I-PET Flake / i-scrap dehumidifier crystallizer

Isampulu yosetyenziso

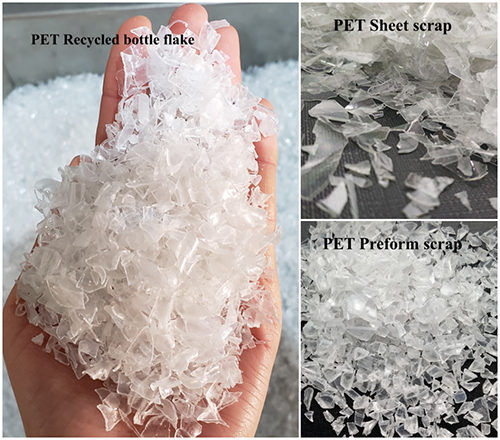

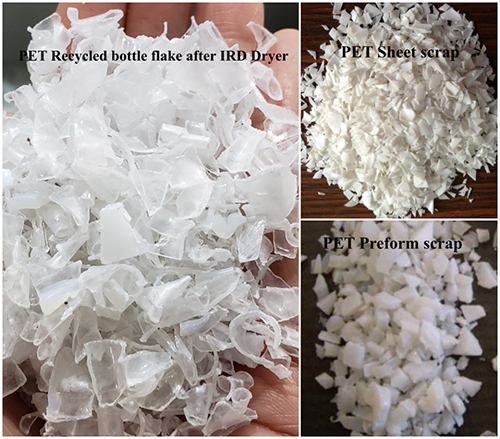

| Impahla engekasilwa | I-PET Recycled flake/ PET sheet scrap/PET Preform scrap |

|

| Ukusebenzisa uMtshini | LDHW-600*1000 |  |

| Ukomisa & Iseti yoBubushushu obukhazimlisiweyo | I-180-200℃Inokulungelelaniswa ngepropathi ye-rawmaterial | |

| Ixesha lekristali limisiwe | 20mins | |

| Izinto zokugqibela | I-Crystallized kunye neyomileyo ye-PET izilahlwa kunyeukufuma kokugqibela kunokuba malunga ne-30ppm |  |

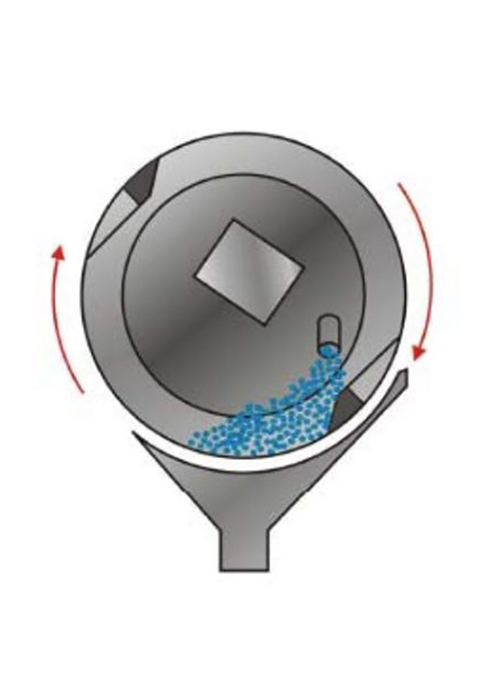

Indlela Yokusebenza

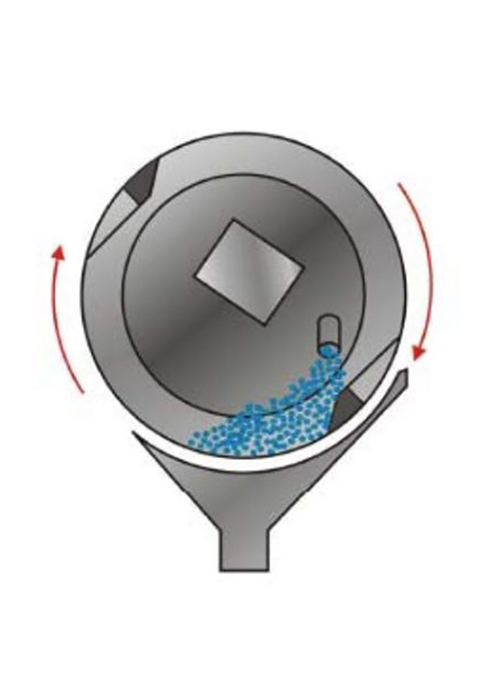

Ukutya/Ukulayisha

Ukomisa & Crystallization Processing

Ukukhupha

>> Kwinqanaba lokuqala, ekujoliswe kuko kuphela kukufudumeza imathiriyeli ukuya kubushushu obusetwe kwangaphambili.

Yamkela isantya esicothayo somgqomo ojikelezayo, izibane ze-infrared zesomisi ziya kuba kumgangatho ophezulu, emva koko iipellets ze-PET ziya kuba nokufudumeza okukhawulezayo de iqondo lobushushu linyuke liye kubushushu obusetwe kwangaphambili.

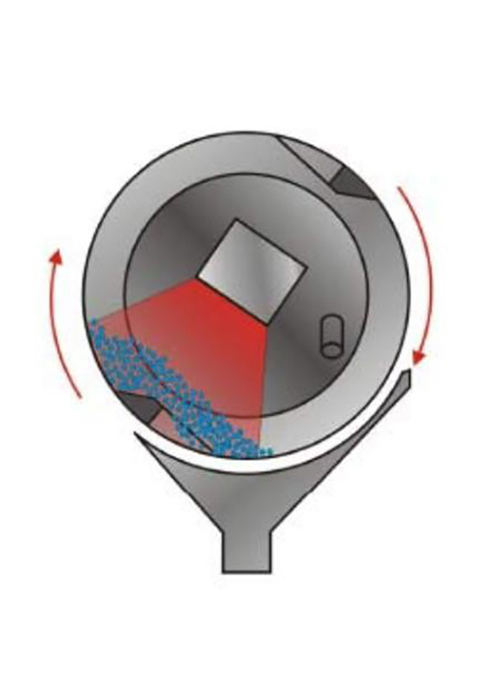

>> Ukomisa kunye nenyathelo lokuqaqambisa

Emva kokuba izinto zifike kwiqondo lokushisa, isantya somgqomo siya kwandiswa ukuya kwisantya esiphezulu esijikelezayo ukuphepha ukudibanisa kwezinto. Ngexesha elifanayo, izibane ze-infrared ziya kwandiswa kwakhona ukugqiba ukomisa. Emva koko isantya sokujikeleza igubu siya kuthotywa kwakhona. Ngokuqhelekileyo inkqubo yokumisa iya kugqitywa emva kwe-15-20mins. (Ixesha elichanekileyo lixhomekeke kwipropati yezinto)

>> Emva kokugqiba inkqubo yokomisa, i-IR Drum iya kukhupha ngokuzenzekelayo izinto kwaye iphinde igcwalise idrum kumjikelo olandelayo.

Ukuzaliswa ngokuzenzekelayo kunye nazo zonke iiparitha ezifanelekileyo kwiirampu ezihlukeneyo zokushisa zihlanganiswe ngokupheleleyo kwi-state-of-art yolawulo lwe-Touch Screen. Nje ukuba iiparamitha kunye neeprofayili zobushushu zifunyenwe kwizinto ezithile, iisetingi zeethisisi zinokugcinwa njengeendlela zokupheka kwinkqubo yolawulo.

Inzuzo Yethu

Ngokuqhelekileyo i-PET Bottle flakes okanye i-sheet scrap enezinga lokuqala lokufuma ukuya kwi-10000-13000ppm. I-PET Bottle flakes okanye i-sheet scrap (iNtombikazi okanye ixutywe) iya kuphinda ifakwe kwi-Infrared crystal dryer kwi-20mins, iqondo lokushisa lokumisa liya kuba yi-150-180 ℃ kwaye lomiswe ukuya kwi-50-70ppm, emva koko lityiswe kwi-Single screw extruding system ukuze kuqhutywe ngakumbi.

● Ukunciphisa ukuthotywa kwe-hydrolytic ye-viscosity.

● Thintela ukunyuka kwamanqanaba e-AA kwizinto ezidibene nokutya

● Ukwandisa umthamo wemveliso ukuya kwi-50%

● Uphuculo kwaye wenze umgangatho wemveliso uzinze-- Ukulingana kunye nesiqulatho sokufuma esiphindaphindwayo semathiriyeli

● Ukuya kuthi ga kwi-60% ngaphantsi kokusetyenziswa kwamandla kunenkqubo eqhelekileyo yokomisa

● Akukho kucalulwa kweemveliso ezinobuninzi obahlukeneyo

● Ubushushu obuzimeleyo kunye nexesha lokumisa libekwe

● Ukucoca ngokulula kunye nokutshintsha izinto

● Ukuqalisa ngokukhawuleza kunye nokuvalwa ngokukhawuleza

● Ukwenziwa kweekristale ezifanayo

● Akukho iipellet ezidityanisiweyo kunye nokuncamathela

● Ukunyamekela izinto eziphathekayo

Itheyibhile yokuthelekisa

| Into | I-IRD Dryer | Isomisi esiqhelekileyo |

| Ukudlulisa okuphakathi | Akukho nanye | Umoya oshushu |

| Ukutshintshwa kobushushu | Zombini ngaphakathi nangaphandle amasuntswana kunye. | Ukusuka ngaphandle ukuya ngaphakathi ngamasuntswana kancinci kancinci. |

| Amandla | Gcina ubuncinci be-20 ~ 50% amandla xa kuthelekiswa nesomisi semveli. | Yitya amandla amaninzi. |

| Ixesha lenkqubo | 1. ICrystallization kunye nokomisa: Zicutshungulwa ngaxeshanye ngaphakathi malunga ne-8 ~ 15 imizuzu. 2. Ukomisa kunye necrystallization ngexesha | 1. ICrystallization: Malunga ne-30 ~ 60 imizuzu. 2. Ukomisa: Malunga ne-4 ~ 6 iiyure. |

| Isiqulatho sokufuma | 1. Ngaphantsi kwe-50-70 PPM emva kwe-IRD iqhutywe. | 1. Chitha i-30 ~ 60 imizuzu yokutshintsha i-amorphous PET ukuya kwi-crystallized PET kuqala. 2. Ngaphantsi kwe-200PPM emva kweeyure ezi-4 zokususa humidifier kusetyenzwe. 3. Ngaphantsi kwe-50 PPM emva kweeyure ezingaphezulu kwe-6 dehumidifier esetyenzisiweyo. |

| Ixesha lokukhokhela | 20mins | Ngaphezu kweeyure ezi-6. |

| Ukutshintsha kwezinto | 1. Kulula kwaye ngokukhawuleza. 2. Kukho kuphela 1 ~ 1.5 amaxesha umthamo wemathiriyeli yokusetyenziswa ngeyure kwi-buffer hopper. | 1. Kunzima kwaye kancinci. 2. Kukho amaxesha angama-5 ~ 7 amandla okusetyenziswa kwemathiriyeli ngeyure kwicrystallizer & hopper. |

| Ukusebenza | Elula--- Ngulawulo lwe-Siemens PLC

| Kunzima njengoko kufuneka ibeke i-PET encinci yekristali kwikristali xa iqala ukusebenza. |

| Isondlo | 1. Elula. 2. Iindleko zokulungisa ezisezantsi. | 1. Kunzima. 2. Iindleko eziphezulu zokugcina. |

Iifoto zoomatshini

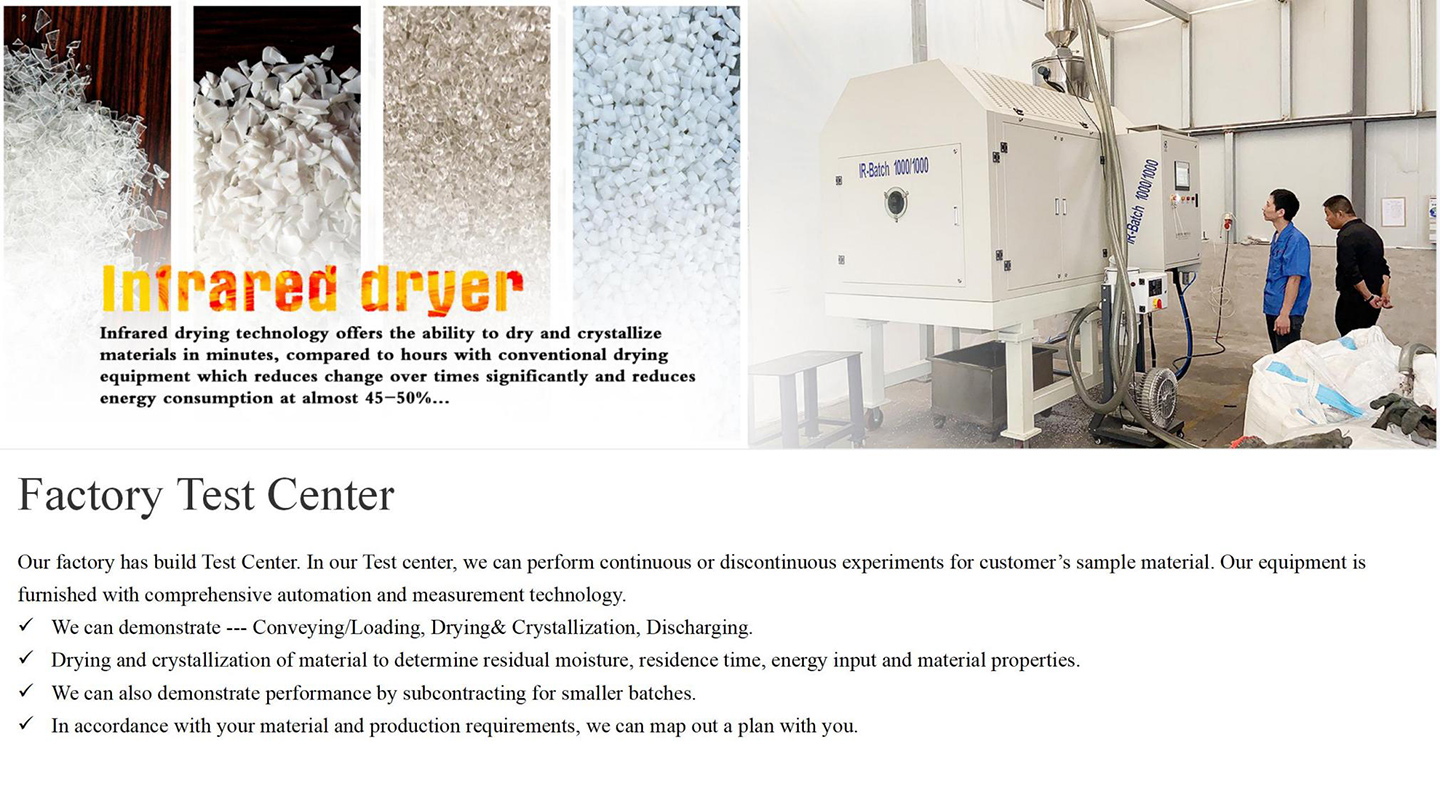

Uvavanyo lweMathiriyeli lwasimahla

Injineli enamava iya kwenza uvavanyo. Abasebenzi bakho bayamenywa ukuba bathathe inxaxheba kwiindlela zethu ezidibeneyo. Ke ngoko ninako kokubini ukuba negalelo elibonakalayo kunye nethuba lokubona iimveliso zethu zisebenza.

Ukufakwa komatshini

>> Nikeza ngeNjineli enamava kumzi-mveliso wakho ukunceda ufakelo kunye novavanyo lwezinto eziphathekayo

>> Yamkela iplagi yendiza, akukho mfuneko yokudibanisa ucingo lombane ngelixa umthengi efumana umatshini kumzi-mveliso wakhe. Ukwenza lula inyathelo lofakelo

>> Nikeza ividiyo yokusebenza yofakelo kunye nesikhokelo esisebenzayo

>> Inkxaso kwinkonzo yomgca