I-Infrared Rotary Dryer yokwenza i-PET Fiber

Iinkcukacha zeMveliso

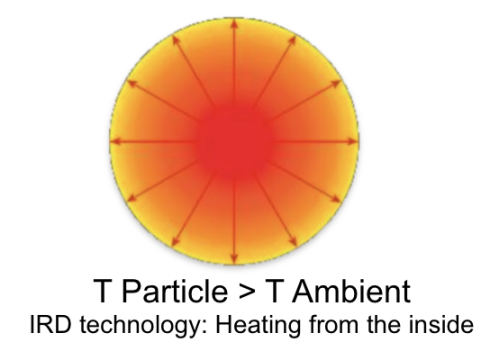

Imisebe ye-infrared engena kwaye ibonakalisa kwizinto eziphathekayo ayichaphazeli umbutho wezinto eziphathekayo, kodwa izicubu ezithintekayo ziya kuguqulwa zibe amandla okushisa ngenxa yokutshatyalaliswa kwe-molecular, okubangela ukuba ukushisa kwezinto kuphakame ngokukhawuleza.

Ubushushu ukuya embindini. Ngokusebenzisa ukukhanya okufutshane kwe-infrared i-infrared material ifudunyezwa ngokuthe ngqo ngaphakathi

Ukusuka Ngaphakathi ukuya ngaphandle. Amandla kwi-core atshisa izinto ezivela kwi

ngaphakathi ngaphandle, ngoko umswakama uqhutyelwa ngaphakathi ukuya ngaphandle kwezinto eziphathekayo.

Ukufuma kokufuma.Ukujikeleza komoya okongeziweyo ngaphakathi kwesomisi kususa umswakama owenziwe ngumphunga kwizinto eziphathekayo.

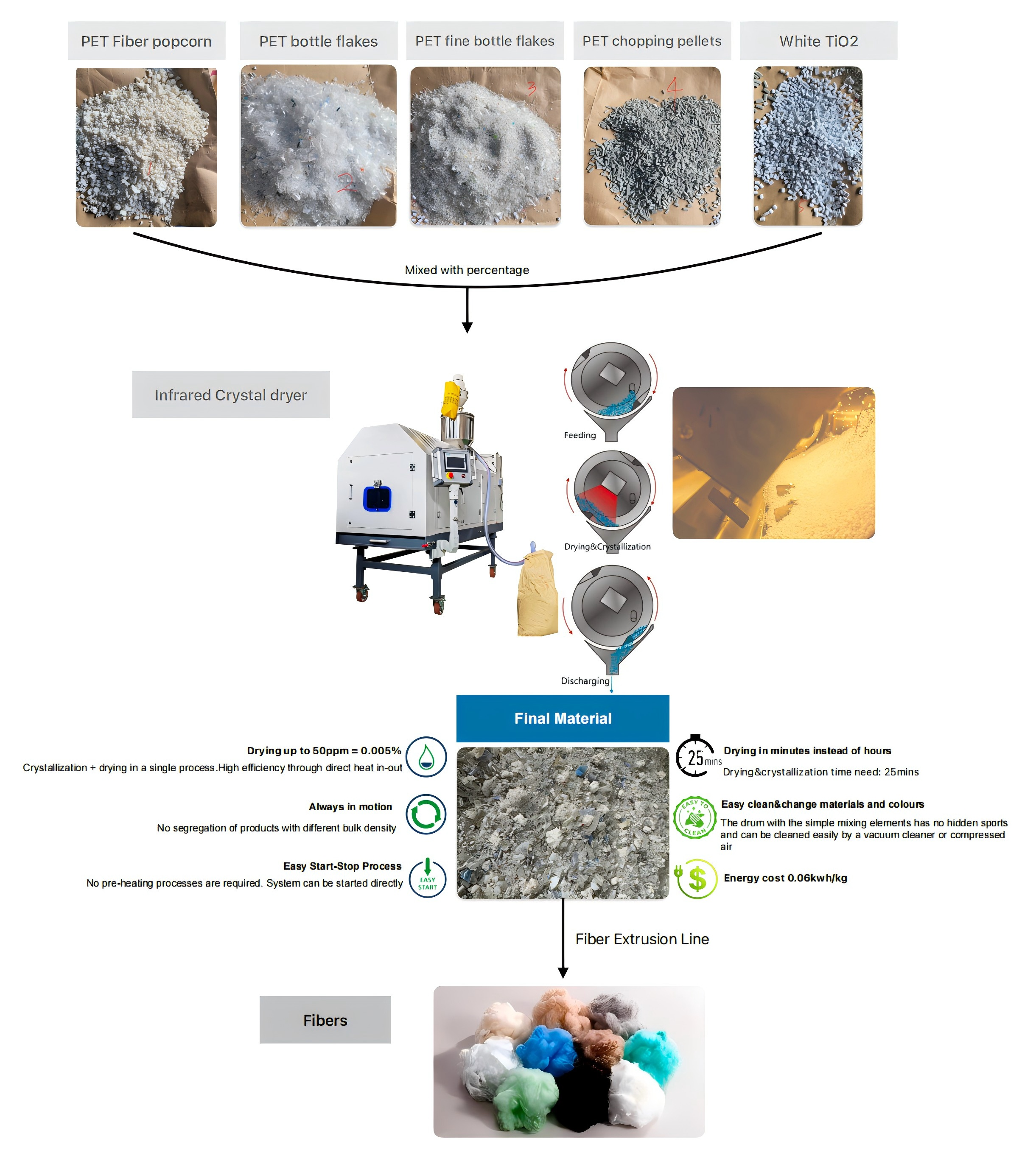

Into yokuphonononga

Ukuqhubekeka kubonisiwe

I-advanteji into esiyenzayo ekuqhubeni

①Ukuqalisa ngoko nangoko kunye nokuvala ngokukhawuleza

→Isiqalo esikhawulezileyo sokwenziwa kwemveliso sinokwenzeka.Isigaba sokufudumala somatshini asifunwa

→Ukuqhuba kunokuqaliswa, kumiswe kwaye kuqalwe ngokutsha ngokulula

② Isoloko ikwintshukumo

→Akukho kwahlulwa kweemveliso ezinobuninzi obahlukeneyo

→Ujikelezo lweperment lwegubu lugcina imathiriyeli ihamba kwaye ukudityaniswa kunokuphetshwa

③ Ukomisa ngemizuzu endaweni yeeyure (Ukomisa kunye nesidingo sexesha lekristale: 25mins)

→Imitha ye-infrared ibangele i-molecular thermal pscillations esebenza ngokuthe ngqo kumbindi wamasuntswana angaphakathi ngaphandle. ukuze ukufuma okungaphakathi kwamasuntswana kufudunyezwe ngokukhawuleza kwaye kube ngumphunga kumoya ojikelezayo ojikelezayo, kwaye ubumanzi bususwe ngaxeshanye.

④ Ukuphucula ukuphuma kwePET Extruder

→ Ukonyuka koxinzelelo lwesambuku nge-10-20% kunokufezekiswa kwinkqubo ye-IRD, phucula uqinisekiso lwefidi kwindawo yokungena e-extruder kakhulu, ngelixa isantya se-extruder sihlala singatshintshi, kukho ukuphucuka kakhulu kokuzaliswa kokusebenza kwisikrufu.

⑤ Ukucoca ngokulula&tshintsha imathiriyeli kunye nemibala

→ Igubu elinezinto ezilula zokuxuba alinayo imidlalo efihliweyo kwaye inokucocwa ngokulula ngesicoci sevacuum okanye umoya ocinezelweyo.

⑥ Ixabiso lamandla 0.06kwh/kg

→ amaxesha amafutshane okuhlala = inkqubo ephezulu yokuguquguquka

→ amandla alungelelaniswe ngabanye --- Isibane ngasinye sinokulawulwa yinkqubo yePLC

FAQ

a.Uthini umda wokufuma kwe-intial yemathiriyeli ekrwada?

→ Akukho mda uchanekileyo kumanzi okuqala, i-2%, 4% zombini zilungile

b. Ngowuphi ukufuma kokugqibela onokukufumana emva komiswa?

→ ≦30ppm

c.Yintoni imfuneko yokomisa&ikristale?

→ 25-30mins. Ukomisa kunye nokuqaqambisa kuya kugqitywa kwinqanaba elinye

d.Ngowuphi umthombo wokufudumeza? Indawo ephantsi yombethe umoya owomileyo?

→ Sisebenzisa izibane ze-infrared (amaza e-infrared) njengomthombo wokufudumeza. Ngokukhanya kwe-infrared ngamaza amafutshane izinto zifudunyezwa ngokuthe ngqo ukusuka ngaphakathi ukuya ngaphandle. Amandla kwi-core atshisa izinto ezivela ngaphakathi, ngoko umswakama uqhutyelwa ngaphakathi ukuya ngaphandle kwezinto .

e. Ingaba imathiriyeli yoxinaniso eyahluka-hlukileyo iyakubekwa ngokuqinisekisa ukomiswa?

→ Ukujikeleziswa kweperment yegubu kugcina imathiriyeli ihamba,--Akukho lucalucalulo lwemathiriyeli enoxinaniso oluninzi olwahlukileyo ngelixa isoyiswa kwi-extruder.

f. Lithini iqondo lobushushu lokomisa?

→ Iqondo lobushushu lokumisa umda wesethi: 25-300℃. Njenge-PET, sicebisa ukuba samkele malunga ne-160-180℃

g. Ngaba kulula ukutshintsha i-masterbatch yombala?

→Igubu elinezinto ezilula zokuxuba alinamdlalo ofihlakeleyo, kulula ukutshintsha imathiriyeli okanye ibhetshi yombala

h.Uhlangabezana njani nomgubo?

→ Sinento yokususa uthuli eya kusebenza kunye ne-IRD kunye

I. Buyintoni ubomi bokukhanya kwezibane?

→ 5000-7000hours. (Ayithethi ukuba izibane azinakuphinda zisebenze, kuphela ukuthomalalisa amandla

J. Ngubani ixesha lokuziswa?

→ iintsuku zokusebenza ezingama-40 emva kokufumana idiphozithi

ukuba uneenkcukacha ezithe vetshe ongathanda ukuzazi, nceda usithumelele i-imeyile:

Ukubaleka kwireferensi yefektri yabathengi

Inkonzo yethu

Umzi-mveliso wethu uneZiko loVavanyo. Kwiziko lethu loVavanyo, sinokwenza umfuniselo oqhubekayo okanye oyekiweyo wemathiriyeli yesampulu yabathengi. Izixhobo zethu zibonelelwe ngetekhnoloji ebanzi yokuzenzekela kunye nokulinganisa.

- Singabonisa --- Ukuhambisa / ukuLayisha, Ukomisa & Crystallization, Ukukhupha.

- Ukomisa kunye ne-crystallization yezinto eziphathekayo ukumisela ukufuma okushiyekileyo, ixesha lokuhlala, igalelo lamandla kunye nezinto eziphathekayo.

- Singakwazi kwakhona ukubonisa intsebenzo ngokukhupha iibhetshi ezincinci.

- Ngokuhambelana neemfuno zakho zemathiriyeli kunye nemveliso, sinokwenza imephu yesicwangciso kunye nawe.

Injineli enamava iya kwenza uvavanyo. Abasebenzi bakho bayamenywa ukuba bathathe inxaxheba kwiindlela zethu ezidibeneyo. Ke ngoko ninako kokubini ukuba negalelo elibonakalayo kunye nethuba lokubona iimveliso zethu zisebenza.