TPEE Dryer & VOC Cleaner

Application Sample

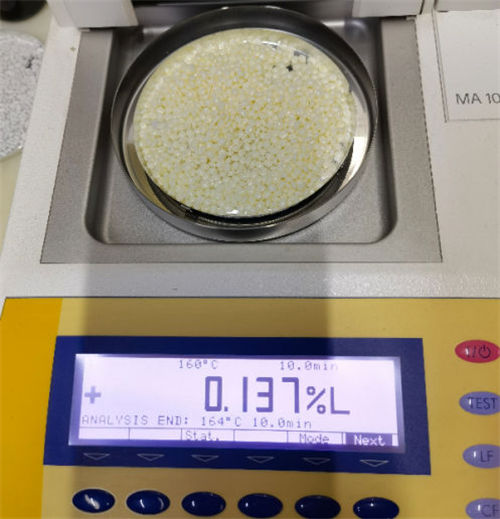

| Raw Material | TPE Pellets naSK Chemical |   |

| Kushandisa Machine | LDHW-1200*1000 |  |

| Kunyorova kwekutanga | 1370ppm Yakaedzwa neGerman Sartorius Moisture test instrument |  |

| Drying Temperature set | 120 ℃ (zvinhu tembiricha chaiyo panguva yekuomesa) | |

| Kuomesa nguva yakatarwa | 20mins | |

| Kunyorova kwekupedzisira | 30ppm Yakaedzwa neGerman Sartorius Moisture test instrument |  |

| Pakupedzisira chigadzirwa | Yakaomeswa TPE hapana clumping, hapana pellets inonamira |  |

Mashandiro

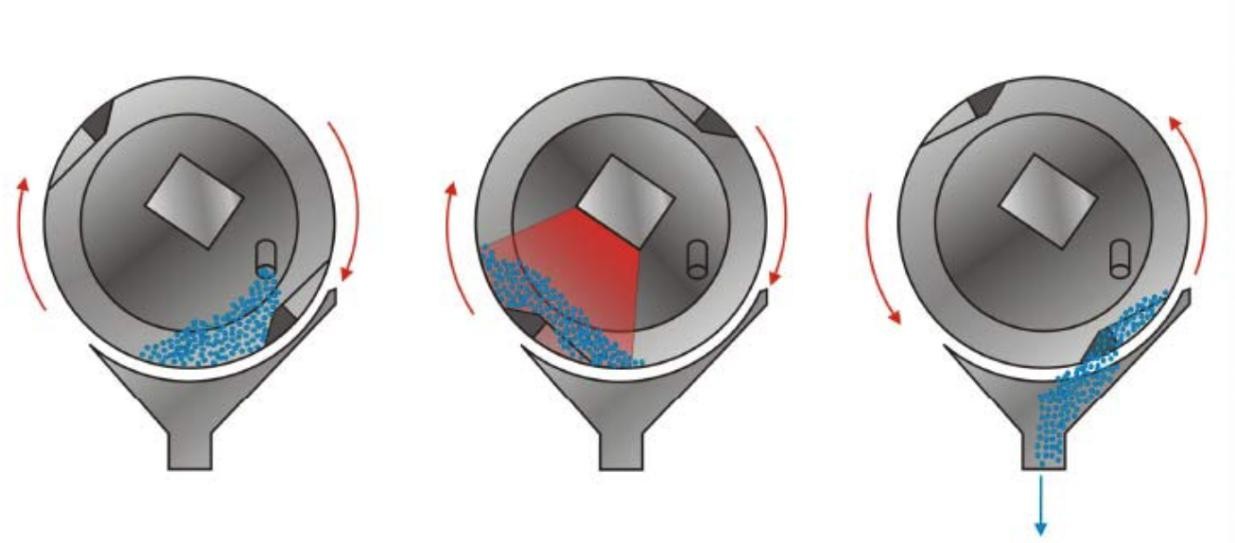

>> Pakutanga nhanho, chinangwa chega ndechekupisa zvinhu kusvika kune tembiricha yakatarwa.

Gamuchira inononoka kumhanya kwedhiramu inotenderera, iyo Infrared mwenje simba remuomese ichange iri padanho repamusoro, ipapo PETG pellets ichave nekudziya nekukurumidza kusvika tembiricha yakwira kusvika kune yakagara yakatarwa.

>> Kuomesa nhanho

Kana zvinhu zvasvika patembiricha, kumhanya kwedhiramu kunowedzerwa kusvika padanho repamusoro rekutenderera kudzivirira kuungana kwezvinhu. Panguva imwecheteyo, simba remarambi e infrared richawedzerwa zvakare kupedzisa kuomeswa. Ipapo ngoma inotenderera sipidhi inodzikiswa zvakare. Kazhinji nzira yekuomesa ichapedzwa mushure me15-20mins. (Nguva chaiyo inoenderana nepfuma yezvinhu)

>> Mushure mekupedza kuomeswa, iyo IR Drum inozoburitsa otomatiki zvinhu kuti vacuum devolatilization system yeVOC Kubvisa.

>> Devolatilization system yeVOC Kubvisa

Iyo infrared devolatilization system inonyanya kuenderera mberi ichipisa zvinhu kuburikidza neiyo infrared radiation ine chaiyo wavelength, nepo zvinhu zvichidziirwa kusvika kune preset tembiricha, iyo yakaomeswa inopihwa kuVacuum devolatilization system yekudzokororwa vacuumization devolatilization, pakupedzisira mavhuvhu anoburitswa nezvinhu zvinopisa anoburitswa neVacuum system. Uye iyo Volatile nyaya yemukati inogona kuve <10ppm

Kubatsira Kwedu

| 1 | Kuderera kwesimba rekushandisa | Yakanyanya kuderera mashandisirwo esimba kana ichienzaniswa neyakajairwa maitiro, kuburikidza nekuunzwa kwakananga kwesimba re infrared kune chigadzirwa. |

| 2 | Maminitsi pane maawa | Chigadzirwa chacho chinoramba chiri kwemaminetsi mashoma mukuomesa uye chinobva chavepo kune mamwe matanho ekugadzira.

|

| 3 | Pakarepo | Iyo dhizaini yekumhanyisa inogona kutanga pakarepo pakutanga. Chikamu chekudziya-yemuchina hachidiwi.

|

| 4 | Zvinyoronyoro | Nyaya yacho inopisa zvinyoronyoro kubva mukati kuenda kunze uye haina kutakurwa kubva kunze kwemaawa nekupisa, uye zvichidaro yakakuvadzwa.

|

| 5 | In one step | Crystallization uye kuomesa mune imwe nhanho |

| 6 | Kuwedzera kwekushandisa | Kuwedzera kwekudyara kwekudyara nenzira yekudzikisa mutoro pane extruder |

| 7 | Hapana kuputika, hapana kunamatira | Kutenderera kwechigubhu kunovimbisa kugara kwekufamba kwezvinhu. Iyo spiral coils uye kusanganisa zvinhu zvakagadzirirwa chigadzirwa chako inovimbisa musanganiswa wakakwana wezvinhu uye inodzivirira kuungana. Chigadzirwa chacho chinopisa zvakaenzana |

| 8 | Siemens PLC kutonga | Kudzora.Iyo data yemaitiro, senge zvinhu uye kupera tembiricha yemhepo kana mazinga ekuzadza anoramba achitariswa kuburikidza nemasensor uye pyrometers. Kutsauka kunokonzeresa otomatiki kugadzirisa. Reproducibility.Recipes uye maparamendi ekugadzirisa anogona kuchengetwa mune yekudzora sisitimu kuti ive neyakakwana uye inobereka mhedzisiro. Kuchengetedza kure.Online service kuburikidza ne modem. |

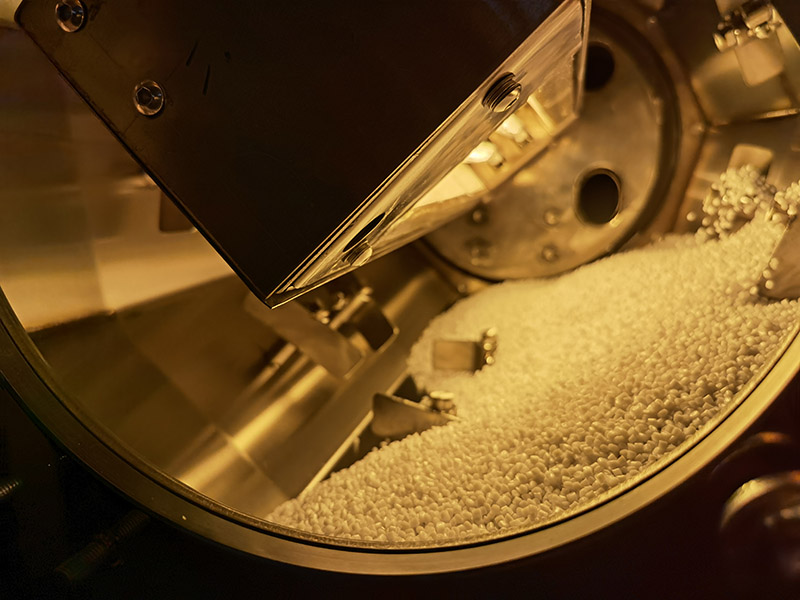

Machine Photos

Machine Application

| Kuomesa | Kuomesa epurasitiki granulates (PET, TPE, PETG, APET, RPET, PBT, ABS/PC, HDPE, LCP, PC, PP, PVB,WPC, TPU nezvimwewo) pamwe nezvimwe zvinhu zvakawanda zvinoyerera zvakasununguka. |

| Crystallization | PET (Bottle flakesm granulates, sheet scrap), PET Masterbatch, CO-PET, PBT, PEEK, PLA, PPS nezvimwe. |

| Diverse | Thermal processed kubviswa kwekuzorora oligomeren uye volatile components |

Material Free Testing

Fekitori yedu ine kuvaka Test Center. Munzvimbo yedu yeTest, tinogona kuita zviyedzo zvinoenderera kana zvisingaendereki kune zvemutengi sampuli zvinhu. Midziyo yedu inopihwa yakazara otomatiki uye kuyerwa tekinoroji.

• Tinogona kuratidza --- Kutakura/Kuisa, Kuomesa & Crystallization, Discharging.

• Kuomesa uye crystallization yezvinhu kuti zvione zvakasara mwando, nguva yekugara, simba rekuisa uye zvinhu.

• Tinogonawo kuratidza mashandiro nekuita subcontracting kumabhechi madiki.

• Maererano nezvinhu zvako uye zvinodiwa zvekugadzira, tinogona kuronga hurongwa newe.

Injiniya ane ruzivo achaita bvunzo. Vashandi vako vanokokwa neushamwari kuti vatore chikamu mumakwara edu akabatana. Saka iwe une zvese mukana wekupa nesimba uye mukana wekuona chaizvo zvigadzirwa zvedu zviri kushanda.

Machine Installation

>> Supply Ane ruzivo mainjiniya kufekitori yako kubatsira kuisirwa uye zvinhu bvunzo kumhanya

>> Adopt aviation plug, hapana chikonzero chekubatanidza waya yemagetsi apo mutengi achiwana muchina mufekitori yake. Kurerutsa danho rekuisa

>> Ipa iyo vhidhiyo yekuvhiya yekumisikidza uye inomhanyisa gwara

>> Tsigiro pamutsetse webasa