PET Flake/scrap dehumidifier crystallizer

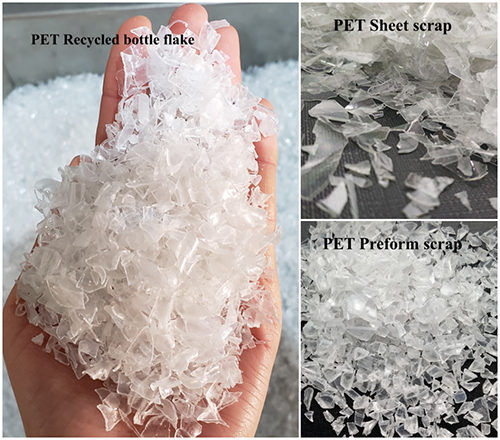

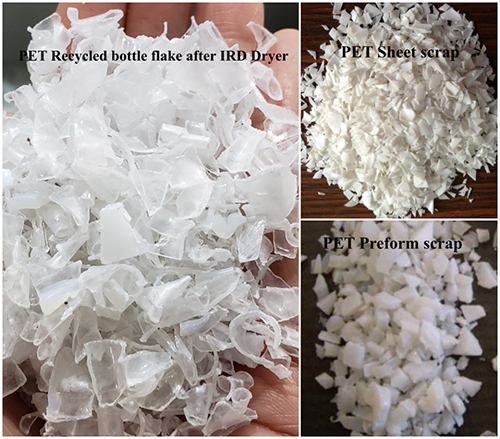

Application Sample

| Raw Material | PET Recycled flake/ PET sheet scrap/PET Preform zvimedu |

|

| Kushandisa Machine | LDHW-600*1000 |  |

| Kuomesa & Crystallized Temperature set | 180-200 ℃Inogona kuchinjika nepfuma yerawmaterial | |

| Crystallized nguva yakatarwa | 20mins | |

| Final material | Crystallized uye Dried PET zvimedu uyehunyoro hwekupedzisira hunogona kuita 30ppm |  |

Mashandiro

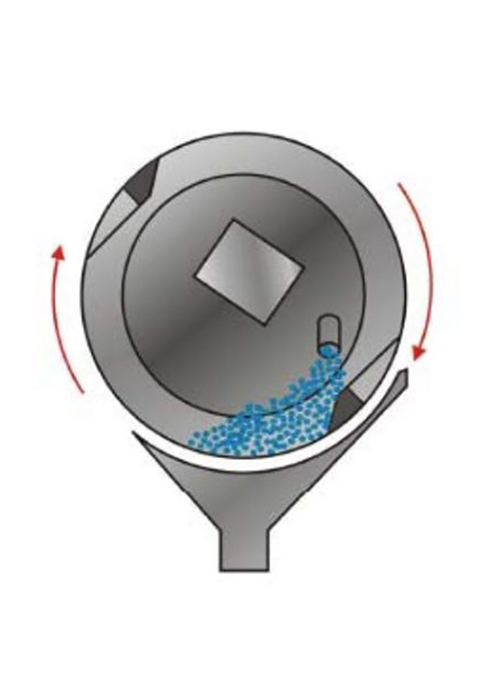

Kudyisa/Kuisa

Dry & Crystallization Processing

Discharging

>> Pakutanga nhanho, chinangwa chega ndechekupisa zvinhu kusvika kune tembiricha yakatarwa.

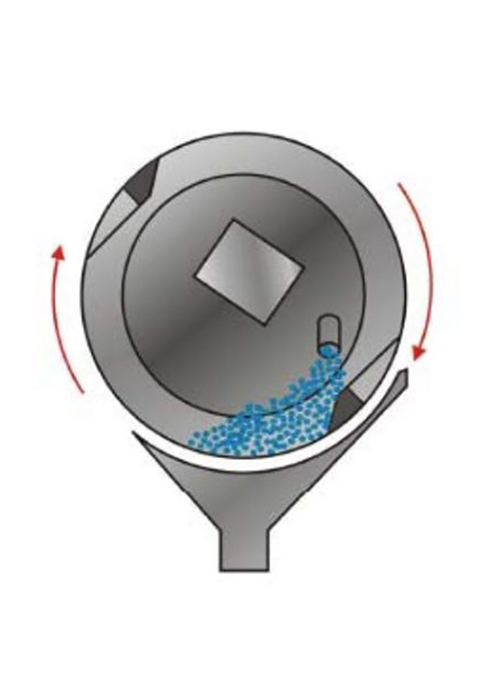

Adopt inononoka kumhanya yedhiramu inotenderera, iyo Infrared mwenje simba reoomesa ichave iri padanho repamusoro, ipapo maPET pellets achave nekudziya nekukurumidza kusvika tembiricha yakwira kusvika kune preset tembiricha.

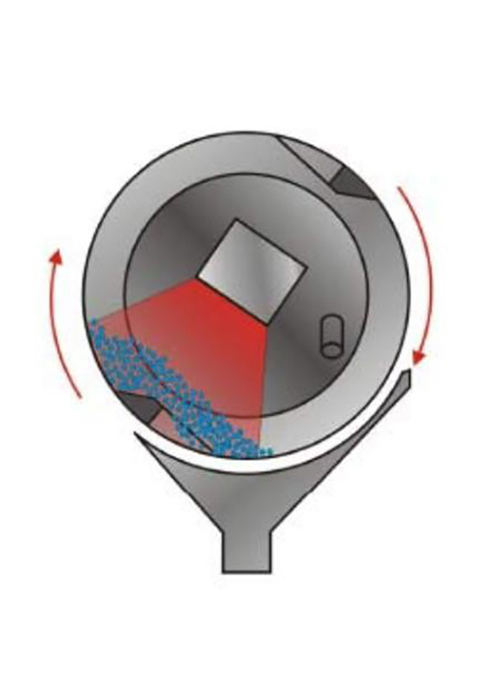

>> Kuomesa & Crystallizing nhanho

Kana zvinhu zvasvika patembiricha, kumhanya kwedhiramu kunowedzerwa kusvika padanho repamusoro rekutenderera kudzivirira kuungana kwezvinhu. Panguva imwecheteyo, simba remarambi e infrared richawedzerwa zvakare kupedzisa kuomeswa. Ipapo ngoma inotenderera sipidhi inodzikiswa zvakare. Kazhinji nzira yekuomesa ichapedzwa mushure me15-20mins. (Nguva chaiyo inoenderana nepfuma yezvinhu)

>> Mushure mekupedza kuomeswa, iyo IR Drum inozoburitsa otomatiki zvinhu uye kuzadza chigubhu kune inotevera kutenderera.

Kuzadza otomatiki pamwe chete nematanho ese akakodzera eakasiyana tembiricha ramps akanyatsobatanidzwa mune iyo-ye-iyo-iyo-inoyevedza Touch Screen control. Kamwe maparamita uye tembiricha profiles zvawanikwa zvechimwe chinhu, zvigadziriso zvemaseti zvinogona kuchengetwa semabikirwo muhurongwa hwekutonga.

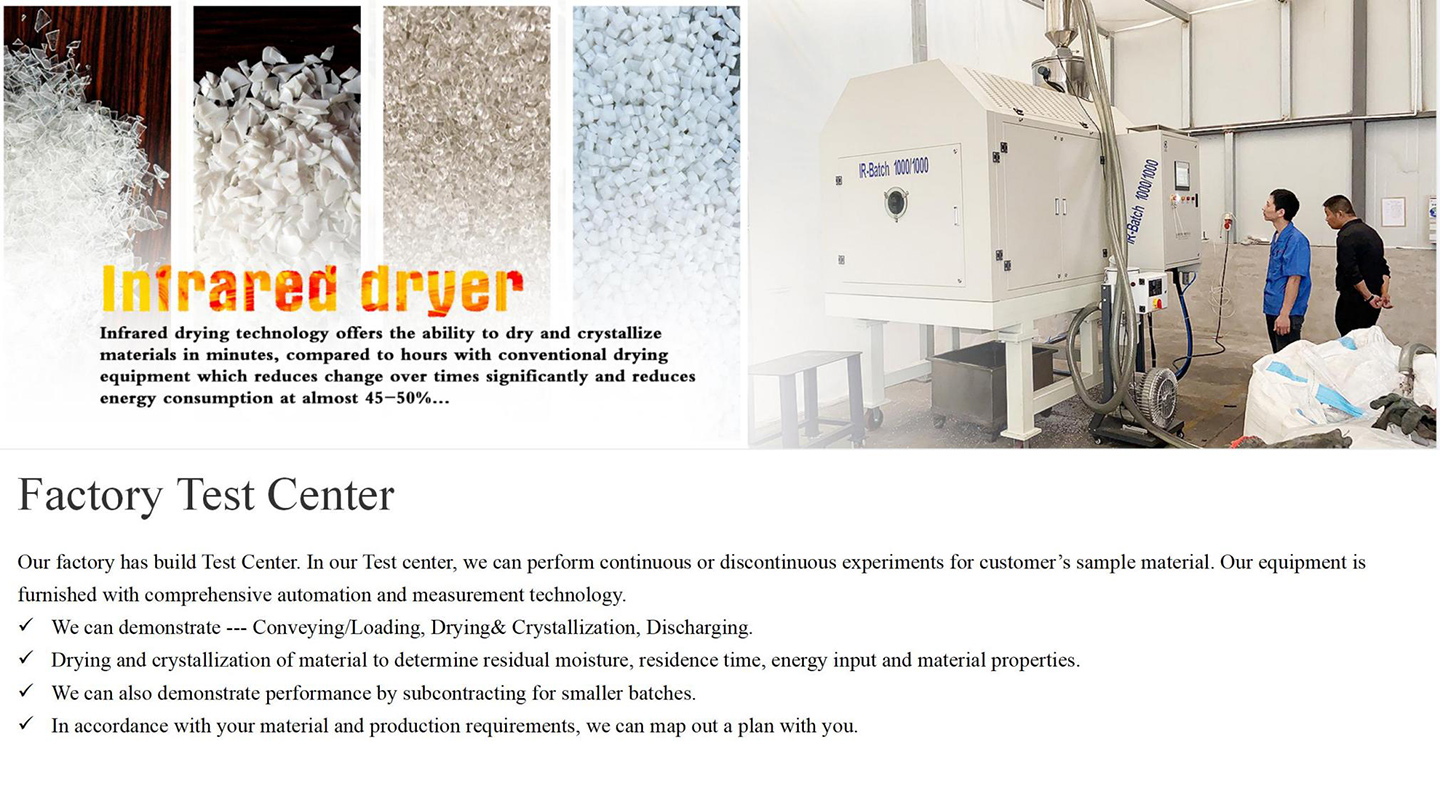

Kubatsira Kwedu

Kazhinji iyo PET Bhodhoro inoputika kana shizha zvimedu zvine hunyoro hwekutanga hunosvika 10000-13000ppm. Iyo PET Bottle flakes kana sheet scrap (Mhandara kana yakasanganiswa) ichagadziridzwa muInfrared crystal dryer mu20mins, tembiricha yekuomesa ichave 150-180 ℃ uye yakaomeswa kusvika 50-70ppm, yobva yapihwa kuSingle screw extruding system kuti ienderere mberi nekugadzirisa.

● Kuderedza hydrolytic degradation ye viscosity.

● Dzivirira kuwedzera kweAA mazinga kune zvinhu zvine chikafu chekubata

● Kuwedzera kukwanisa kwemutsara wekugadzira kusvika ku50%

● Natsa uye ita kuti mhando yechigadzirwa igadzikane-- Yakaenzana uye inodzokororwa inodzokororwa mwando wemukati wezvinhu

● Kusvikira ku60% pasi pesimba rekushandisa pane yakajairwa kuomesa system

● Hapana kupatsanurwa kwezvigadzirwa zvine huwandu hwakawanda hwakasiyana

● Kuzvimiririra tembiricha uye kuomesa nguva yakatarwa

● Kuchena nyore uye kuchinja zvinhu

● Kukurumidza kutanga uye kukurumidza kuvhara

● Uniform crystallization

● Hapana mapellet anoungana & tsvimbo

● Kunyatsobata zvinhu

Kuenzanisa Tafura

| Item | IRD Dryer | Conventional Dryer |

| Transfer medium | Hapana | Hot air |

| Kutamisa kupisa | Zvose mukati nekunze zvidimbu pamwechete. | Kubva kunze kusvika mukati zvishoma nezvishoma. |

| Energy | Sevha ingangoita 20 ~ 50% simba uchienzaniswa neyakaomeswa yechinyakare. | Kudya simba rakawanda. |

| Process time | 1. Crystallization & kuomesa: Zvinogadziriswa panguva imwe chete mukati me8 ~ 15 maminitsi. 2. Kuomesa uye crystallization panguva | 1. Crystallization: Inenge 30 ~ 60 maminitsi. 2. Kuomesa: Inenge 4 ~ 6 maawa. |

| Munyoro | 1. Pasi pe50-70 PPM mushure mokunge IRD yagadziriswa. | 1. Pedza 30 ~ 60 maminetsi kuti uchinje amorphous PET kune crystallized PET kutanga. 2. Pasi pe200PPM mushure memaawa angangoita 4 dehumidifier yakagadziriswa. 3. Pasi pe50 PPM mushure memaawa anopfuura matanhatu dehumidifier yagadziriswa. |

| Nguva yekutungamira | 20mins | Kupfuura maawa matanhatu. |

| Kuchinja kwezvinhu | 1. Nyore & nekukurumidza. 2. Kune chete 1 ~ 1.5 nguva huwandu hwekushandisa kweawa imwe mu buffer hopper. | 1. Zvakaoma & zvishoma nezvishoma. 2. Kune 5 ~ 7 nguva huwandu hwekushandisa kweawa imwe mucrystallizer & hopper. |

| Operation | Nyore--- Ne Siemens PLC kutonga

| Zvakaoma sekuti zvinofanirwa kuisa diki crystallized PET mucrystallizer kana uchitanga kushanda. |

| Maintenance | 1. Nyore. 2. Mari yekuchengetedza yakaderera. | 1. Zvakaoma. 2. Mutengo wepamusoro wekugadzirisa. |

Machine Photos

Material Free Testing

Injiniya ane ruzivo achaita bvunzo. Vashandi vako vanokokwa neushamwari kuti vatore chikamu mumakwara edu akabatana. Saka iwe une zvese mukana wekupa nesimba uye mukana wekuona chaizvo zvigadzirwa zvedu zviri kushanda.

Machine Installation

>> Supply Ane ruzivo mainjiniya kufekitori yako kubatsira kuisirwa uye zvinhu bvunzo kumhanya

>> Adopt aviation plug, hapana chikonzero chekubatanidza waya yemagetsi apo mutengi achiwana muchina mufekitori yake. Kurerutsa danho rekuisa

>> Ipa iyo vhidhiyo yekuvhiya yekumisikidza uye inomhanyisa gwara

>> Tsigiro pamutsetse webasa