The Compact Repelletizing Solution for Film

Product Details

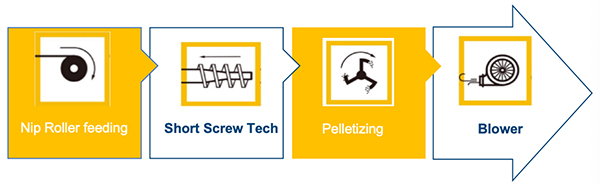

Film Series Repelletizing Solution --- Air Cooling Recycling Extruder

The waste material is directly fed into the screw meaning no prior size reduction is required. Due to this, little or no dust is produced which means a higher quality pellet with the lowest levels of gels possible.

The short screw technology ensures low shear and runs at low melt temperatures guaranteeing an absolute minimum of material degradation producing the highest quality recycled pellet.

What You Care in the Production

Lower running cost and the quickest return on your investment

>> Minimal energy consumption & the high output.

>> Low shear, minimum process dwell time and the absolute minimum of material degradation.

>> Direct extrusion design, no prior size reduction required Requires no other costly equipment.

>> ANTISTATIC BAR on the top of the Trim Basket to remove static from trims.

>> Trim basket for feeding in line trims into the recycling extruder.

>> Reelfeed is used to feed off-spec or scrap reels into the extruder, can be used simultaneously with the trim basket.

>> Direct extrusion design, no prior size reduction required.

Applied for the Material

In addition to high quality, the particles of the same size can also make the composition of the new material uniform and coordinated.

Machine Photos