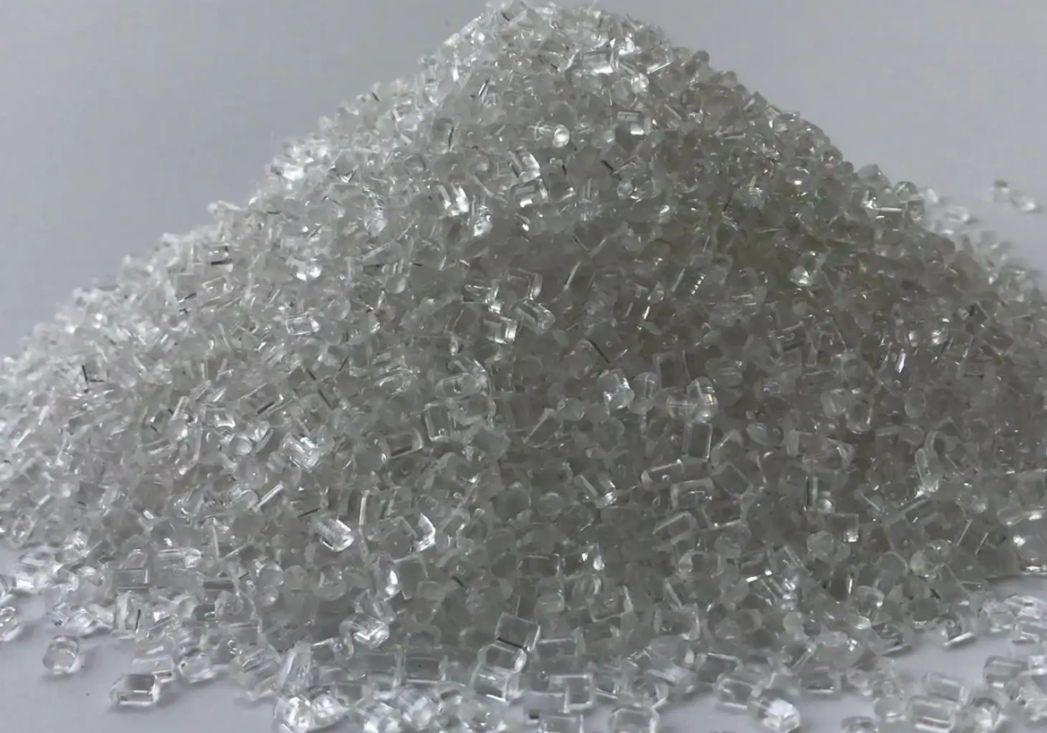

PET Granulating line

Infrared Crystallization Dryer for rPET Extrusion granulating line

Infrared Pre-Drying of rPET Bottle Flakes: Increasing Output and Improving Quality on PET Extruders

Drying is the single most important variable in the processing.

>>Improving the manufacturing and physical properties of recycled, food-grade PET through technology powered by infrared light has a crucial part to play in the intrinsic viscosity (IV) property

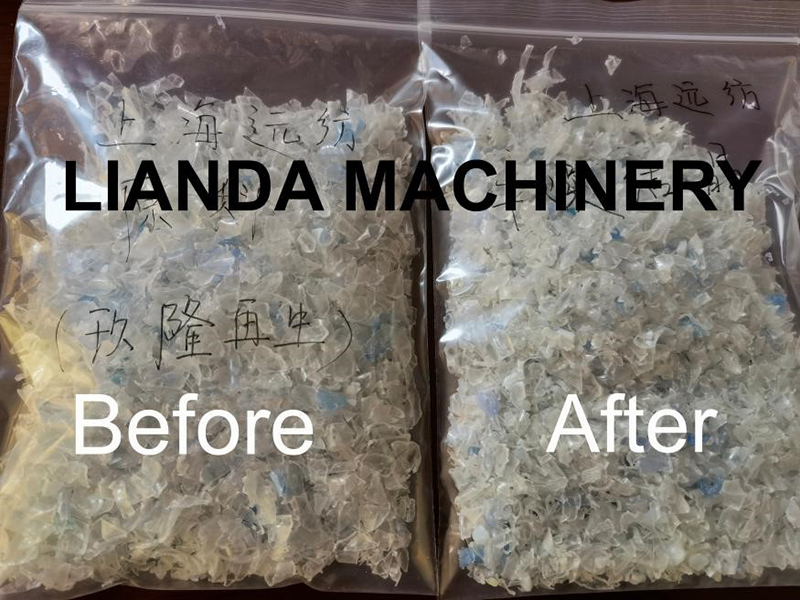

>>Pre-crystallization &drying of the flakes prior to extrusion helps minimize the loss of IV from PET, a critical factor for reuse of the resin

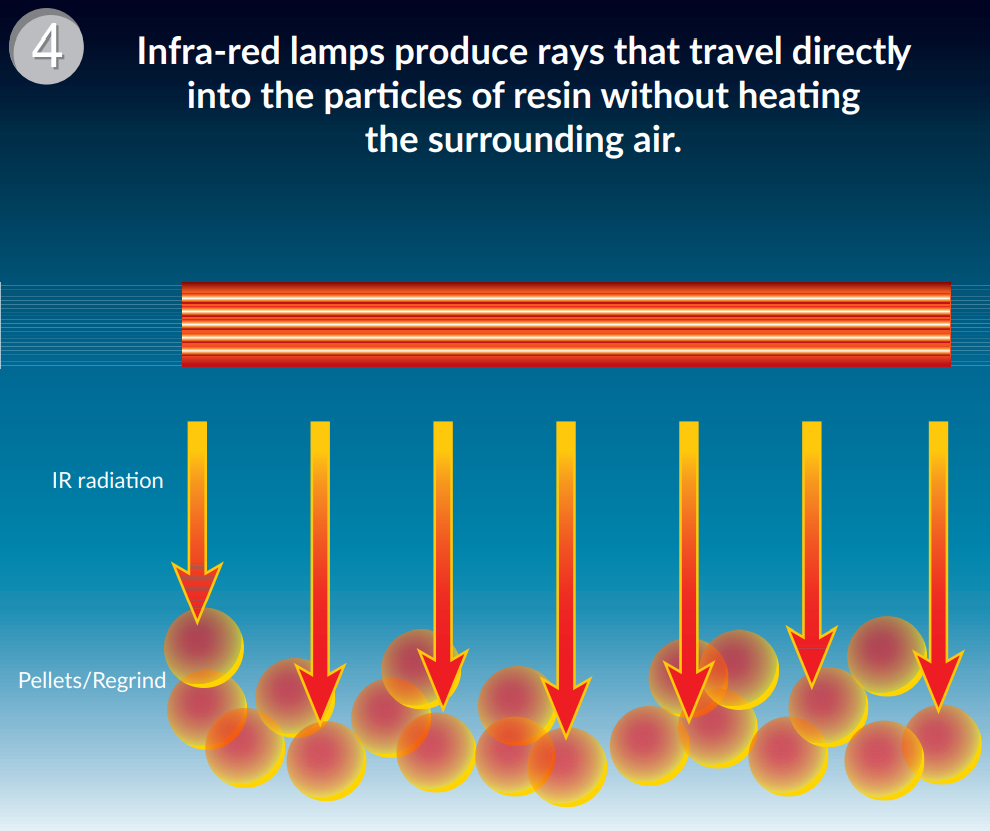

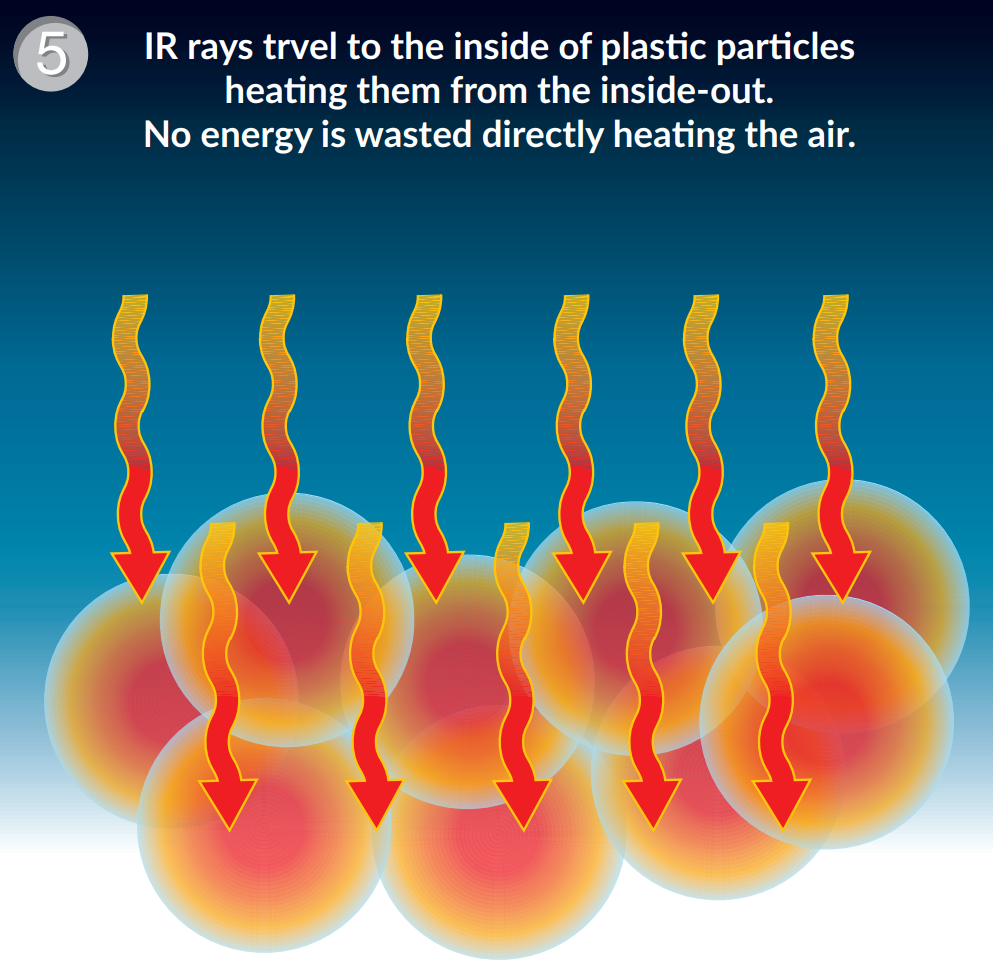

>>Reprocessing the flakes in the extruder reduces IV due to hydrolysis i the presence of water, and that’s why pre-drying to a homogeneous drying level with our IRD System can limit this reduction. In addtion, the PET melt strips does not turn yellow because drying time is reduced ( Drying time only needs 15-20mins, final moisture can be ≤ 30ppm, energy consumption less than 80W/KG/H)

>>Shearing in the extruder is thereby also reduced because the preheated material enters the extruder at constant temperature”

>>Improving the output of PET Extruder

An increase of the bulk density by 10 to 20 % can be achieved in the IRD, improves the feed performance at the extruder inlet substantially – while the extruder speed remains unchanged, there is a substantially improved filling performance on the screw.

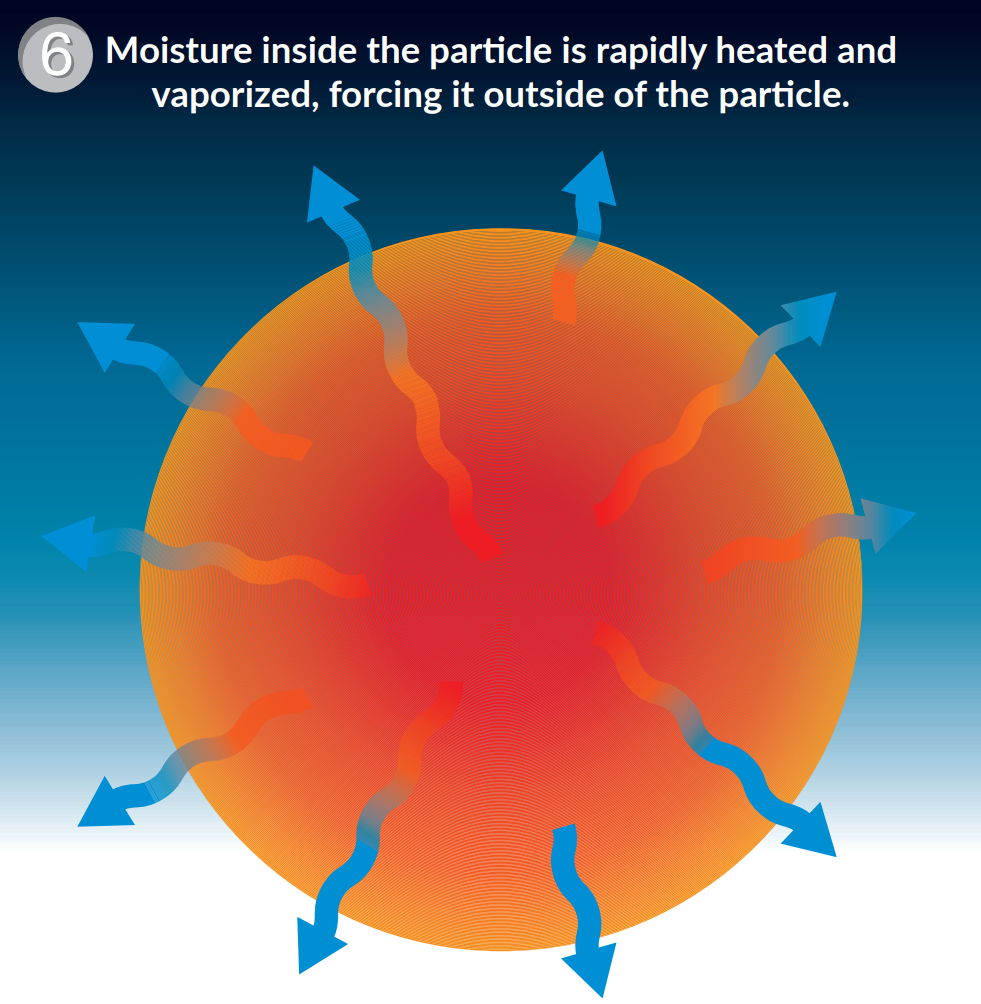

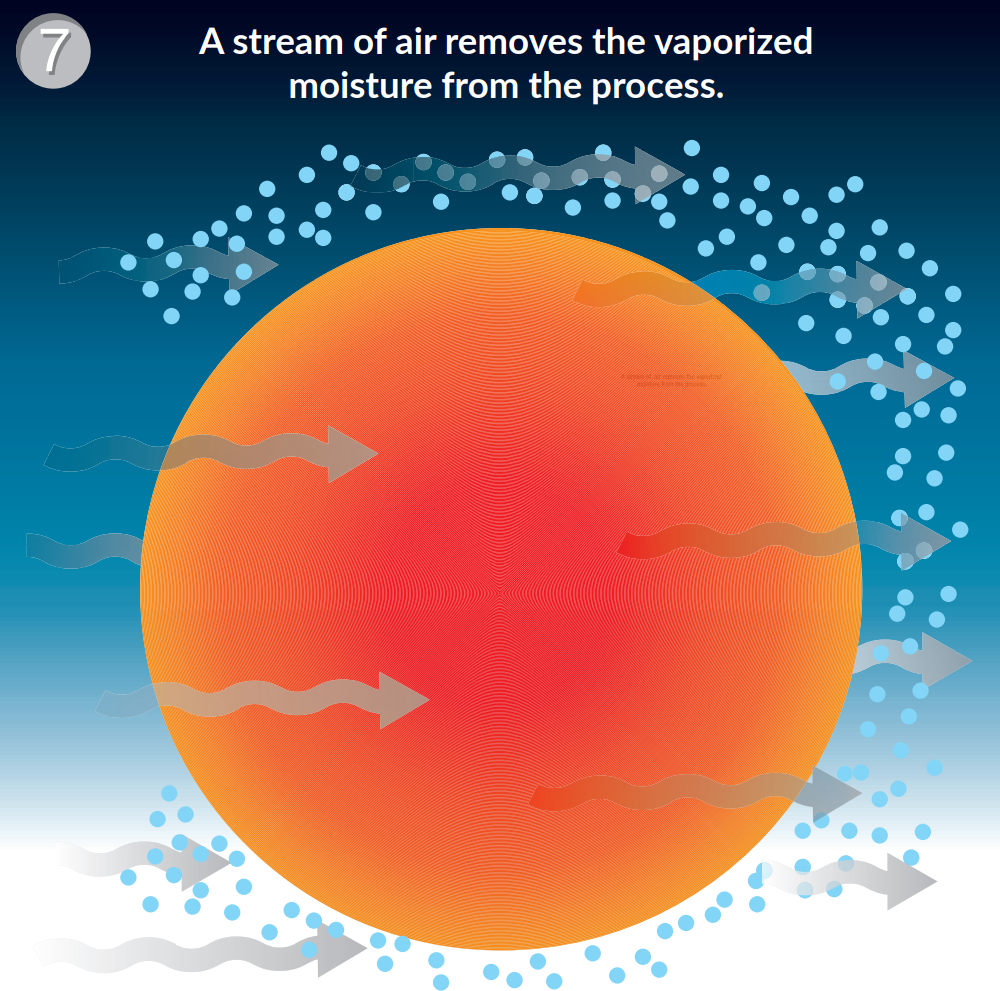

Working Principle

Advantage we Make

※ Limiting the hydrolytic degradation of the viscosity.

※ Prevent increasing AA levels for materials with food contact

※ Increasing the capacity of the production line up to 50%

※ Improvement and make the product quality stable-- Equal and repeatable input moisture content of the material

→ Reduce manufacture cost of PET pellets: Up to 60% less energy consumption than conventional drying system

→ Instant start-up and quicker shut down --- No need pre-heating

→ Drying& crystallization will be processed in one step

→ The machine line is equipped with Siemens PLC system with one key memory function

→ Covers an area of small, simple structure and easy to operate and maintenance

→ Independent temperature and drying time set

→ No segregation of products with different bulk densities

→ Easy clean and change material

Machine Running in Customers' factory

FAQ

Q: What’s the final moisture you can get ? Do you have any limitation on initial moisture of the raw material ?

A: The final moisture we can get ≤30ppm (Take PET as example). Initial moisture can be 6000-15000ppm.

Q: We use Double parallel screw extruding with vacuum degassing system for PET Extrusion granulating line, shall we still need to use pre-dryer?

A: We suggest to use Pre-dryer before extrusion. Usually such system has the strict requirement on initial moisture of PET material. As we know PET is kind of material which can absorb the moisture from atmosphere which will cause the extrusion line working badly. So we suggest to use pre-dryer before your extrusion system:

>>Limiting the hydrolytic degradation of the viscosity

>>Prevent increasing AA levels for materials with food contact

>>Increasing the capacity of the production line up to 50%

>>Improvement and make the product quality stable-- Equal and repeatable input moisture content of the material

Q: What’s the delivery time of your IRD?

A: 40 working days since we get your deposit in our company account.

Q: How about the installation of your IRD?

Experienced engineer can help installation the IRD system for you in your factory. Or we can supply guide service on line. The whole machine adopt aviation plug, easier for connection.

Q: What’s the IRD can be applied for ?

A: It can be pre-dryer for

- PET/PLA/TPE Sheet extrusion machine line

- PET Bale strap making machine line

- PET masterbatch crystallization and drying

- PETG Sheet extrusion line

- PET monofilament machine, PET monofilament extrusion line,PET monofilament for broom

- PLA /PET Film making machine

- PBT, ABS/PC, HDPE, LCP, PC, PP, PVB, WPC, TPE, TPU, PET (Bottleflakes, granules, flakes), PET masterbatch, CO-PET, PBT, PEEK, PLA,PBAT, PPS etc.

- Thermal processes for the removal of rest oligomeren and volatile components.