PA Dryer

Infrared Crystallization Dryer yePA Pellets

Mhinduro dzePA Pellets/Granulates

Kuomesa ndiyo imwechete yakakosha shanduko mukugadzirisa.

LIANDA yanga ichishanda pamwe chete nevanopa resin uye processors kugadzira michina uye maitiro anogona kubvisa hunyoro-ane chekuita nehunyoro nyaya uchichengetedza simba zvakare.

>> Adopt Rotation drying system kuchengetedza yunifomu yakaoma

>> Kusanganiswa kwakanaka pasina tsvimbo kana kubatira panguva yekuomesa

>> Kushandisa Simba

Nhasi, vashandisi veLIANDA IRD vari kuzivisa mutengo wesimba se 0.06kwh/kg, pasina kupira mhando yechigadzirwa.

>> Yakazara maitiro ekuonekwa ayo iyo IRD system PLC inodzora inoita kuti igoneke

>>Kuti uwane 50ppm chete IRD inokwana ne20mins Kuomesa & crystallization mune imwe nhanho.

>>Zvakawanda application

Mutengi Factory Test

Kunyorova kwekutanga: 4500PPM

| Mutengi Uripo midziyo: Fluidized bed dryer (Horizontal Style) | Iye zvino LIANDA Ird | |

| Kuomesa tembiricha | 130 ℃ | 120 ℃ |

| Kuona tembiricha | Kupisa kwemhepo inopisa | Zvakananga zvinhu tembiricha |

| Kuomesa nguva | Kunenge 4-6hours | 15-20mins |

| Kunyorova kwekupedzisira | ≤1000ppm | ≤100ppm |

| Melt mitsetse | ||

| Color | Zviri nyore kuve yero

| Zvichiri pachena

|

| Kudiwa kwemidziyo yekubatsira | Zvimwe zvekushandisa zvekubatsira senge mafeni, maheater, vapatsanuri, kana vaunganidzi veguruva zvinodiwa, izvo zvakakura uye zvinogara nzvimbo yakakura. | Hapana |

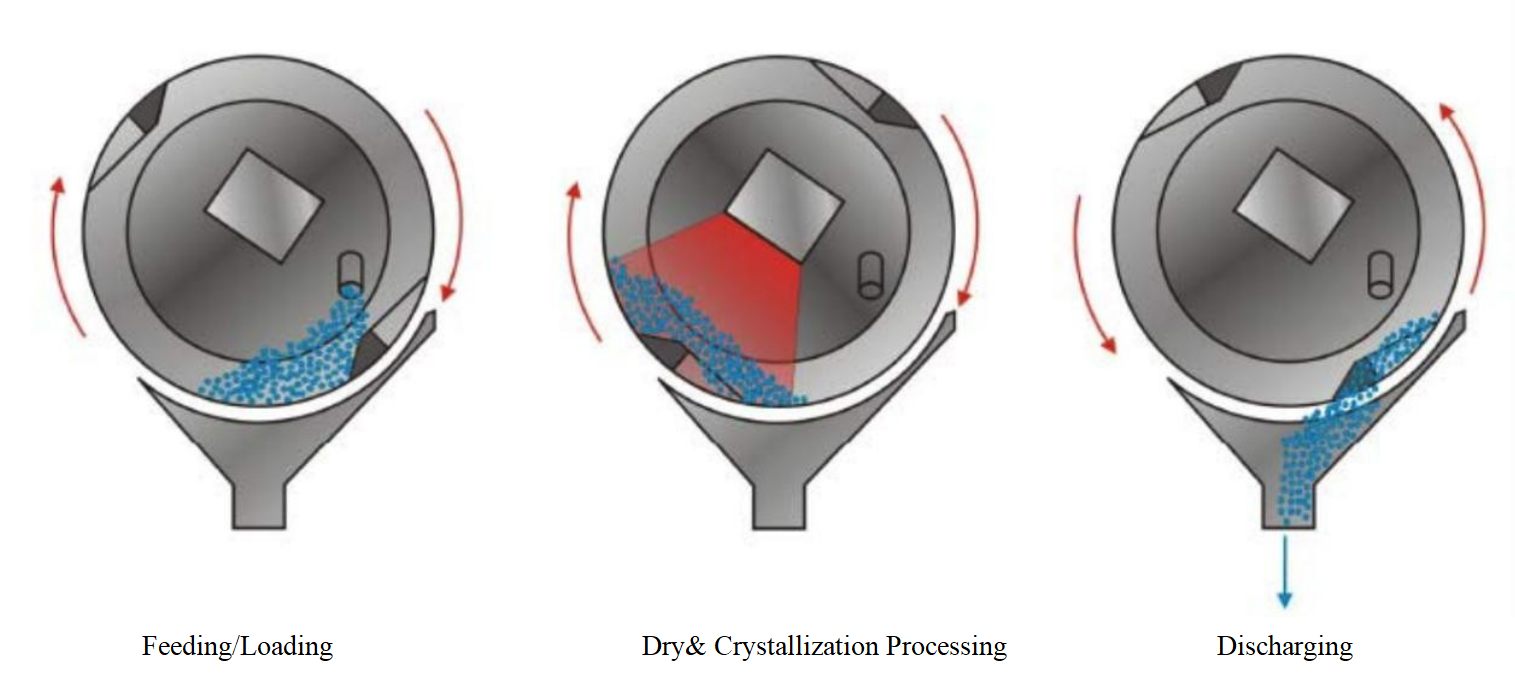

Mashandiro

>> Pakutanga nhanho, chinangwa chega ndechekupisa zvinhu kusvika kune tembiricha yakatarwa.

Adopt inononoka kumhanya yedhiramu inotenderera, iyo Infrared mwenje simba remuomese ichange iri padanho repamusoro, ipapo resin yepurasitiki ichave nekudziya nekukurumidza kusvika tembiricha yakwira kusvika kune preset tembiricha.

>> Kuomesa & Crystallizing nhanho

Kana zvinhu zvasvika patembiricha, kumhanya kwedhiramu kunowedzerwa kusvika padanho repamusoro rekutenderera kudzivirira kuungana kwezvinhu. Panguva imwecheteyo, iyo infrared mwenje simba inowedzerwa zvakare kupedzisa kuomesa & crystallization. Ipapo ngoma inotenderera sipidhi inodzikiswa zvakare. Kazhinji kuomesa & crystallization maitiro anozopedzwa mushure me15-20mins. (Nguva chaiyo inoenderana nepfuma yezvinhu)

>> Mushure mekupedza kuomesa & kristalllization kugadzirisa, iyo IR Drum inozoburitsa otomatiki zvinhu uye kuzadza chigubhu kune inotevera kutenderera.

Kuzadza otomatiki pamwe chete nematanho ese akakodzera eakasiyana tembiricha ramps akanyatsobatanidzwa mune iyo-ye-iyo-iyo-inoyevedza Touch Screen control. Kamwe maparamita uye tembiricha profiles zvawanikwa zvechimwe chinhu, zvigadziriso zvemaseti zvinogona kuchengetwa semabikirwo muhurongwa hwekutonga.

Advantage We Make

- Kusvika ku60% kushoma kushandiswa kwesimba pane kwakajairika kuomesa system

- Instant-up uye nekukurumidza kuvhara

- Hapana kupatsanurwa kwezvinhu zvine huwandu hwakasiyana densities

- Uniform drying

- Kuzvimiririra tembiricha uye kuomesa nguva yakatarwa

- Hapana pellets inobatana & tsvimbo

- Easy yakachena uye shandura zvinhu

- Kunyatsorapwa zvinhu

Machine Kumhanya mufekitari yeVatengi

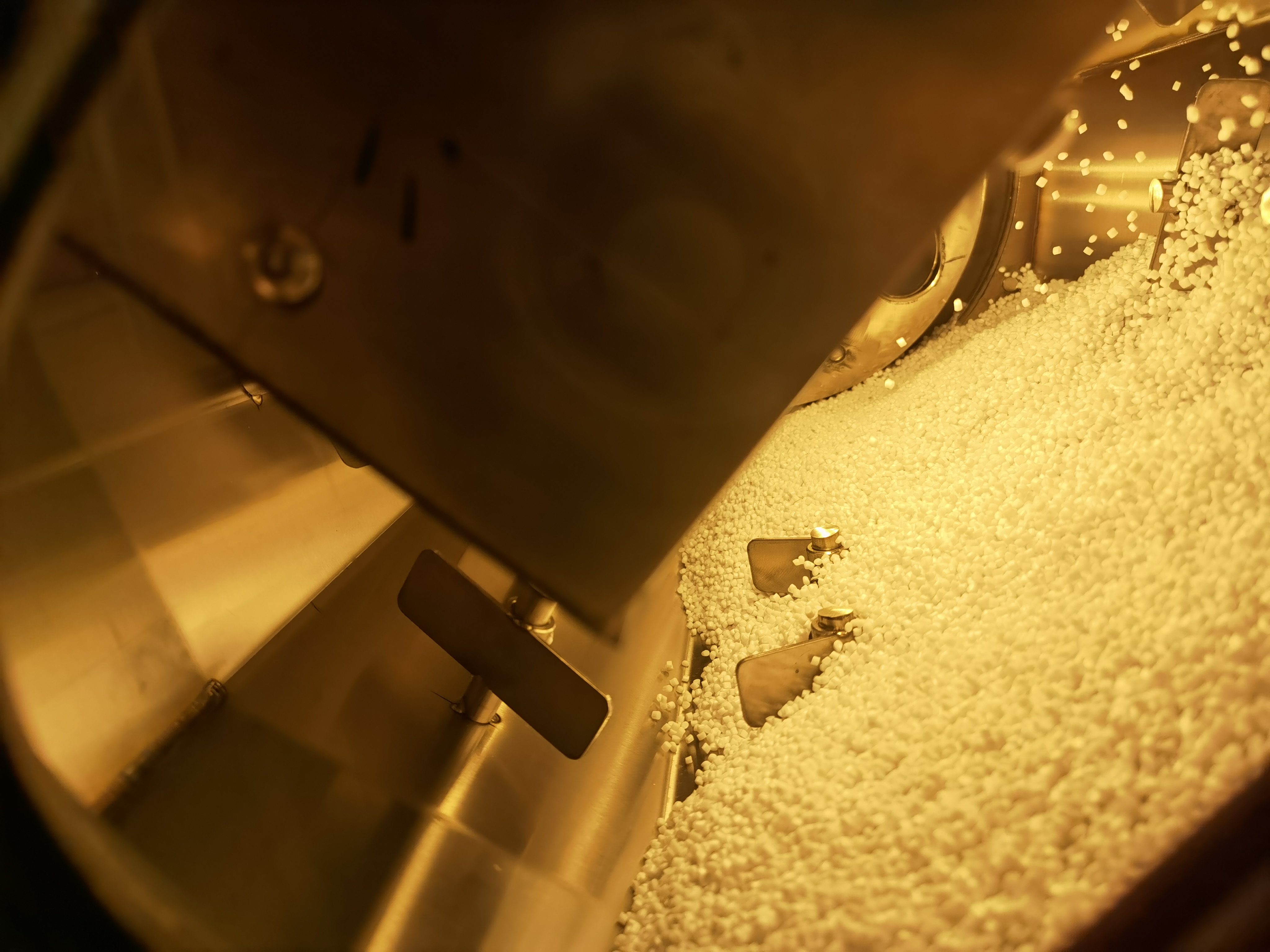

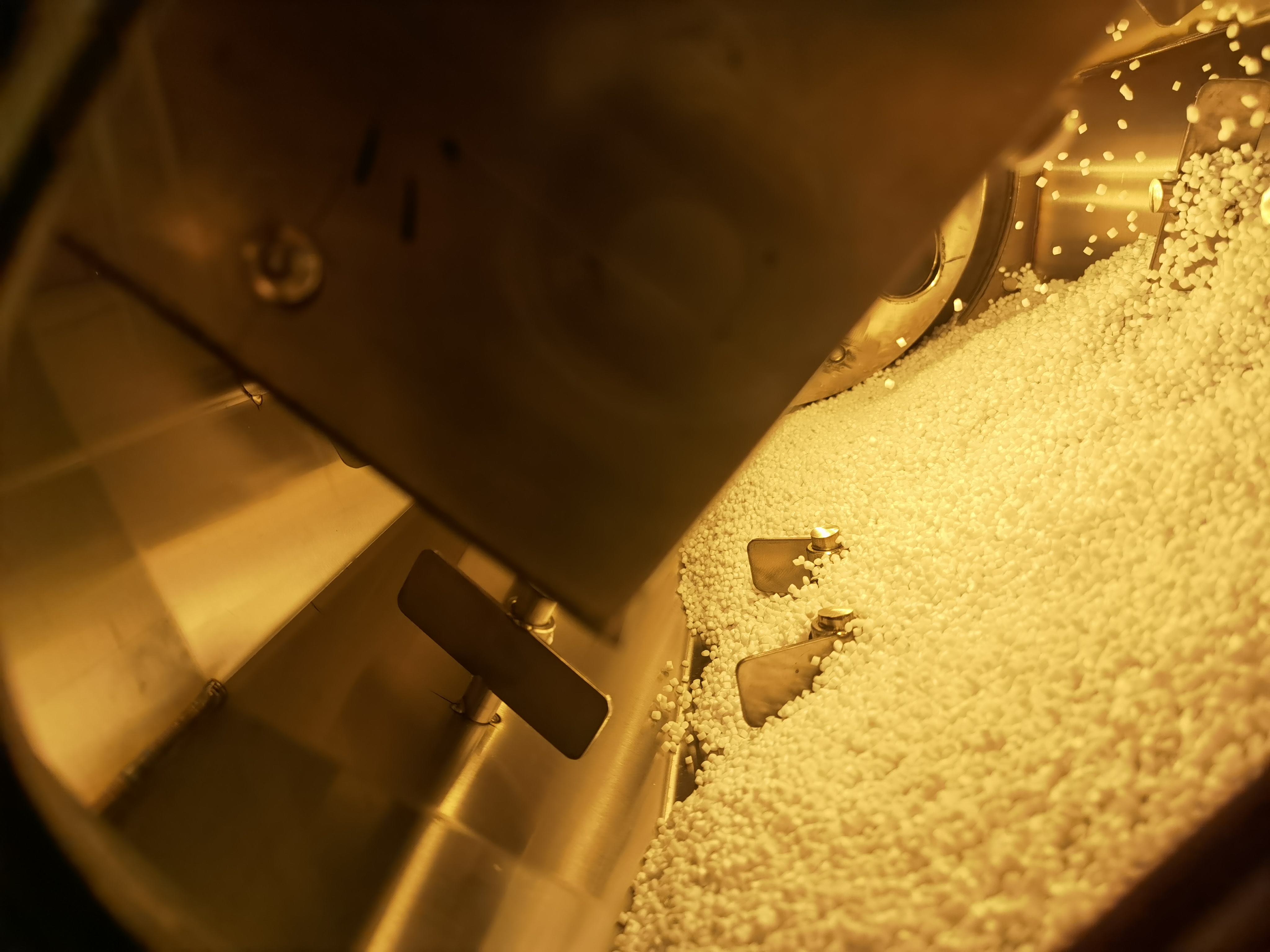

Machine photos