Infrared Rotary Dryer yePET Fiber kugadzira

Product Details

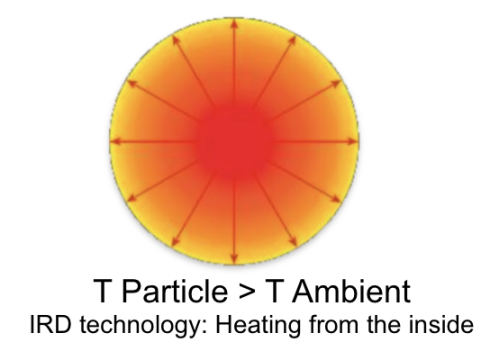

Iro infrared rays inopinda uye inoratidzira kubva kune iyo zvinhu haikanganisi kurongeka kwezvinhu, asi iyo yakabatwa tishu inoshandurwa kuita kupisa kwesimba nekuda kweiyo molecular excitation, izvo zvinoita kuti kupisa kwechinhu kusimuke nekukurumidza.

Kupisa kusvika pakati. Kuburikidza nepfupi-wave infrared light zvinhu zvinodziya zvakananga kubva mukati

Kubva Mukati kusvika kunze. Simba riri mukati rinopisa zvinhu kubva ku

mukati kunze, saka mwando unodzingwa kubva mukati kuenda kunze kwechinhu .

Evaporation yekunyorova.Iyo yakawedzera kutenderera kwemhepo mukati memuomesi inobvisa hunyoro hwakaputika kubva muchinhu.

Nyaya Yokudzidza

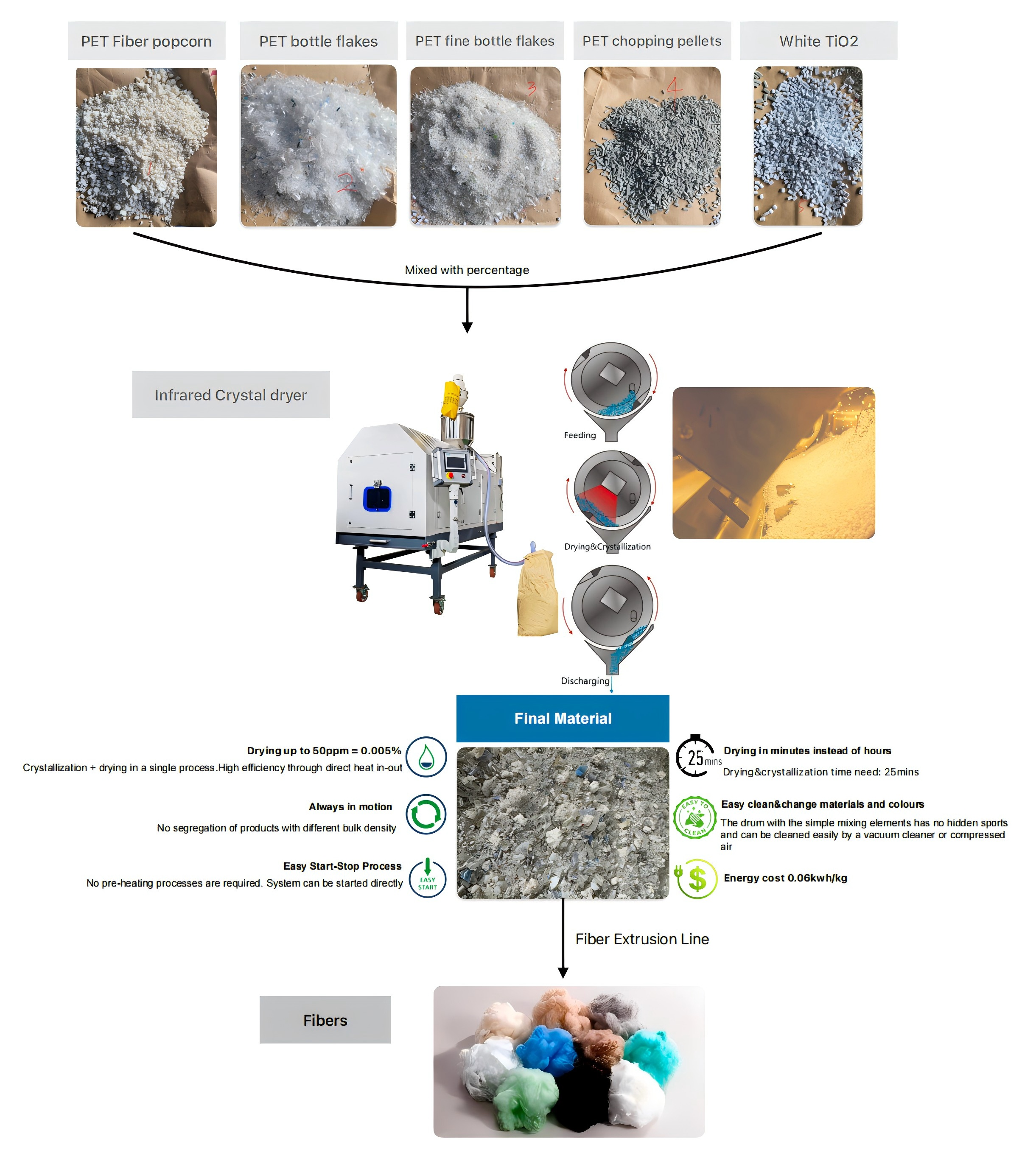

Processing yaratidzwa

Advantage zvatinogadzira mukugadzirisa

①Kutanga nekukasira kuvhara

→Kukurumidza kutanga kwekumhanya kwekugadzira kunogoneka.Kudziya-up chikamu chemuchina hachidiwe

→Kugadzirisa kunogona kutangwa, kumiswa uye kutangwazve nyore

② Nguva dzose ichifamba

→ Hapana kupatsanurwa kwezvigadzirwa zvine huwandu hwakasiyana huwandu

→Kutenderera kwedhiramu kunoita kuti zvinhu zvirambe zvichifamba uye kuungana kunogona kudzivirirwa

③ Kuomesa mumaminitsi panzvimbo yemaawa (Kuomesa & crystallization nguva inoda: 25mins)

→Mwaranzi yeInfrared yakakonzera ma molecular thermal pscillations ayo anoita zvakananga papakati pezvikamu kubva mukati kunze. kuitira kuti hunyoro huri mukati mezvidimbu huchimbidze kupisa uye huputike mumhepo inotenderera inotenderera, uye hunyoro hunobviswa panguva imwe chete.

④ Kuvandudza kubuda kwePET Extruder

→ Kuwedzera kwehuwandu hwehuwandu ne10-20% inogona kuwanikwa muIRD system, kuvandudza kusimba kwekudya pane extruder inlet zvakanyanya, nepo extruder yekumhanyisa inoramba isina kuchinjika, pane yakagadziridzwa kuzadza kuita pane screw.

⑤ Zviri nyore kuchenesa & shandura zvinhu uye mavara

→ Iyo ngoma ine zviri nyore kusanganisa zvinhu haina mitambo yakavanzika uye inogona kucheneswa zviri nyore neavacuum cleaner kana mhepo yakamanikidzwa.

⑥ Energy mutengo 0.06kwh/kg

→ nguva pfupi dzekugara = high process flexiblility

→ simba rimwechete rinogadziriswa --- Mwenje wega wega unogona kudzorwa nePLC chirongwa

FAQ

a.Ndeipi inogumira pakunyorova kwekutanga kwezvakagadzirwa?

→ Hapana kuganhurirwa chaiko pakunyorova kwekutanga, 2%,4% zvese zvakanaka

b. Ndeupi hunyoro hwekupedzisira hunogona kuwana mushure mekuomeswa?

→ ≦30ppm

c.Chii chiri kuomesa & crystallization nguva inoda?

→ 25-30mins. Iko kuomesa & crystallized kuchapedzwa mune imwe nhanho

d.Kunobva kupi? Kuderera kwedova mhepo yakaoma?

→ Isu tinotora marambi e infrared (infrared wave) senzvimbo yekudziya.Nechiedza chepfupi-wave infrared light material inodziya yakananga kubva mukati kuenda kunze. Simba riri mukati rinopisa zvinhu kubva mukati zvichienda kunze, saka hunyoro hunodzingwa kubva mukati kuenda kunze kwechinhu.

e. Ko iyo yakasiyana density zvinhu ichave yakaturikidzana inosimbisa kuomeswa kwekugadzirisa?

→ Kutenderedzwa kwedhiramu kunoita kuti zvinhu zvirambe zvichifamba,--Hapana kupatsanurwa kwezvinhu zvine huremu hwakasiyana uchipihwa kune extruder.

f. Kuomesa tembiricha kwakadini?

→ Iyo yekuomesa tembiricha seti chiyero: 25-300 ℃. SePET, isu tinokurudzira kutora anenge 160-180 ℃

g. Zviri nyore here kushandura colorbatch?

→Ngoma ine zviri nyore kusanganisa zvinhu haina mitambo yakavanzika, kushandura zviri nyore zvinhu kana ruvara materbatch

h.Unoita sei nehupfu?

→ Isu tine guruva rinobvisa iro richashanda neIRD pamwechete

I. Chii chiri kumuka kwemarambi?

→ 5000-7000hours. (Hazvireve kuti mwenje haichashande, kungodzikisira simba

J. Ndeipi nguva yekutumira?

→ 40 mazuva ekushanda mushure mekuwana dhipoziti

kana uine mamwe mashoko aunoda kuziva, tapota titumire E-mail:

Kumhanya mucustomer factory reference

Basa redu

Fekitori yedu ine kuvaka Test Center. Munzvimbo yedu yeTest, tinogona kuita zviyedzo zvinoenderera kana zvisingaendereki kune zvemutengi sampuli zvinhu. Midziyo yedu inopihwa yakazara otomatiki uye kuyerwa tekinoroji.

- Tinogona kuratidza --- Kutakura / Kurodha, Kuomesa & Crystallization, Kuburitsa.

- Kuomesa uye crystallization yezvinhu kuti uone zvakasara mwando, nguva yekugara, simba rekuisa uye zvinhu zvenyama.

- Isu tinogona zvakare kuratidza kuita nekuita subcontracting kune mabhechi madiki.

- Zvinoenderana nezvako zvekushandisa uye zvekugadzira zvinodiwa, isu tinokwanisa mepu kuronga newe.

Injiniya ane ruzivo achaita bvunzo. Vashandi vako vanokokwa neushamwari kuti vatore chikamu mumakwara edu akabatana. Saka iwe une zvese mukana wekupa nesimba uye mukana wekuona chaizvo zvigadzirwa zvedu zviri kushanda.