PET Bottle Flake Granulation Line

PET Bhodhoro Recycling Pelletizer PET Granulation Machine Process kuyerera

Kutsanangurwa Kwehunyanzvi

|

Machine Name |

PET Single Screw Extrusion pelletizing Line |

|

Raw Material |

rPET Flakes |

|

Final Product |

rPET Pellets |

|

Production Line zvikamu | Infrared crystal dryer system: Vacuum feeder/ Infrared crystal dryer/ Vacuum discharger

Single Screw Extrusion granulating line: Single screw main extruder/Hydraulic Double Pistons screen changer/Die musoro/Inokwesha mvura dhiri/Inotsvaira pellitizer/Vertical dewatering machine/Vibrating sieve machine/ Kuchengeta

|

|

Screw dhayamita |

90mm-150mm |

|

L/D |

1:24/1:30 |

|

Output range |

150-1000KG/H |

|

Screw material |

38CrMoAlA neNitrding Treatment |

|

Pelletizing Type |

Kuyerera kwemvura & pelletizing |

|

Skirini shanduko |

Hydraulic Double Pistons Screen Changer |

Machine Details

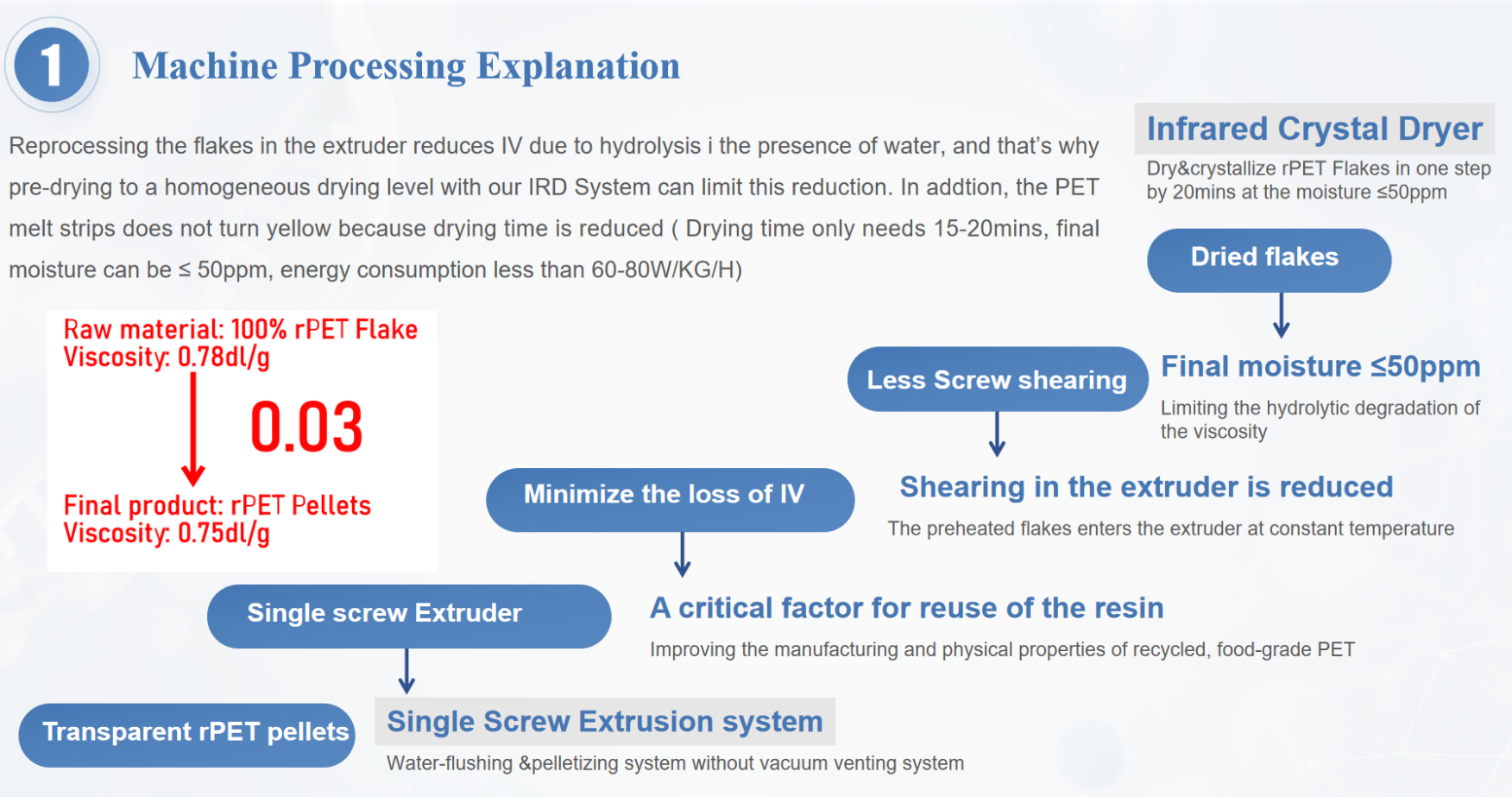

Infrared Crystal Dryer (LIANDA PATENT DESIGN)

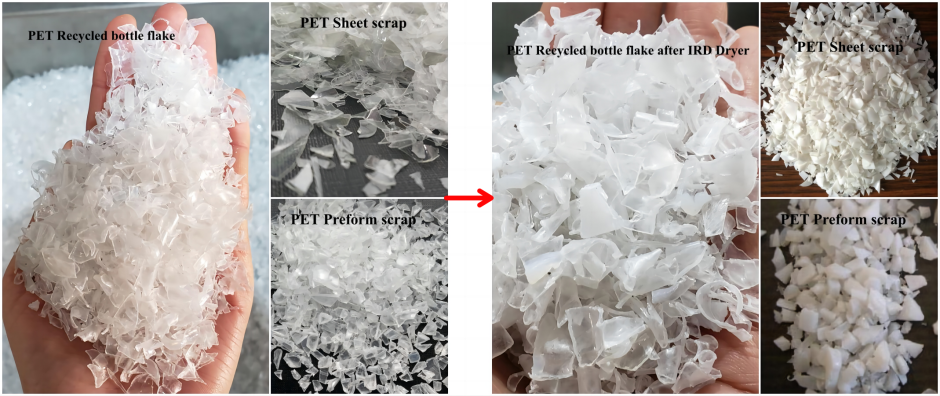

①Kuvandudza kugadzirwa uye zvemuviri zvimiro zvezvekudzokororwa, chikafu-giredhi PET kuburikidza tekinoroji inofambiswa neinfrared wave ine chikamu chakakosha kuita mumukati viscosity (IV) pfuma.

②Pre-crystallization & kuomeswa kwemaflakes kusati kwaitwa extrusion kunobatsira kuderedza kurasikirwa kweIV kubva kuPET, chinhu chakakosha chekushandisa zvakare resin.

③Kugadziridzazve maflakes ari muextruder kunoderedza IV nekuda kwehydrolysis pamberi pemvura, ndosaka kufanoomesa kusvika kune homogeneous yekuomesa nhanho neIRD System yedu kunogona kudzikamisa kudzikiswa uku.

Mukuwedzera, iyo PET yakanyunguduka mitsetse haishanduki yero nekuti nguva yekuomesa inoderedzwa (Kuomesa nguva kunongoda 15-20mins, hunyoro hwekupedzisira hunogona kuva ≤ 30ppm, kushandiswa kwesimba kusingasviki 60-80W/KG/H)

④Kuveura muextruder kunoderedzwawo nekuti iyo preheated zvinhu inopinda muextruder nekudziya nguva dzose”

⑤Kuvandudza kubuda kwePET Extruder

Kuwedzera kwehuwandu hwehuwandu negumi kusvika makumi maviri muzana kunogona kuwanikwa muIRD, kunonatsiridza mashandiro ezvekudya pane extruder inlet zvakanyanya - nepo extruder yekumhanyisa inoramba isina kuchinjika, pane yakagadziridzwa kuzadza mashandiro pane screw.

Single Screw Extrusion Pelletizing Line (Pasina Vacuum Venting)

Tichishandisa masimba eSingle screw extruder nekuimisa neLIANDA yakasarudzika screw yakagadzirirwa rPET Bottle flakes, takakwanisa kuwedzera huwandu ne20% nesimba shoma rakapedzwa zvichienzaniswa neParallel double screw extruder.

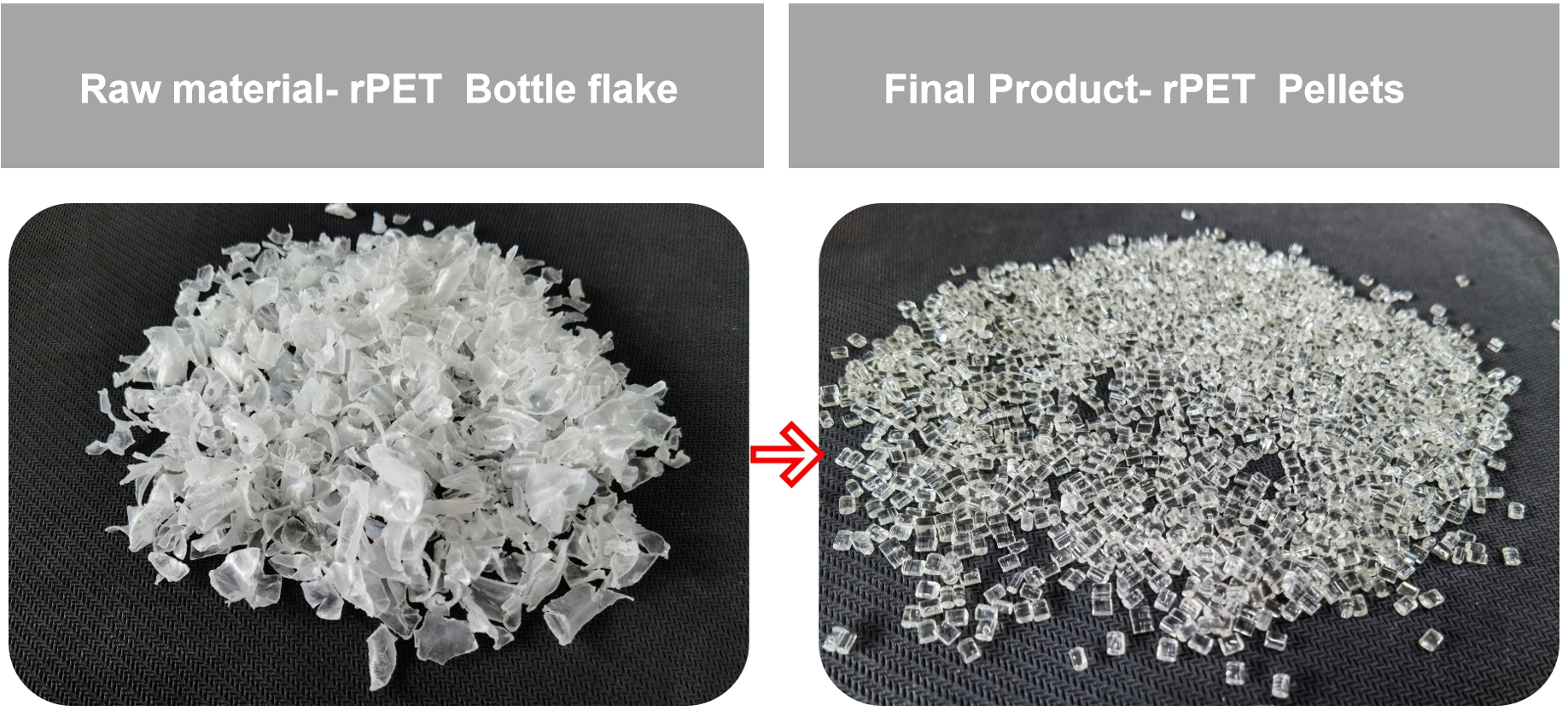

Viscosity yerPET pellets inogadzirwa neyedu system: pane chete ≤0.02-0.03dl/g viscosity kudonha ---pasina kuwedzera chero viscosity enhancer. (Zvinoenderana nekuyedzwa kwedu mumba)

rPET pellets Ruvara: pachena --- pasina kuwedzera chero pachena inosimudzira

Pasina Vacuum venting system --- Kuchengetedza mutengo wesimba, isina matambudziko uye yakagadzikana kushanda

Machine Photos