I-PET Bottle Flake Granulation Line

Ibhotile ye-PET iRecycling Pelletizer PET Granulation Machine Process flow

Isixhobo sokufunxa → Isixhobo sokucoca ngekristale esinefrared→ Ivacuum dis-charger → isikrufu esinye isijija →Isixhobo sokutshintshisa isikrini sehydraulic→ Intloko yokupholisa amanzi →isitya sokugungxulwa samanzi →Ipelletizer yokugungxula amanzi →umatshini wokunkcenkceshela→umatshini wokuhlunguza →Umatshini wokungcangcazela →Imveliso egqityiweyo yokupakisha.

Inkcazo yobuGcisa

|

Igama lomatshini |

I-PET Single Screw Extrusion Pelletizing Line |

|

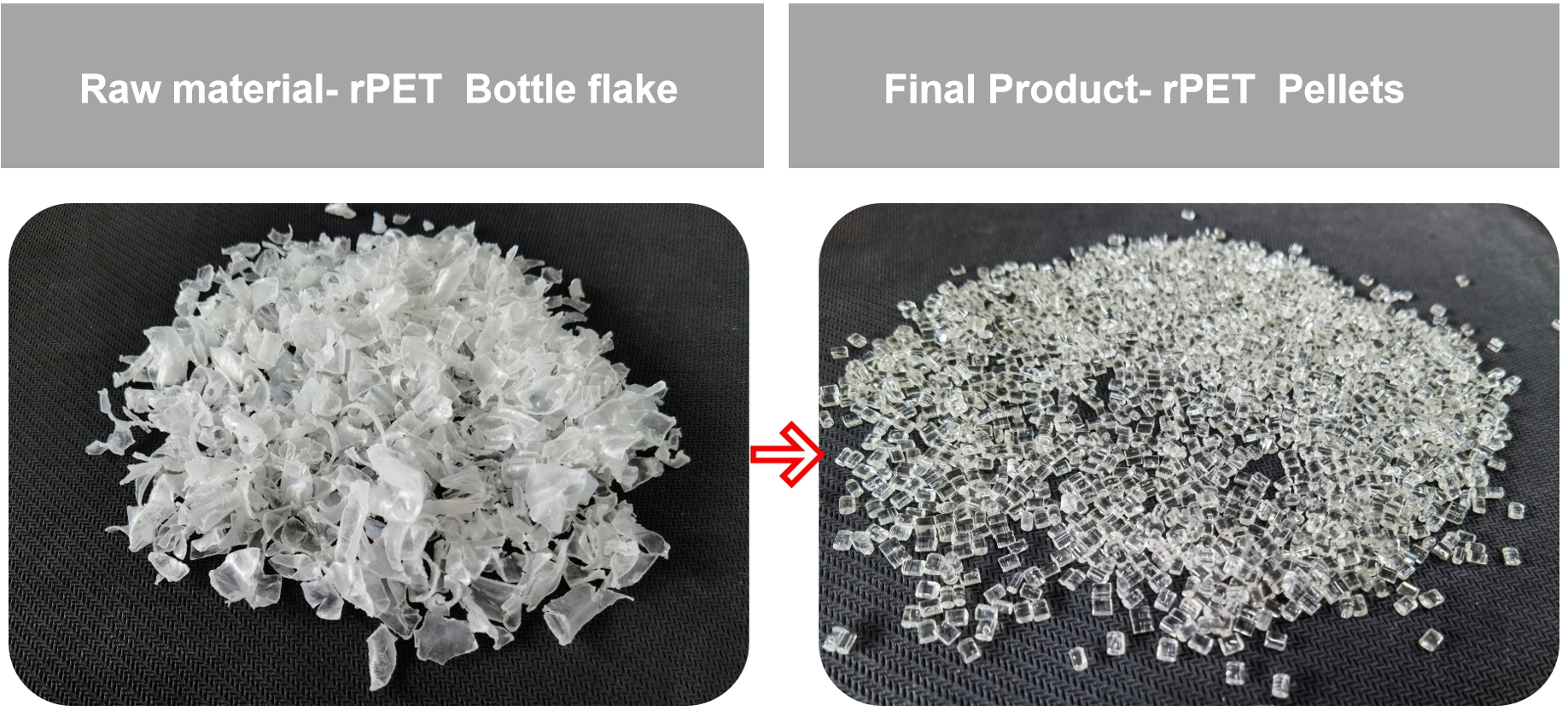

Impahla engekasilwa |

IiFlakes ze-rPET |

|

Imveliso yokugqibela |

IiPellet ze-rPET |

|

Amacandelo Line Production | Inkqubo yokomisa ikristale ene-infrared: Ivacuum feeder/ I-infrared crystal dryer/ Isitshizi sevacuum

Umgca wokukrazula oMnye we-Screw Extrusion: Isikrufu esinye esikhulu esikhuphayo/I-Hydraulic Double Pistons yokutshintsha isikrini/Intloko Die/Izikhonkwane zamanzi ezigungxulwayo/Ipellitizer egungxulwayo/Umatshini wokukhupha amanzi ngokuthe nkqo/Umatshini wokungcangcazela/Ugcino

|

|

I-Screw diameter |

90mm-150mm |

|

L/D |

1:24/1:30 |

|

Uluhlu lwemveliso |

150-1000KG/H |

|

Izinto zokukrola |

38CrMoAlA ngoNyango lwe-Nitrding |

|

Uhlobo lwePelletizing |

Ukugungxulwa kwamanzi kunye ne-pelletizing |

|

Umtshintshi wesikrini |

Hydraulic Double Pistons Screen Tshintsho |

Iinkcukacha zoomatshini

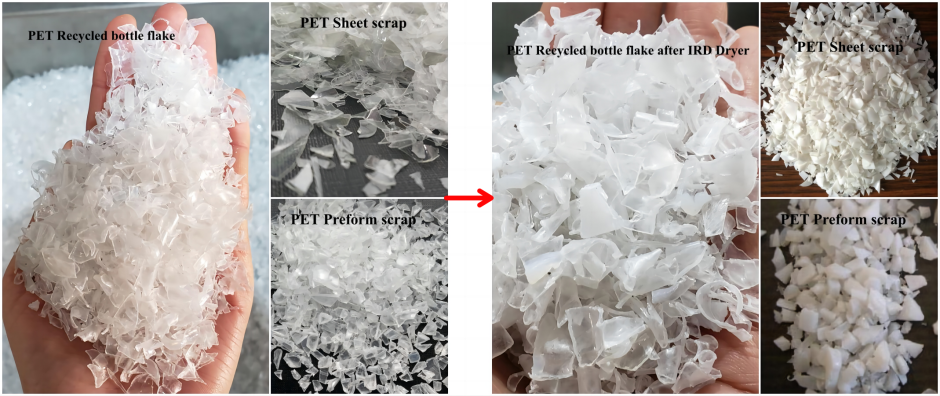

I-Infrared Crystal Dryer (LIANDA PATENT DESIGN)

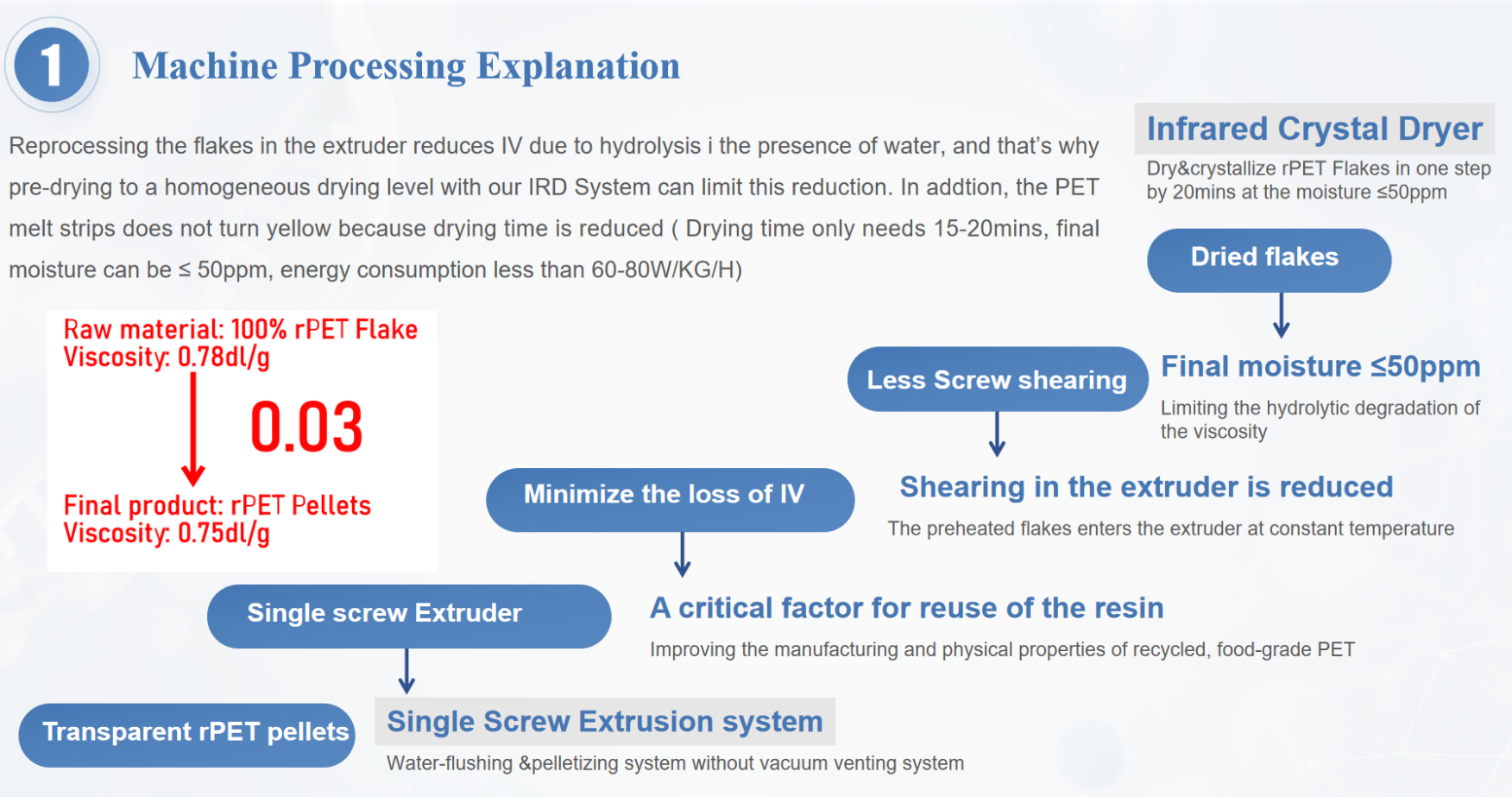

① Ukuphucula ukwenziwa kunye neepropathi ezibonakalayo ze-recycled, ibakala lokutya le-PET ngokusebenzisa itekhnoloji enikwa amandla ngamaza e-infrared inendima ebalulekileyo yokudlala kwipropathi ye-intrinsic viscosity (IV)

②I-crystallization yangaphambili kunye nokomiswa kweeflakes ngaphambi kokukhutshwa kunceda ukunciphisa ilahleko ye-IV kwi-PET, into ebalulekileyo ekusetyenzisweni kwakhona kwe-resin.

③Ukusetyenzwa kwakhona kweeflakes kwi-extruder kunciphisa i-IV ngenxa ye-hydrolysis kubukho bamanzi, kwaye yiyo loo nto ukomisa kwangaphambili ukuya kwinqanaba lokumisa elilinganayo ngeNkqubo yethu ye-IRD kunokunciphisa oku kuncitshiswa.

Ukongezelela, i-PET melt strips ayijiki iphuzi kuba ixesha lokumisa liyancipha (Ixesha lokumisa lifuna kuphela i-15-20mins, umswakama wokugqibela unokuba ≤ 30ppm, ukusetyenziswa kwamandla ngaphantsi kwe-60-80W / KG / H)

④Ukucheba kwi-extruder kukwancitshiswa ngenxa yokuba izinto ezifudunyeziweyo zingena kwi-extruder kwiqondo lobushushu eliqhubekayo "

⑤Ukuphucula imveliso yePET Extruder

Ukunyuka kobuninzi be-bulk density nge-10 ukuya kwi-20 % kunokufezekiswa kwi-IRD, kuphucula ukusebenza kwesondlo kwindawo yokungena e-extruder kakhulu - ngelixa isantya se-extruder sihlala singatshintshi, kukho ukuphuculwa kakhulu kokuzaliswa kokusebenza kwi-screw.

Umgca wokuPelletizing weScrew Extrusion omnye (Ngaphandle kokuVunyelwa kweVacuum)

Ukusebenzisa amandla e-Single screw extruder kunye nokudibanisa kunye ne-LIANDA eyilwe ngokukodwa isikhonkwane se-rPET Bottle flakes, siye sakwazi ukwandisa umthamo nge-20% ngamandla amancinci asetyenzisiweyo xa kuthelekiswa ne-Parallel double screw extruder.

I-Viscosity yeepellets ze-rPET eziveliswa yinkqubo yethu: kukho kuphela ≤0.02-0.03dl / g i-viscosity drop ---ngaphandle kokongeza nayiphi na i-viscosity enhancer. (Ngokovavanyo lwethu lwangaphakathi)

rPET pellets Umbala: transparent --- ngaphandle kokongeza nasiphi na isixhasi elubala

Ngaphandle kwenkqubo yokukhupha iVacuum --- Ukugcina iindleko zamandla, umsebenzi ongenazingxaki kunye nozinzo

Iifoto zoomatshini