Isisomisi sekristale esine-infrared se-R-PET Pelletizing/ Extrusion Line

I-Infrared Pre-Drying yePET Flakes: Ukunyusa imveliso kunye nokuphucula uMgangatho kwi-PET Extruders

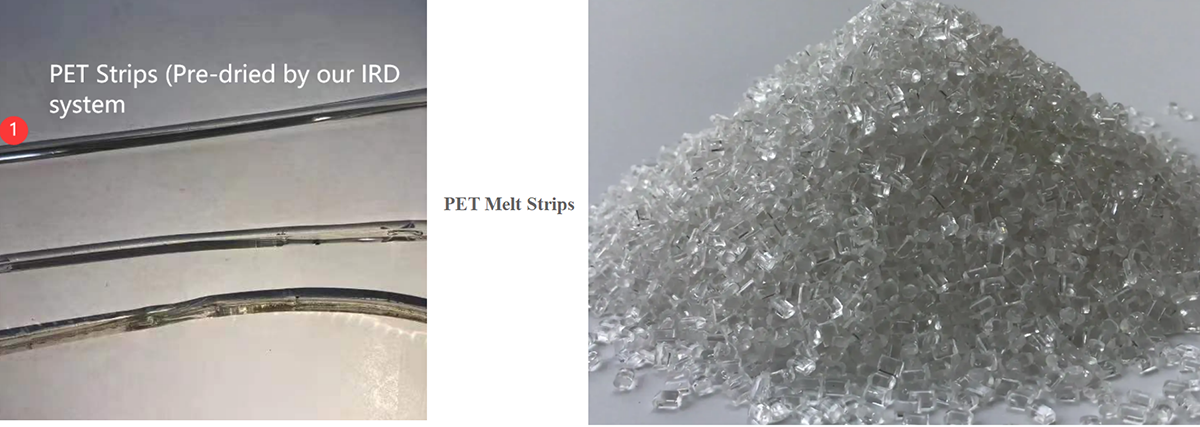

>> Ukuhlaziya iiflakes kwi-extruder kunciphisa i-IV ngenxa ye-hydrolysis i ubukho bamanzi,kwaye yiyo loo nto ukomisa kwangaphambili ukuya kwinqanaba lokumisa elilinganayo kunye neNkqubo yethu ye-IRD kunokunciphisa oku kuncitshiswa. Ukongeza, i-resin ayiphuzi ngenxa yokuba ixesha lokumisa liyancipha (Ixesha lokumisa lifuna kuphela i-15-20mins, ukufuma kokugqibela kunokuba≤ 50ppm, ukusetyenziswa kwamandla ngaphantsi kwe80W/KG/H)

>> Kwinyathelo lokuqala, i-PET regrind yenziwe ngekristale kwaye yomiswe ngaphakathi kwe-IRD ngaphakathi kwexesha elimalunga nemizuzu eli-15. Le crystallization kunye nenkqubo yokomisa iphunyezwa yinkqubo yokufudumala ngokuthe ngqo usebenzisa i-Infrared radiation, ukuphumeza ubushushu bezinto eziphathekayo ze-170˚C. Ngokwahlukileyo kwiinkqubo zomoya oshushu ocothayo, igalelo lamandla elikhawulezayo nelithe ngqo liququzelela ukulinganisa okugqibeleleyo kokuguquguquka ngokusisigxina amaxabiso okufuma okuguquguqukayo - inkqubo yolawulo lwemitha ye-IR ivumela ukuphendula kwiimeko zenkqubo ezitshintshiweyo ngemizuzwana. Ngale ndlela, amaxabiso aphakathi kwe-5,000 kunye ne-8,000 ppm ancitshiswa ngokufanayo ngaphakathi kwe-IRD ukuya kwinqanaba lokufuma elishiyekileyo malunga ne-30-50ppm.

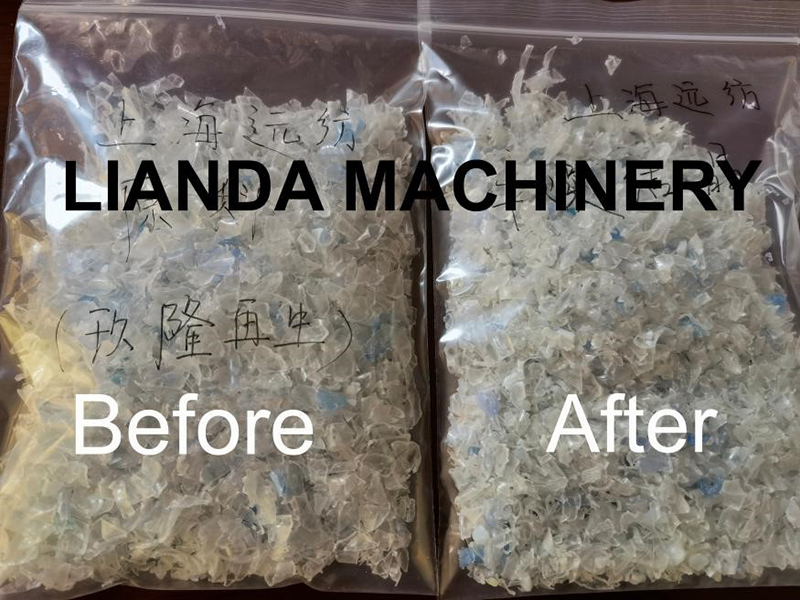

>>Njengomphumo wesibini wenkqubo ye-crystallization kwi-IRD, ubuninzi bobuninzi bezinto zomhlaba buyanda,ngakumbi kwiiflakes ezinobunzima obulula kakhulu. Esi siphumo sesibini sinomdla kakhulu xa kujongwa imvelaphi yokuba ukutyekela kwiibhotile ezinodonga olucekethekileyo kuthintele imathiriyeli yokurisayikilisha ekufezekiseni uxinano lwesambuku > 0.3 kg/dm³. Ukunyuka kobuninzi be-bulk nge-10 ukuya kwi-20 % kunokufezekiswa kwi-IRD, ebonakala ingabalulekanga ekuqaleni kokubona, kodwa iphucula ukusebenza kwesondlo kwi-extruder inlet kakhulu - ngelixa isantya se-extruder sihlala singatshintshi, kukho ukuphuculwa kakhulu kokuzaliswa kokusebenza kwi-screw.

Ixesha lokuposa: Apr-07-2023