PET Granulating line

Infrared Crystallization Dryer bakeng sa mohala oa granulating oa rPET Extrusion

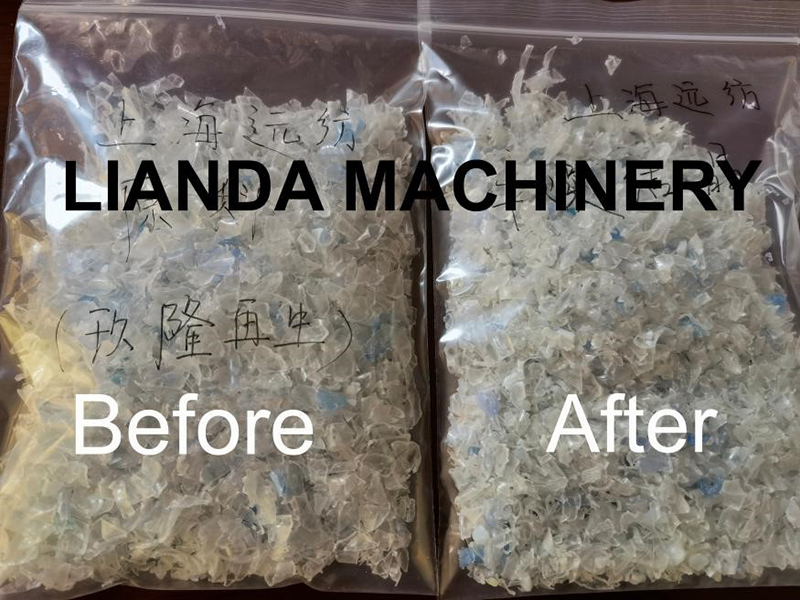

Infrared Pre-Drying ea rPET Bottle Flakes: Ho eketsa Sephetho le ho Ntlafatsa Boleng ba PET Extruders

Ho omisa ke phetoho e le 'ngoe ea bohlokoa ka ho fetisisa ts'ebetsong.

>> Ho ntlafatsa thepa le thepa ea 'mele ea PET e sebelisoang hape, ea boemo ba lijo ka theknoloji e tsamaisoang ke leseli la infrared e na le karolo ea bohlokoa eo e lokelang ho e bapala thepa ea intrinsic viscosity (IV)

>> Pele ho kristale le ho omisoa ha li-flakes pele ho extrusion ho thusa ho fokotsa tahlehelo ea IV ho tsoa ho PET, ntlha ea bohlokoa bakeng sa ho sebelisoa hape ha resin.

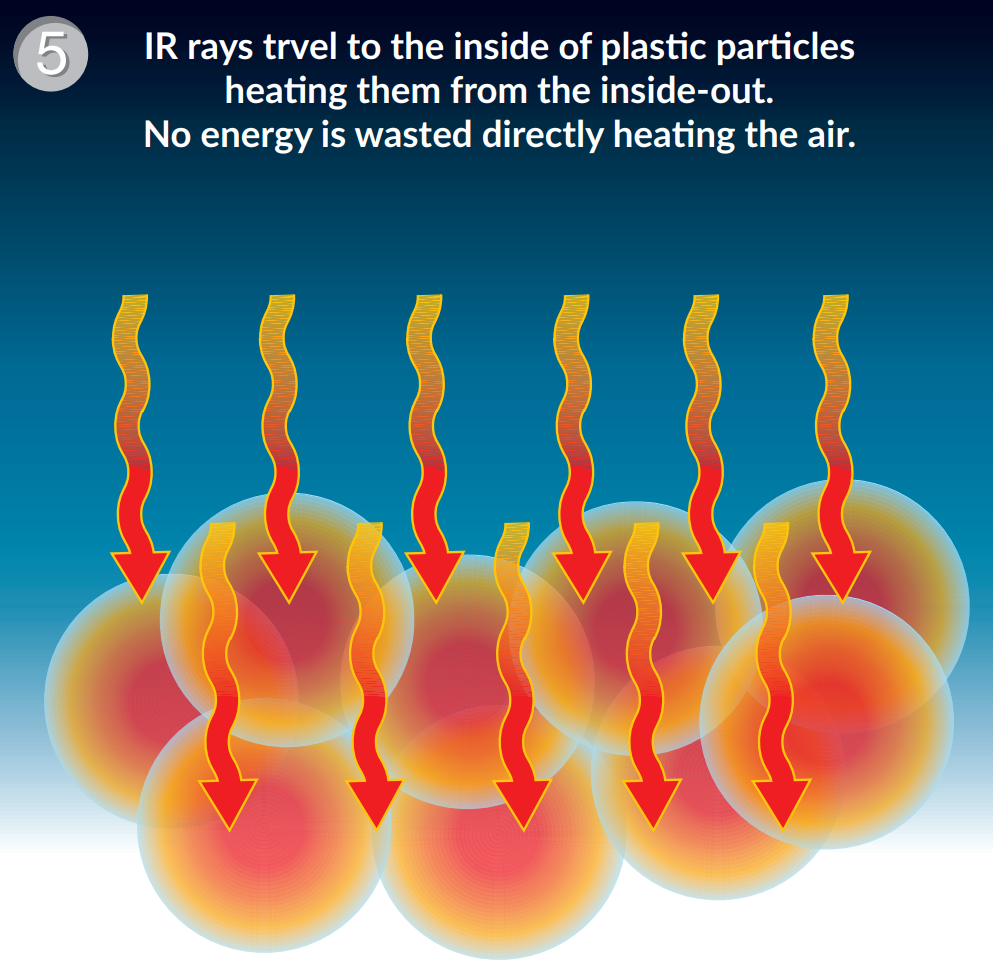

>> Ho tsosolosa li-flakes ka extruder ho fokotsa IV ka lebaka la hydrolysis i ho ba teng ha metsi, 'me ke ka lebaka leo ho omisa pele ho boemo ba ho omisa ka mokhoa oa IRD oa rona ho ka fokotsa phokotso ena. Ho phaella moo,PET melt strips ha e fetohe mosehla hobane nako ea ho omisa e fokotsehile(Nako ea ho omisa e hloka feela 15-20mins, mongobo oa ho qetela o ka ba ≤ 30ppm, tšebeliso ea matla e ka tlase ho 80W / KG / H)

>> Ho kuta ka har'a extruder ho boetse ho fokotsehile hobane thepa e futhumetseng e kena ka har'a mocheso o sa khaotseng "

>> Ho ntlafatsa tlhahiso ea PET Extruder

Keketseho ea bongata ba bongata ka 10 ho isa ho 20 % e ka finyelloa ho IRD, ea ntlafatsa ts'ebetso ea phepelo sebakeng sa extruder haholo - ha lebelo la extruder le ntse le sa fetohe, ho na le ts'ebetso e ntlafalitsoeng haholo ea ho tlatsa sekoti.

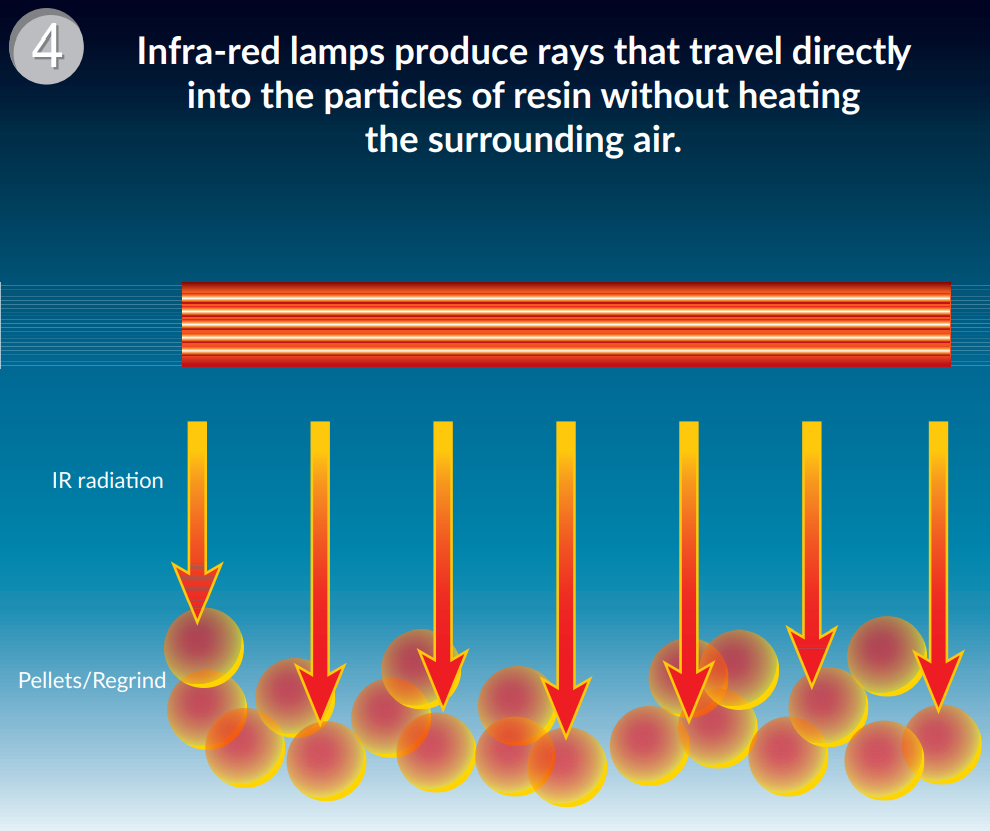

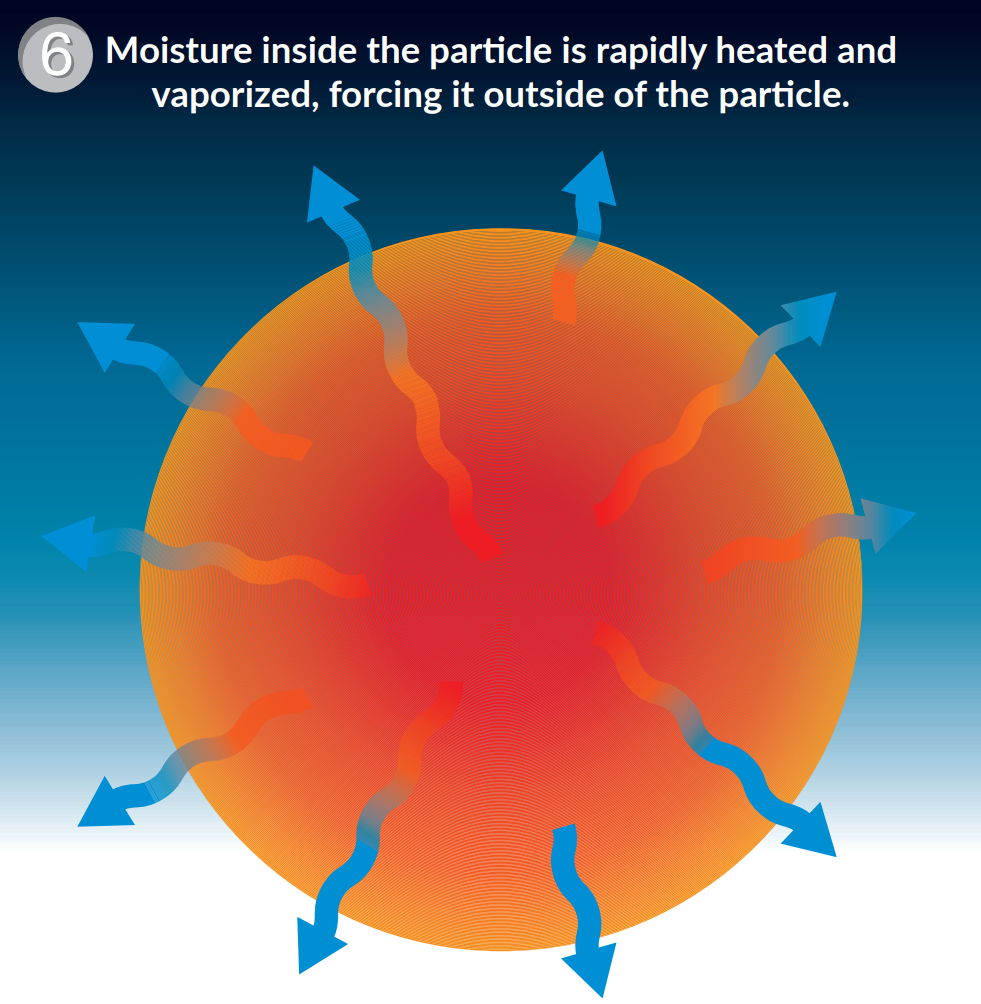

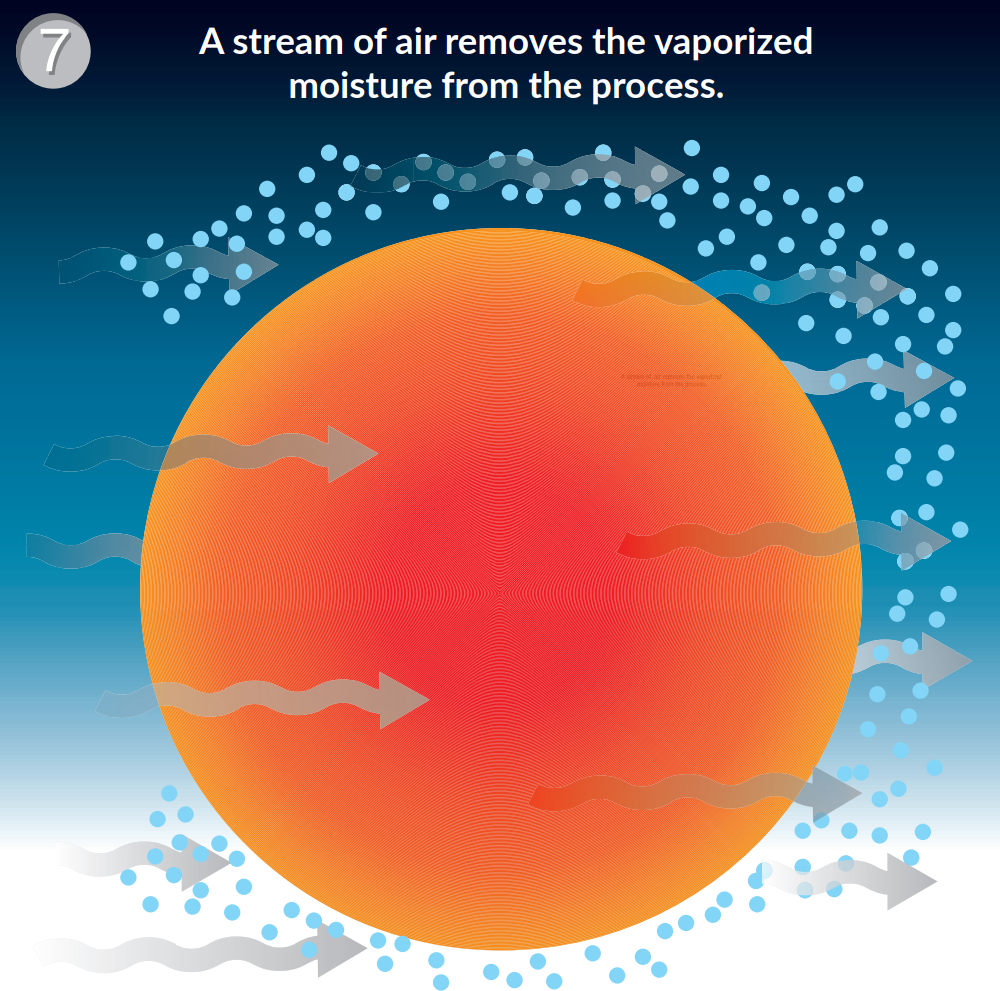

Molao-motheo oa ho Sebetsa

Molemo oo re o Etsang

※Ho fokotsa ho senyeha ha hydrolytic ea viscosity.

※ Thibela ho eketseha ha maemo a AA bakeng sa lisebelisoa tse amanang le lijo

※ Ho eketsa bokhoni ba mohala oa tlhahiso ho fihla ho 50%

※ Ntlafatsa le ho etsa hore boleng ba sehlahisoa bo be bo tsitsitseng-- Mongobo o lekanang le o phetoang oa thepa

→ Fokotsa litšenyehelo tsa tlhahiso ea li-pellets tsa PET: Ho fihla ho 60% ka tlase ho tšebeliso ea matla ho feta mokhoa o tloaelehileng oa ho omisa

→ Ho qala hang-hang le ho koala kapele --- Ha ho hlokahale ho futhumatsa pele

→ Ho omisa le ho kristale ho tla sebetsoa ka mohato o le mong

→ Mohala oa mochini o na le sistimi ea Siemens PLC e nang le ts'ebetso e le 'ngoe ea bohlokoa ea memori

→ E akaretsa sebaka se senyane, se bonolo ho sebetsa le ho se hlokomela

→ mocheso o ikemetseng le nako ea ho omisa e behiloeng

→ Ha ho na karohano ea lihlahisoa tse nang le bongata bo fapaneng

→ Ho hloekisa habonolo le ho fetola thepa

Ho Tsamaisa Mechini fekthering ea Bareki

LBH

P: Mongobo oa ho qetela oo u ka o fumanang ke ofe? A na u na le meeli ho mongobo oa pele oa thepa e tala?

A: Mongobo oa ho qetela oo re ka o fumanang ≤30ppm (Nka PET e le mohlala). Mongobo oa pele o ka ba 6000-15000ppm.

P: Re sebelisa Double parallel screw extruding le vacuum degassing system bakeng sa PET Extrusion granulating line, na re ntse re hloka ho sebelisa pre-dryer?

A: Re fana ka maikutlo a ho sebelisa Pre-dryer pele ho extrusion. Hangata sistimi e joalo e na le tlhoko e tiileng ea mongobo oa pele oa lisebelisoa tsa PET. Joalo ka ha re tseba PET ke mofuta oa thepa e ka monyang mongobo o tsoang sepakapakeng e tla etsa hore mohala oa extrusion o sebetse hampe. Kahoo re fana ka maikutlo a ho sebelisa pre-dryer pele ho sistimi ea hau ea extrusion:

>> E fokotsa ho senyeha ha hydrolytic ea viscosity

>>Thibela ho eketseha ha maemo a AA bakeng sa lisebelisoa tse amanang le lijo

>> Ho eketsa bokhoni ba mohala oa tlhahiso ho fihla ho 50%

>> Ntlafatso le ho etsa hore boleng ba sehlahisoa bo tsitsitse-- Mongobo o lekanang le o phetoang oa thepa

P: Nako ea ho fana ka Ird ea hau ke mang?

A: Matsatsi a 40 a ho sebetsa ho tloha ha re fumana depositi ea hau akhaonteng ea rona ea k'hamphani.

P: Ho thoe'ng ka ho kenya IRD ea hau?

Moenjineri ea nang le boiphihlelo a ka u thusa ho kenya sistimi ea IRD bakeng sa hau fekthering ea hau. Kapa re ka fana ka litšebeletso tsa tataiso inthaneteng. Mochini oohle o sebelisa plug ea sefofane, e bonolo bakeng sa khokahano.

P: IRD e ka sebelisoa bakeng sa eng?

A: E ka ba pre-dryer bakeng sa

- PET/PLA/TPE Sheet extrusion line line

- Mohala oa mochini oa PET Bale o etsa mohala

- PET masterbatch crystallization le ho omisa

- PETG Sheet extrusion line

- Mochine oa PET monofilament, PET monofilament extrusion line, PET monofilament bakeng sa lefielo

- PLA /PET Mochini oa ho etsa lifilimi

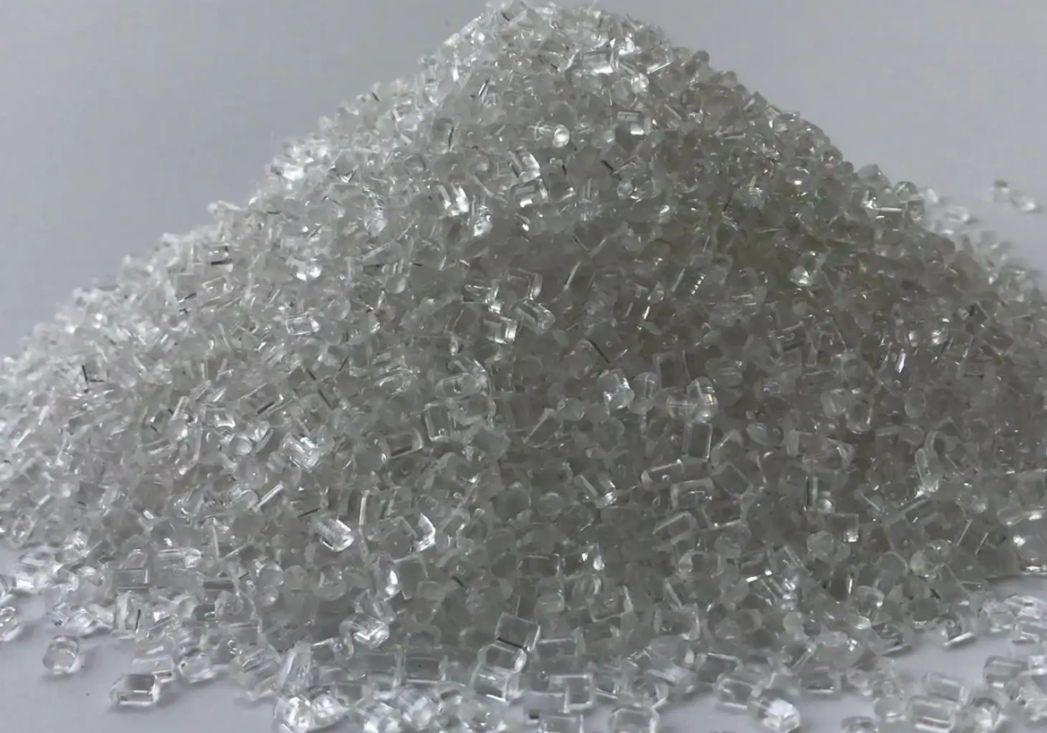

- PBT, ABS/PC, HDPE, LCP, PC, PP, PVB, WPC, TPE, TPU, PET (Bottleflakes, granules, flakes), PET masterbatch, CO-PET, PBT, PEEK, PLA,PBAT, PPS joalo-joalo.

- Mekhoa ea mocheso bakeng saho tlosoa ha oligomeren ea phomolo le likarolo tse sa tsitsang.