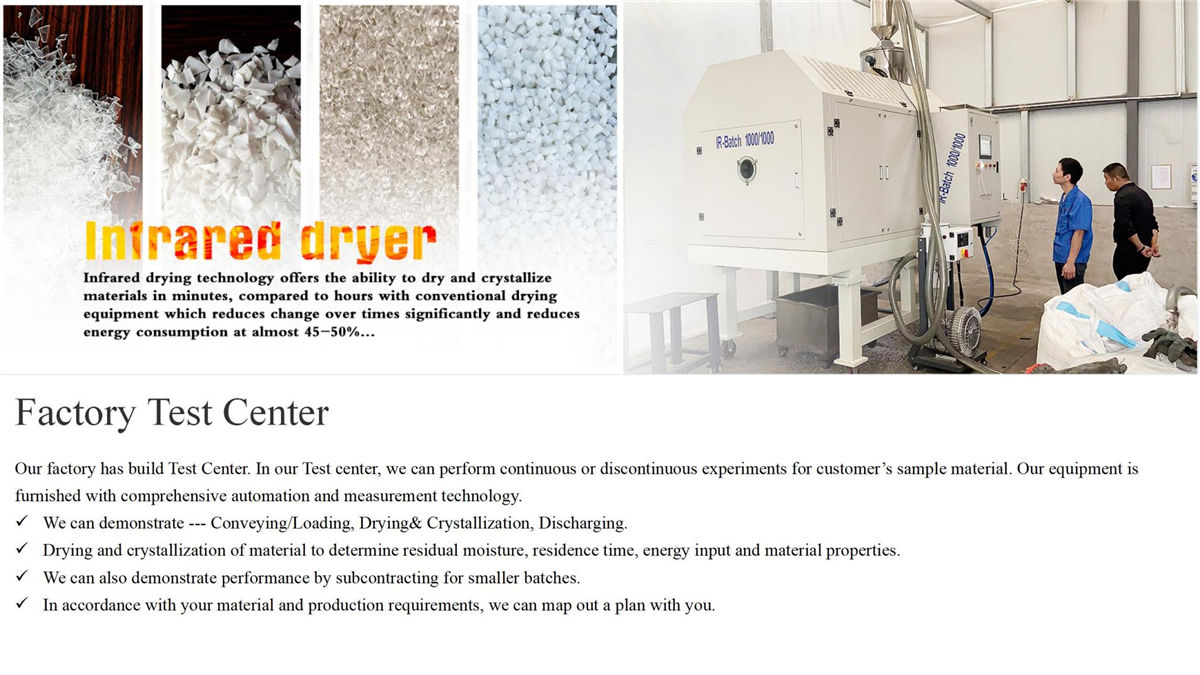

Our Advantage

| 1 | Low energy consumption | Significantly lower energy consumption compared to conventional processes, through the direct introduction of infrared energy to the product | |

| 2 | Minutes instead of hours | The product remains for only a few minutes in the drying process and is then available for further production steps. | |

| 3 | Instantly | The production run can start immediately upon startup. A warm-up phase of the machine is not required. | |

| 4 | Gently | The material is heated gently from the inside to the outside and not loaded from the outside for hours with heat, and thereby possibly damaged. | |

| 5 | In one step | Crystallization and drying in one step | |

| 6 | Increased throughput | Increase of plant throughput by means of reduced load on extruder | |

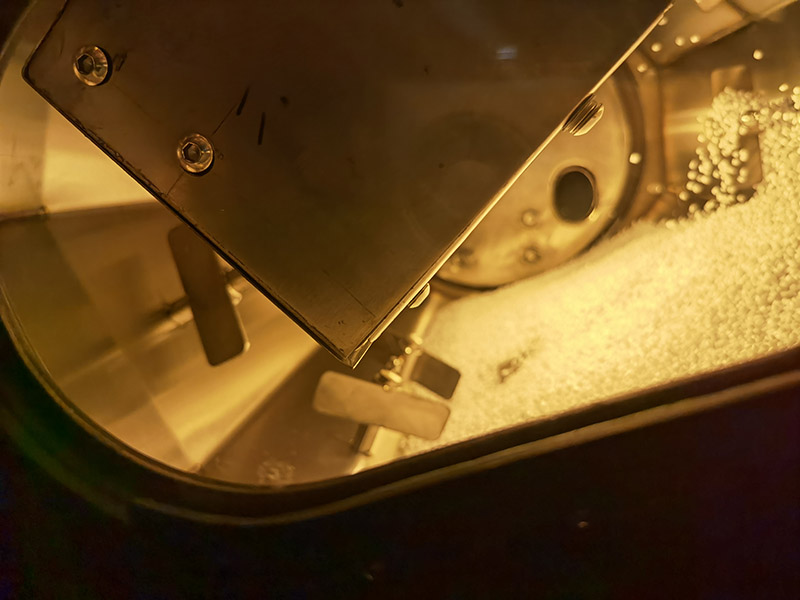

| 7 | No clumping, no sticking | The rotation of the drum ensures constant movement of the material.The spiral coils and mixing elements designed for your product ensure an optimal mix of material and avoids clumping. The product is evenly heated | |

| 8 | Siemens PLC control | Control.The process data, such as material and exhaust air temperature or fill levels are continuously monitored by means of sensors and pyrometers. Deviations trigger automatic adjustment.Reproducibility.Recipes and process parameters can be stored in the controlling system to ensure optimal and reproducible results.Remote maintenance.Online service via modem. | |

| 9 | Drying time only needs 20mins, final moisture can be ≤ 30ppm | The infrared rays that penetrate and reflect from the material do not affect the organization of the material, but the absorbed tissue will be converted into heat energy due to molecular excitation, which causes the temperature of the material to rise. | |

| 10 | No clumping, no sticking | The rotation of the drum ensures constant movement of the material.The spiral coils and mixing elements designed for your product ensure an optimal mix of material and avoids clumping. The product is evenly heated | |

| 11 | Easy clean and change material | Good access to all components allows for easy and fast cleaning.Rapid product change-over. | |

Machine Photos

Machine Application

Drying Drying of plastic granulates ( PET,TPE, PETG, APET, RPET, PBT, ABS/PC, HDPE, LCP, PC,PP , PVB,WPC,TPU etc) as well as other free-flowing bulk materials

Crystallization PET (Bottle flakesm granulates, sheet scrap), PET Masterbatch, CO-PET, PBT,PEEK, PLA, PPS etc

Diverse Thermal processed for removal of rest oligomeren and volatile components

Material Free Testing

Experienced engineer will make the test. Your employees are cordially invited to participate in our joint trails. Thus you have both the possibility to contribute actively and the opportunity to actually see our products in operation.

Machine Installation

>> Supply Experienced engineer to your factory to help installation and material test running

>> Adopt aviation plug, no need to connect the electrical wire while the customer get the machine in his factory. To simplify the installation step

>> Supply the operation video for installation and running guide

>>Support on line service

Product detail pictures:

Related Product Guide:

With this motto in mind, we have become one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for OEM Factory for Infrared Rotary Drum Dryer System - PET Resin Dryer/Infrared Rotary Dryer/Plastic Desiccant Dehumidifier/Plastic dryer/APET Dryer – LIANDA, The product will supply to all over the world, such as: UK, Ethiopia, Frankfurt, Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, please do not hesitate to contact us.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!