Ifilimu iqulathe umgca wokungena

Inyathelo elinye leNyathelo le-PP Raffia, olukiweyo ne-PE / PP Inkunkuma yefilimu

Ifilimu yokuphinda isebenze ngokutsha i-granulator eyoyiweyo ngoomatshini base-I-Linenda, i-Pellerisoon eshushu, i-Pelletising, i-Pelleting kunye nokomisa ingxaki:

■ Umngcipheko wokutyiswa kwencwadi

■ isikhundla sokukhulisa amandla sincinci

■ Ukusetyenziswa kwemali okuqhekekayo kokuqhekeka kokutyumza kunye nokuphuma kuphakathi

I-paricle ubungakanani bemitya ayifani, kwaye imitya iphulwe ngokulula

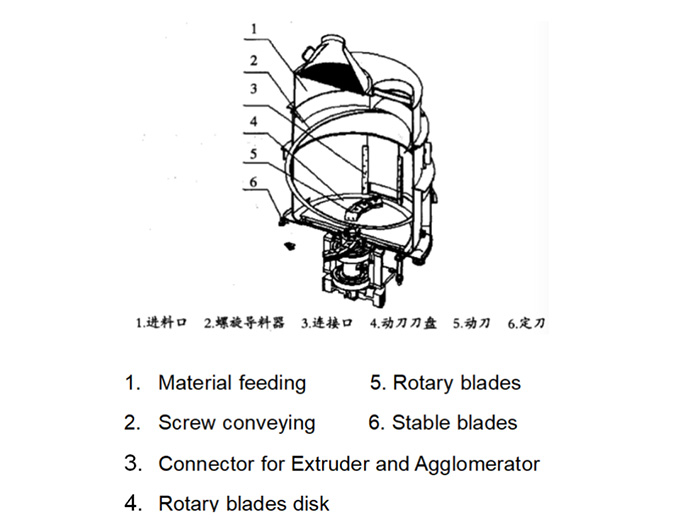

Isixhobo semiboniso bhanyabhanya yamkela indlela yokuqulala kunye nokutyumka. Emva kokuba izinto ezenziweyo zondliwe kwi-compactor, ziya kutyunyuzwa yintloko emazantsi, kunye nengxabano eveliswe kukusika isantya esiphezulu sentloko yesikithi esivelisa ubushushu besixhobo kwaye sandisa inani elondlayo. Le ndlela yenkqubo inoncedo olukhulu lokwandisa amandla emveliso

Iinkcukacha zoMatshini

| Igama lomatshini | Ifilimu iqulathe umgca wokungena |

| Imveliso yokugqibela | I-pellets zeplastiki / igranule |

| Icandelo leCandelo leMveliso | Ibhanti yokuhambisa, i-cutter plactoctor ye-barrel, i-Trunder, icandelo le-Pelleting, iyunithi yokupholisa amanzi, iyunithi eyomisayo, itanki ye-SILO |

| Izixhobo zesicelo | I-HDPE, ldpe, lddpe, i-PP, ye-BPP, i-CPP, i-PP, i-PC, PC, PP, PP, PP, PP, PP, PP, PP, PP, PP, PP, PP, PP, PP, P PU |

| Ukondla | Ibhanti ye-collor |

| Ububanzi be-screw | I-65-180mmm |

| Screw l / d | 30/1; 32/1; 34/1; 36/1 |

| Uluhlu lwemveliso | I-100-1200kg / h |

| Izixhobo ze-SCOWN | I-38cROaLA |

| Ukudinwa | Ukudinwa okungatshatanga okanye ukuphinda-phinda kabini, kungafakwanga ifilimu engashicilelwanga (ngokwezifiso) Uhlobo lwesigaba esibini |

| Uhlobo lokusika | Amanzi aRing Ring Fact okanye i-Strand ife |

| I-Screen Changer | Indawo yokusebenzela kabini i-Hydraulic Screen Changer Itshintsha okanye ihleliwe |

| Uhlobo lokupholisa | Ipholile |

Iinkcukacha zoomatshini ezibonisiweyo

>> ISIQINISEKISO SESIFUNDO

>> Ifilimu yefilimu / i-Agglometor yenzelwe ngefestile yokujonga ukulungiselela abathengi ukuba bavule, bacoce kwaye batshintshe amabala

>> Emva kokuba i-quactoctor ingenayo, ityumkile kwaye idityaniswe, kunye nesantya esijikelezayo esijikelezayo siphosa umxholo kwi-screw-screw entsalela kwindlela yokuhamba. Iqondo lobushushu eliphakamileyo linokwenziwa kwi-compactor, liqulathe iplastiki kwiipellets kwaye

>> I-Pelletizer ye-Telletizer, isantya se-Pelleting ilawulwa yi-inverter, kubandakanya ukusika ishushu sifa, i-diverter cone, ikhare, i-knufe disc, ibha ye-knufe, ifa, i-knufer dis njl njl

>> AKUKHO BUNGOZI ICYDRAUL SCreen Chaprimer Instayisi, Kukho isifo senzuzo kwiNtloko yeFefi ukuya kutshintshiselana ngokukhawuleza kwesikrini, akukho mfuneko yokumisa utshintsho lwekrini, kunye notshintsho olukhawulezileyo

>> Iipellets ziya kunqunyulwa ngqo kwiNtloko ye-FAIRE-I-FIF, kwaye iipellets ziya kutyala umatshini wokuthoba umhlaba emva kokuba amanzi apholile, ingxaki yokuqhawula umtya;

Inkqubo yokulawula

■ Ukondla: I-Benti Transuquor Rings okanye akuxhomekekanga kwimali yombane yefilimu / i-Agglomerator. I-Benti Coneor iya kuyeka ukudlulisela ngelixa umbane wangoku wefilimu / i-Agglomerator idlula ixabiso.

■ I-CORDURT YENKQUBO YOKUGQIBELA / UMGANGATHO WOKUGQIBELA

■ Isantya sokuphumelela sisengqiqweni sinokutshintsha (ngokwesiseko sezinto ezibonakalayo)

■ Isantya se-Pelletise sinokutshintsha (ngokwemveliso yokuphuma kunye nobungakanani)