PLA PET thermoforming Sheet extrusion line

I-infrared crystal dryer+ i-PET Sheet Extrusion line

I-Advantage siyenzayo

>> LIANDA iphuhlisaUmgca omnye we-screw extrusion one-infrared crystal dryerkwiphepha le-PET, i-20mins yangaphambili yokumisa kunye ne-crystallization, umswakama wokugqibela unokuba ngu-≤50ppm (umatshini womatshini Sebenza ngokuzinzileyo, umgangatho wephepha lokugqibela uzinzile)

Umgca we-extrusion uneempawu zokusetyenziswa kwamandla aphantsi, inkqubo yokuvelisa elula kunye nokugcinwa lula.

Isakhiwo se-screw esicandiweyo sinokunciphisa ilahleko ye-viscosity ye-PET resin, i-symmetrical kunye ne-thith-wall-wall calender roll iphucula umphumo wokupholisa, umthamo kunye nomgangatho weshidi.

I-Mult-components dosing feeder ilawula ipesenti yezinto ezintsha, imathiriyeli yokurisayikilisha kunye nebhetshi enkulu ngokuchanekileyo,.

Iphepha lisetyenziswe ngokubanzi kushishino lokupakisha lwe-thermoforming.

>>Infrared crystal dryer -----Dry &Crystallize R-PET flakes/chips in 20mins at 30ppm ngokugcina i-45-50% yeendleko zamandla.

※Ukunciphisa ukuthotywa kwe-hydrolytic ye-viscosity.

※ Thintela ukunyuka kwamanqanaba e-AA kwizinto ezinoqhagamshelwano lokutya

※ Ukwandisa umthamo wemveliso ukuya kwi-50%

※ Uphuculo kwaye wenze umgangatho wemveliso uzinze-- Ukulingana kunye nokuphindaphinda umxholo wokufuma wesixhobo

Ukunciphisa iindleko zokwenziwa kwephepha le-PET: Ukuya kuthi ga kwi-60% ngaphantsi kokusetyenziswa kwamandla kunenkqubo eqhelekileyo yokomisa

Ukuqalisa kwangoko kunye nokuvala ngokukhawuleza --- Akukho mfuneko yokufudumeza kwangaphambili

Ukomisa & crystallization kuya kuqwalaselwa kwinyathelo elinye

Ukuphucula amandla e-tensile ye-PET sheet, Yongeza ixabiso elongezelelweyo--- Ukufuma kokugqibela kunokuba ≤30ppm nge-20minsYomile & Crystallization

- Umgca womatshini uxhotyiswe nge-Siemens PLC inkqubo kunye nomsebenzi omnye obalulekileyo wememori

- Iquka indawo encinci, isakhiwo esilula kwaye kulula ukuyisebenzisa kunye nokugcinwa

- Ukushisa okuzimeleyo kunye nexesha lokumisa libekwe

- Akukho ulwahlulo lweemveliso ezinobunzima obuhlukeneyo

- Ukucoca ngokulula kunye nokutshintsha izinto

>> Umgca womatshini wePET Extrusion

| Umzekelo | Umaleko omninzi | Umaleko omnye | Ukusebenza okuphezulu |

| Inkcazo ye-Extruder | LD75&36/40-1000 | LD75/40-1000 | LD95&62/44-1500 |

| Ukutyeba kwemveliso | 0.15-1.5mm | 0.15-1.5mm | 0.15-1.5mm |

| Amandla enjini aphambili | 110kw/45kw | 110kw | 250kw/55kw |

| Umthamo omkhulu we-extrusion | 500kg/h | 450kg/h | 800-1000kg/h |

Uluhlu lomatshini

| Ukuqulunqwa komatshini | ||

| NO | Umatshini | Ubungakanani |

| 1 | I-PET infrared crystal dryer | Iseti e-1 |

| 2 | Ivacuum isikrufu feeder | Iseti e-1 |

| 3 | I-extruder ephindwe kabini | Iseti e-1 |

| 4 | Vacuum inkqubo yoxinzelelo olubi | Iseti e-1 |

| 5 | Isihluzi setshaneli ephindwe kabini | Iseti e-1 |

| 6 | Yinyibilikisa impompo yokulinganisa | Iseti e-1 |

| 7 | I-PET ngundo ekhethekileyo iyafa | Iseti e-1 |

| 8 | I-Calendering eyimiqulu emithathu iyinxalenye | Iseti e-1 |

| 9 | I-silicone yokugcoba ioli kunye nesixhobo se-Oven | Iseti e-1 |

| 10 | Isixhobo sokusika izinto ze-Edge | Iseti e-1 |

| 11 | Isixhobo sokubuyisela i-Edge | Iseti e-1 |

| 12 | Inkqubo yokujija isikhululo esiphindwe kabini | Iseti e-1 |

| 13 | SIEMENS inkqubo yokulawula ujongano lomatshini wobuntu | Iseti e-1 |

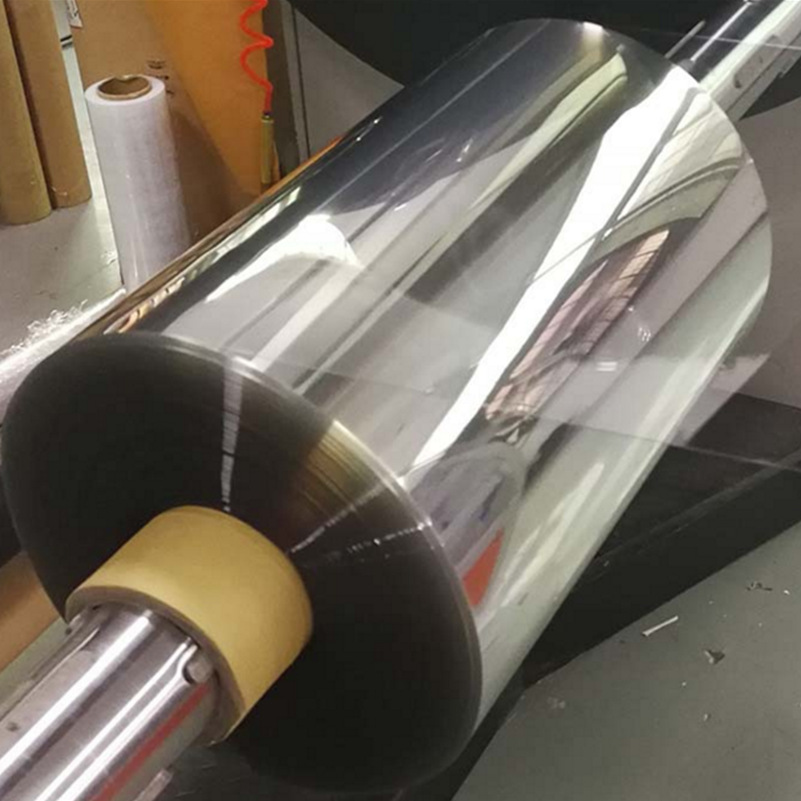

Iifoto zoomatshini

FAQ

Umbuzo: Ngowuphi ukufuma kokugqibela onokukufumana? Ngaba unawo nawuphi na umda ekunyakameni kokuqala kwemathiriyeli ekrwada?

A: Umswakama wokugqibela esinokuwufumana ≤30ppm (Thatha i-PET njengomzekelo). Ubumanzi bokuqala bunokuba yi-6000-15000ppm.

Q: Sisebenzisa i-Double parallel screw extruding nge-vacuum degassing system ye-PET Sheet extrusion, ngaba kuya kufuneka sisebenzise i-pre-dryer?

A: Sicebisa ukuba usebenzise i-pre-dryer ngaphambi kokukhutshwa. Ngokuqhelekileyo inkqubo enjalo ineemfuno ezingqongqo kumswakama wokuqala we-PET. Njengoko sisazi ukuba i-PET luhlobo lwemathiriyeli enokufunxa ukufuma kwi-atmosfera eya kubangela ukuba umgca we-extrusion usebenze kakubi. Ke sicebisa ukuba usebenzise isomisi sangaphambili phambi kwenkqubo yakho ye-extrusion:

>> Ukunciphisa ukuthotywa kwe-hydrolytic ye-viscosity

>>Thintela ukunyuka kwamanqanaba e-AA kwizinto ezinoqhagamshelwano lokutya

>> Ukwandisa umthamo wemveliso ukuya kuthi ga kwi-50%

>> Uphuculo kwaye wenze umgangatho wemveliso uzinze-- Ukulingana kunye nokuphinda-phinda isiqulatho sokufuma kwesixhobo

Umbuzo: Siza kusebenzisa imathiriyeli entsha kodwa asinawo amava okomisa loo mathiriyeli. Ngaba ungasinceda?

A: Umzi-mveliso wethu uneZiko loVavanyo. Kwiziko lethu loVavanyo, sinokwenza umfuniselo oqhubekayo okanye oyekiweyo wemathiriyeli yesampulu yabathengi. Izixhobo zethu zibonelelwe ngetekhnoloji ebanzi yokuzenzekela kunye nokulinganisa.

Singabonisa --- Ukuhambisa / ukuLayisha, Ukomisa & Crystallization, Ukukhupha.

Ukomisa kunye ne-crystallization yezinto eziphathekayo ukumisela ukufuma okushiyekileyo, ixesha lokuhlala, igalelo lamandla kunye nezinto eziphathekayo.

Singakwazi kwakhona ukubonisa intsebenzo ngokukhupha iibhetshi ezincinci.

Ngokuhambelana neemfuno zakho zemathiriyeli kunye nemveliso, sinokwenza imephu yesicwangciso kunye nawe.

Injineli enamava iya kwenza uvavanyo. Abasebenzi bakho bayamenywa ukuba bathathe inxaxheba kwiindlela zethu ezidibeneyo. Ke ngoko ninako kokubini ukuba negalelo elibonakalayo kunye nethuba lokubona iimveliso zethu zisebenza.

Umbuzo: Liliphi ixesha lokuhanjiswa kwe-IRD yakho?

A: Iintsuku zokusebenza ezingama-40 ukusukela oko sifumene idiphozithi yakho kwiakhawunti yenkampani yethu.

Umbuzo: Kuthekani ngofakelo lwe-IRD yakho?

Injineli enamava inokunceda ukufakela inkqubo ye-IRD kumzi-mveliso wakho. Okanye sinokubonelela ngenkonzo yesikhokelo kwi-intanethi. Umatshini wonke wamkela iplagi yokubhabha, kulula ukuyidibanisa.

Umbuzo: Yeyiphi i-IRD enokwenzelwa yona?

A: Inokuba pre-dryer for

PET/PLA/TPE Sheet extrusion line line

I-PET Bale intambo yokwenza umgca womatshini

I-PET masterbatch crystallization kunye nokomisa

PETG Sheet umgca extrusion

Umatshini we-PET monofilament, i-PET monofilament extrusion line, i-PET monofilament yomtshayelo

I-PLA / PET Umatshini wokwenza ifilimu

PBT, ABS / PC, HDPE, LCP, PC, PP, PVB, WPC, TPE, TPU, PET (Bottleflakes, granules, flakes), PET masterbatch, CO-PET, PBT, PEEK, PLA,PBAT, PPS njl.

Iinkqubo zokushisa zeukususwa kwe-oligomeren yokuphumla kunye namacandelo aguquguqukayo.