Polyester masterbatch crystallizer dryer

Application Sample

| Raw Material | Polyester / PET Inopenya Masterbatch (Bright color masterbatch: polyester spun kubva kupolyester chips ine TiO2 yemukati isingasviki kana kuenzana ne0.1%. Ndiyo imwe yemhando dzakajairwa dzepolyester. Indekisi yemhando yezvidimbu zvakafanana neyepolyester isina kusimba uye yakazara-yakagomara polyester. The crystallization rate inononoka pane iyo yehafu-yepamusoro uye inonamira polyester, isina kuoma uye inonamira polyester. uye tembiricha inofanirwa kudzorwa. |  |

| Kushandisa Machine | LDHW-1200*1000 |  |

| Crystallization Temperature set | 95 ℃ yekutanga nzvimbo; 130 ℃ yechipiri zone, 150 ℃ yechitatu zone | |

| Kuomesa nguva yakatarwa | 25mins | |

| Pakupedzisira chigadzirwa | Yakaomeswa uye yakanatswa Polyester masterbatch hapana clumping, hapana mapellets anonamira |  |

Mashandiro

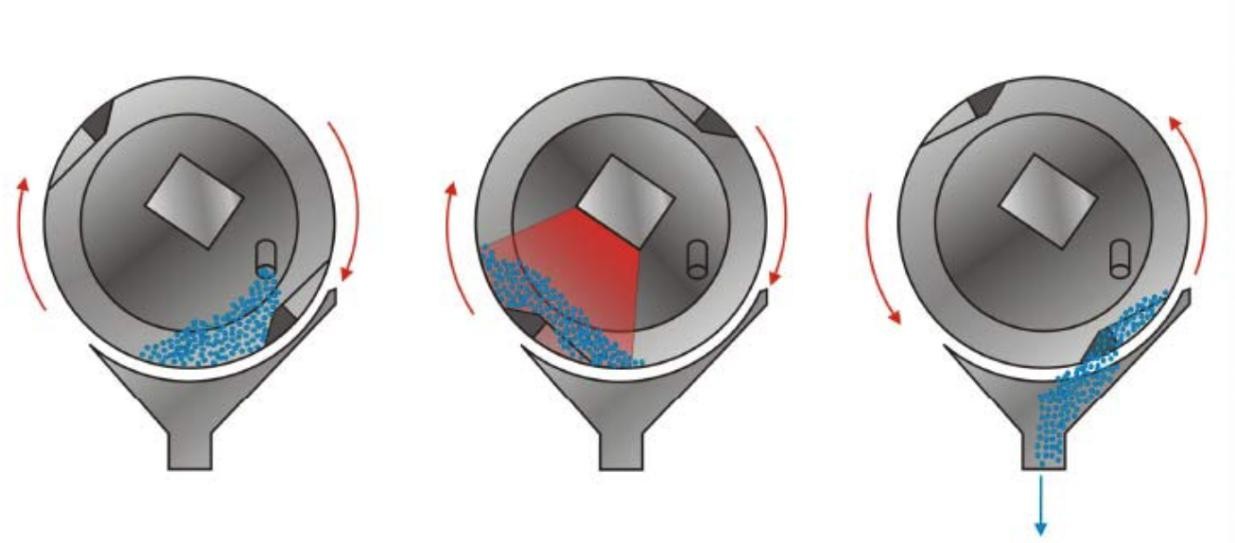

>> Pakutanga nhanho, chinangwa chega ndechekupisa zvinhu kusvika kune tembiricha yakatarwa.

Adopt inononoka kumhanya yedhiramu inotenderera, iyo Infrared mwenje simba reoomesa ichave iri padanho repamusoro, ipapo maPET pellets achave nekudziya nekukurumidza kusvika tembiricha yakwira kusvika kune preset tembiricha.

>> Kuomesa nhanho

Kana zvinhu zvasvika patembiricha, kumhanya kwedhiramu kunowedzerwa kusvika padanho repamusoro rekutenderera kudzivirira kuungana kwezvinhu. Panguva imwecheteyo, simba remarambi e infrared richawedzerwa zvakare kupedzisa kuomeswa. Ipapo ngoma inotenderera sipidhi inodzikiswa zvakare. Kazhinji nzira yekuomesa ichapedzwa mushure me15-20mins. (Nguva chaiyo inoenderana nepfuma yezvinhu)

>> Mushure mekupedza kuomeswa, iyo IR Drum inozoburitsa otomatiki zvinhu uye kuzadza chigubhu kune inotevera kutenderera.

Kuzadza otomatiki pamwe chete nematanho ese akakodzera eakasiyana tembiricha ramps akanyatsobatanidzwa mune iyo-ye-iyo-iyo-inoyevedza Touch Screen control. Kamwe maparamita uye tembiricha profiles zvawanikwa zvechimwe chinhu, zvigadziriso zvemaseti zvinogona kuchengetwa semabikirwo muhurongwa hwekutonga.

Kubatsira Kwedu

| 1 | Pakarepo | Iyo dhizaini yekumhanyisa inogona kutanga pakarepo pakutanga. Chikamu chekudziya-yemuchina hachidiwi. |

| 2 | Inogona kugutsa mhando dzakasiyana dzeMasterbatch | Kuomesa tembiricha uye nguva inogona kuchinjika nepfuma yezvinhu zvakasvibiswa |

| 3 | Hapana kuputika, hapana kunamatira | Kutenderera kwedhiramu kunovimbisa kufamba nguva dzose kwezvinhu.Rotary drying system, kukurumidza kwayo kutenderera kunogona kuwedzerwa zvakanyanya sezvinobvira kuwana kusanganiswa kwakanakisisa kwepellets. Yakanaka mukubvongodza, iyo masterbatch haizobatike Chigadzirwa chacho chinopisa zvakaenzana |

| 4 | Nyore yakachena uye shandura ruvara | Kuwana kwakanaka kune zvese zvikamu zvinobvumira nyore uye nekukurumidza kuchenesa. Rapid chigadzirwa kuchinja-pamusoro. |

| 5 | Maminitsi pane maawa | Simba rinobva raunzwa mukati memukati wechigadzirwa

|

| 6 | Sevha 45-50% mutengo wesimba uchienzaniswa neyakajairwa dehumidifier & Crystallizer | Yakanyanya kuderera mashandisirwo esimba kana ichienzaniswa neyakajairwa maitiro, kuburikidza nekuunzwa kwakananga kwesimba re infrared kune chigadzirwa. |

| 7 | Siemens PLC kutonga | Kudzora.Iyo data data, senge zvinhu uye kupera kwemhepo tembiricha kana mazinga ekuzadza anoramba achitariswa nenzira yemasensa uye pyrometers. Kutsauka kunokonzeresa otomatiki kugadzirisa. Reproducibility.Recipes uye maitiro ekugadzirisa zvinogona kuchengetwa muhurongwa hwekutonga kuti ive nechokwadi chekugadzirisa uye kubereka migumisiro. Remote kugadzirisa.Online service kuburikidza nemodemu. |

Machine Photos

Material Free Testing

Fekitori yedu ine kuvaka Test Center. Munzvimbo yedu yeTest, tinogona kuita zviyedzo zvinoenderera kana zvisingaendereki kune zvemutengi sampuli zvinhu. Midziyo yedu inopihwa yakazara otomatiki uye kuyerwa tekinoroji.

• Tinogona kuratidza --- Kutakura/Kuisa, Kuomesa & Crystallization, Discharging.

• Kuomesa uye crystallization yezvinhu kuti zvione zvakasara mwando, nguva yekugara, simba rekuisa uye zvinhu.

• Tinogonawo kuratidza mashandiro nekuita subcontracting kumabhechi madiki.

• Maererano nezvinhu zvako uye zvinodiwa zvekugadzira, tinogona kuronga hurongwa newe.

Injiniya ane ruzivo achaita bvunzo. Vashandi vako vanokokwa neushamwari kuti vatore chikamu mumakwara edu akabatana. Saka iwe une zvese mukana wekupa nesimba uye mukana wekuona chaizvo zvigadzirwa zvedu zviri kushanda.

Machine Installation

>> Supply Ane ruzivo mainjiniya kufekitori yako kubatsira kuisirwa uye zvinhu bvunzo kumhanya

>> Adopt aviation plug, hapana chikonzero chekubatanidza waya yemagetsi apo mutengi achiwana muchina mufekitori yake. Kurerutsa danho rekuisa

>> Ipa iyo vhidhiyo yekuvhiya yekumisikidza uye inomhanyisa gwara

>> Tsigiro pamutsetse webasa