Iplastiki ye-resin dryer

Isampulu yosetyenziso

| Impahla engekasilwa | I-PET Resin CR-BrightFor iphakheji yokutya |  |

| Ukusebenzisa uMtshini | LDHW-600*1000 |  |

| Ukufuma kokuqala | 2210ppmIvavanywe nguGerman Sartorius isixhobo sovavanyo lokufuma |  |

| Ukomisa Ubushushu iseti | 200℃ | |

| Ixesha lokumisa libekiwe | 20mins | |

| Ukufuma kokugqibela | 20ppmIvavanywe nguGerman Sartorius isixhobo sovavanyo lokufuma |  |

| Imveliso yokugqibela | I-PET Resin eyomileyo akukho clumping, akukho pellets ezincamathelayo |  |

Indlela Yokusebenza

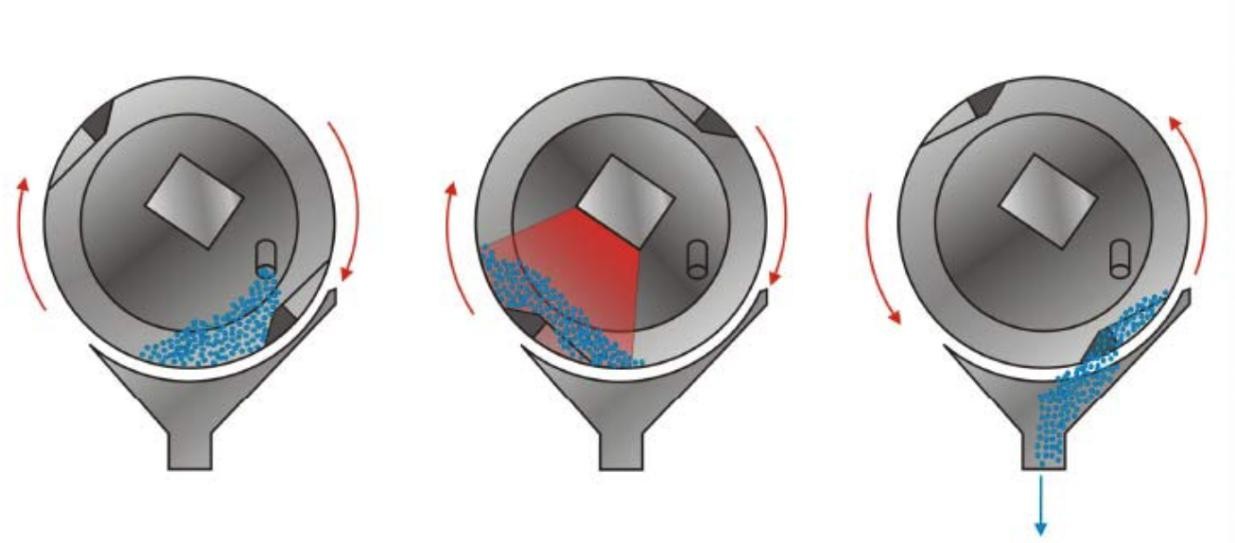

>> Kwinqanaba lokuqala, ekujoliswe kuko kuphela kukufudumeza imathiriyeli ukuya kubushushu obusetwe kwangaphambili.

Yamkela isantya esicothayo somgqomo ojikelezayo, izibane ze-infrared zesomisi ziya kuba kumgangatho ophezulu, emva koko iipellets ze-PET ziya kuba nokufudumeza okukhawulezayo de iqondo lobushushu linyuke liye kubushushu obusetwe kwangaphambili.

>> Ukomisa inyathelo

Emva kokuba izinto zifike kwiqondo lokushisa, isantya somgqomo siya kwandiswa ukuya kwisantya esiphezulu esijikelezayo ukuphepha ukudibanisa kwezinto. Ngexesha elifanayo, izibane ze-infrared ziya kwandiswa kwakhona ukugqiba ukomisa. Emva koko isantya sokujikeleza igubu siya kuthotywa kwakhona. Ngokuqhelekileyo inkqubo yokumisa iya kugqitywa emva kwe-15-20mins. (Ixesha elichanekileyo lixhomekeke kwipropati yezinto)

>> Emva kokugqiba inkqubo yokomisa, i-IR Drum iya kukhupha ngokuzenzekelayo izinto kwaye iphinde igcwalise idrum kumjikelo olandelayo.

Ukuzaliswa ngokuzenzekelayo kunye nazo zonke iiparitha ezifanelekileyo kwiirampu ezihlukeneyo zokushisa zihlanganiswe ngokupheleleyo kwi-state-of-art yolawulo lwe-Touch Screen. Nje ukuba iiparamitha kunye neeprofayili zobushushu zifunyenwe kwizinto ezithile, iisetingi zeethisisi zinokugcinwa njengeendlela zokupheka kwinkqubo yolawulo.

Inzuzo Yethu

| 1 | Ukusetyenziswa kwamandla aphantsi | Ukusetyenziswa kwamandla aphantsi kakhulu xa kuthelekiswa neenkqubo eziqhelekileyo, ngokuziswa ngokuthe ngqo kwamandla e-infrared kwimveliso. | |

| 2 | Imizuzu endaweni yeeyure | Imveliso ihlala imizuzu embalwa kuphela kwinkqubo yokomisa kwaye iyafumaneka kumanyathelo angaphezulu okuvelisa. | |

| 3 | Ngoko nangoko | Ukuqhuba kwemveliso kunokuqalisa ngoko nangoko xa kuqalwa. Isigaba sokufudumala somatshini asifunwa. | |

| 4 | Ngobulali | Izinto eziphathekayo zifudumala ngobumnene ukusuka ngaphakathi ukuya ngaphandle kwaye azilayishwanga ngaphandle kweeyure ngokushisa, kwaye mhlawumbi zonakaliswe. | |

| 5 | Kwinqanaba elinye | I-Crystallization kunye nokumisa kwinqanaba elinye | |

| 6 | Ukonyuka kokwenziwa komsebenzi | Ukonyuka kokutyalwa kwezityalo ngokunciphisa umthwalo kwi-extruder | |

| 7 | Akukho kubambana, akukho kuncamathela | Ukujikeleza kwegubu kuqinisekisa ukuhamba rhoqo kwezinto eziphathekayo.Iikhoyili ezijikelezayo kunye nezinto ezixutywayo ezilungiselelwe imveliso yakho ziqinisekisa umxube ofanelekileyo wezinto eziphathekayo kwaye ugweme ukugoba. Imveliso ishushu ngokulinganayo | |

| 8 | Ulawulo lwe-Siemens PLC | Ulawulo.Idatha yenkqubo, njengezinto eziphathekayo kunye nokukhupha ukushisa komoya okanye amanqanaba okugcwalisa ahlala ebekwe esweni ngokusebenzisa abenzi boluvo kunye neepyrometers. Ukuphambuka kubangela ukulungelelaniswa okuzenzekelayo.Ukuveliswa kwakhona.Iindlela zokupheka kunye neeparitha zenkqubo zingagcinwa kwinkqubo yokulawula ukuqinisekisa iziphumo ezifanelekileyo kunye nokuveliswa kwakhona.Ukugcinwa okude.Inkonzo ye-intanethi ngemodem. | |

| 9 | Ixesha lokumisa lifuna kuphela i-20mins, ukufuma kokugqibela kunokuba ≤ 30ppm | Imisebe ye-infrared engena kwaye ibonakalisa kwizinto eziphathekayo ayichaphazeli umbutho wezinto eziphathekayo, kodwa izicubu ezithintekayo ziya kuguqulwa zibe amandla okushisa ngenxa yokutshatyalaliswa kwe-molecular, okubangela ukuba ukushisa kwezinto kuphakame. | |

| 10 | Akukho kubambana, akukho kuncamathela | Ukujikeleza kwegubu kuqinisekisa ukuhamba rhoqo kwezinto eziphathekayo.Iikhoyili ezijikelezayo kunye nezinto ezixutywayo ezilungiselelwe imveliso yakho ziqinisekisa umxube ofanelekileyo wezinto eziphathekayo kwaye ugweme ukugoba. Imveliso ishushu ngokulinganayo | |

| 11 | Ukucoca ngokulula kunye nokutshintsha izinto | Ukufikelela kakuhle kuwo onke amacandelo kuvumela ukucoceka okulula nokukhawulezayo.Ukutshintsha kwemveliso ngokukhawuleza. | |

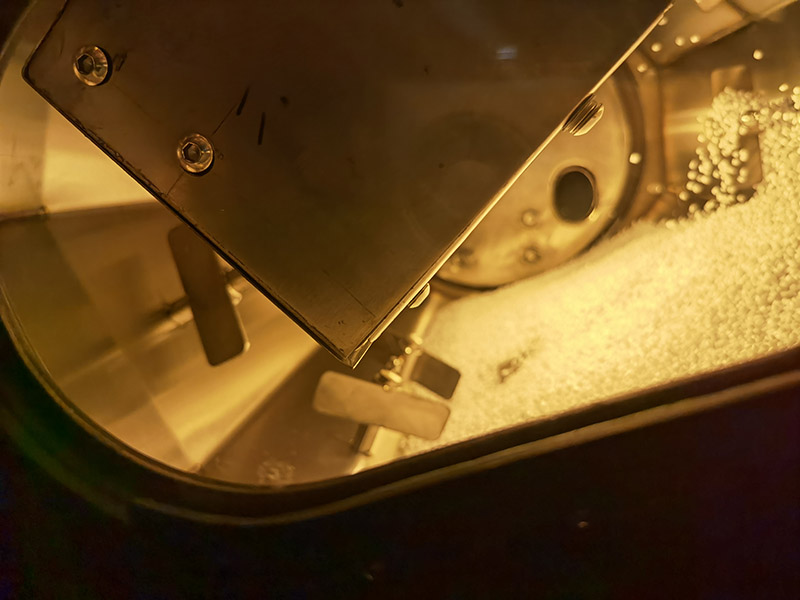

Iifoto zoomatshini

Ukusetyenziswa komatshini

Ukomisa Ukomiswa kweegranulate zeplastiki ( PET, TPE, PETG, APET, RPET, PBT, ABS/PC, HDPE, LCP, PC, PP, PVB, WPC, TPU njl njl) kunye nezinye imathiriyeli ezininzi ezihamba simahla.

ICrystallization PET (iBottle flakesm granulates, sheet scrap), PET Masterbatch, CO-PET, PBT,PEEK, PLA, PPS njl.

Iintlobo ezahlukeneyo ze-Thermal zicutshungulwa ukususwa kwe-oligomeren yokuphumla kunye nezinto eziguquguqukayo

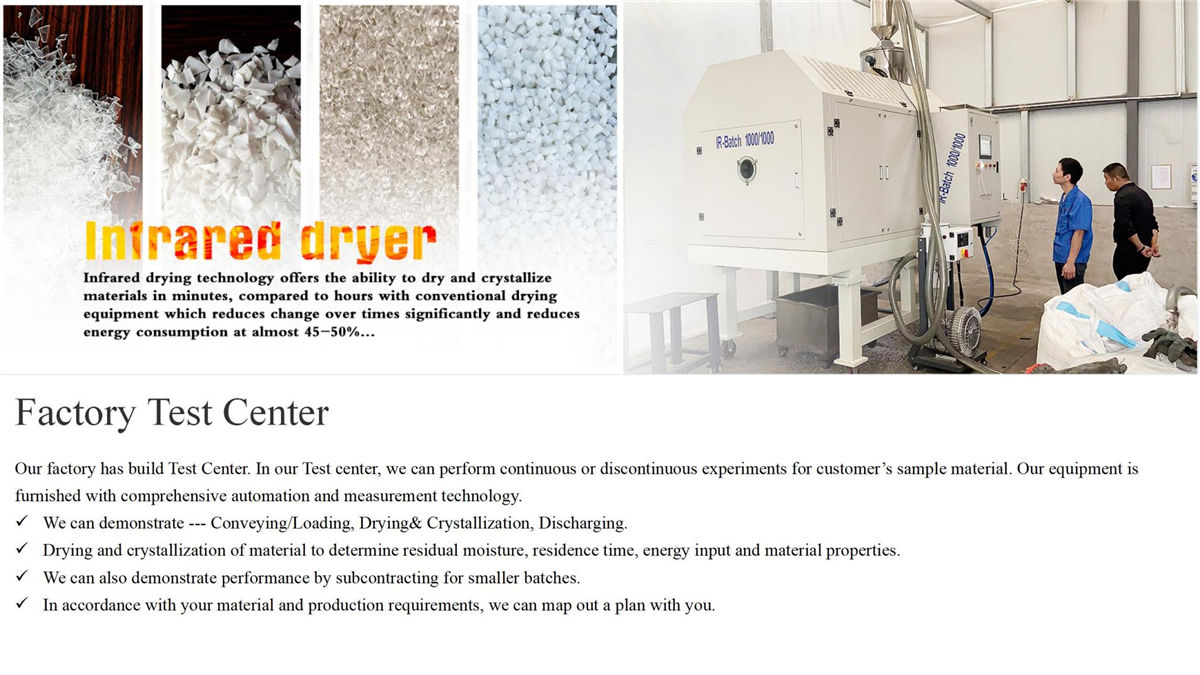

Uvavanyo lweMathiriyeli lwasimahla

Injineli enamava iya kwenza uvavanyo. Abasebenzi bakho bayamenywa ukuba bathathe inxaxheba kwiindlela zethu ezidibeneyo. Ke ngoko ninako kokubini ukuba negalelo elibonakalayo kunye nethuba lokubona iimveliso zethu zisebenza.

Ukufakwa komatshini

>> Nikeza ngeNjineli enamava kumzi-mveliso wakho ukunceda ufakelo kunye novavanyo lwezinto eziphathekayo

>> Yamkela iplagi yendiza, akukho mfuneko yokudibanisa ucingo lombane ngelixa umthengi efumana umatshini kumzi-mveliso wakhe. Ukwenza lula inyathelo lofakelo

>> Nikeza ividiyo yokusebenza yofakelo kunye nesikhokelo esisebenzayo

>> Inkxaso kwinkonzo yomgca