I-Desiccant Desiccant Dehumidifier yepulasitiki

Isampula Yohlelo Lokusebenza

| Impahla eluhlaza | I-PET Pellets (Yenziwe Nge-flake Esenziwe kabusha) |  |

| Ukusebenzisa Umshini | I-LDHW-600*1000 |  |

| Isethi Yokushisa Eyikristalu | 200℃ | |

| Isikhathi se-crystallized sisethiwe | 20 imiz | |

| Okokugcina | I-Crystallized PET Pellets |  |

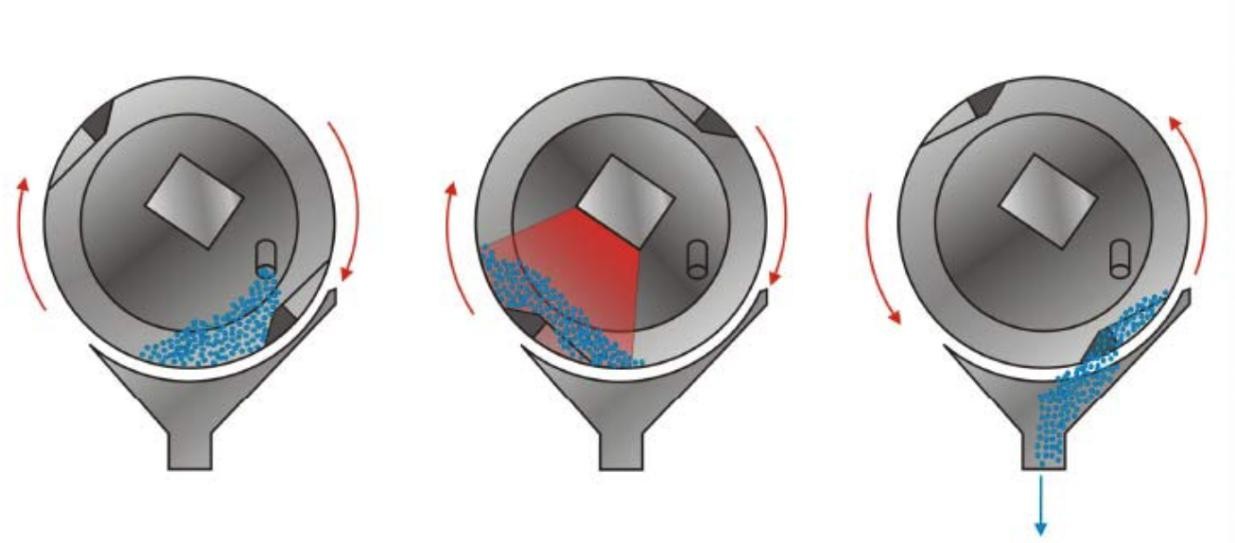

Indlela Yokusebenza

>>Esinyathelweni sokuqala, okuwukuphela kwethagethi ukushisisa okokusebenza kumazinga okushisa asethiwe.

Yamukela isivinini esinensa kakhulu sokuzungezisa isigubhu, amandla amalambu e-Infrared esomisi azoba sezingeni eliphakeme, bese ama-PET pellets azoba nokushisisa okusheshayo kuze kube yilapho izinga lokushisa likhuphukela ezingeni lokushisa elisethiwe.

>>Ukomisa &isinyathelo sokucwebezela

Uma impahla ifika emazingeni okushisa, isivinini sesigubhu sizokwenyuswa siye kwisivinini esiphezulu kakhulu sokuzungeza ukuze kugwenywe ukunqwabelana kwezinto. Ngesikhathi esifanayo, amandla amalambu e-infrared azokwengezwa futhi ukuze aqedele ukomisa. Khona-ke isivinini sokuzungeza isigubhu sizoncishiswa futhi. Ngokuvamile inqubo yokomisa izoqedwa ngemva kwemizuzu engu-15-20. (Isikhathi esiqondile sincike endaweni yezinto)

>>Ngemva kokuqeda ukucutshungulwa kokumisa, i-IR Drum izokhipha ngokuzenzakalelayo okokusebenza futhi igcwalise kabusha isigubhu emjikelezweni olandelayo.

Ukugcwaliswa kabusha okuzenzakalelayo kanye nawo wonke amapharamitha afanelekile wamarempu okushisa ahlukene ahlanganiswe ngokugcwele kusilawuli sesimanjemanje se-Touch Screen. Uma amapharamitha namaphrofayili wokushisa esetholelwe into ethile, izilungiselelo zethisthi zingalondolozwa njengamaresiphi ohlelweni lokulawula.

Inzuzo Yethu

Ukusetshenziswa kwamandla okungafika ku-60% kunesistimu yokomisa evamile

Akukho ukuhlukaniswa kwemikhiqizo enokuminyana kwenqwaba ehlukene

Izinga lokushisa elizimele kanye nesikhathi sokumisa simisiwe

Ukuhlanza okulula nokushintsha impahla

Ukuqalisa okusheshayo nokuvala shaqa ngokushesha

I-crystallization efanayo

Awekho ama-pellets ahlanganayo futhi anamathele

Ukwelashwa ngezinto ezibonakalayo ngokucophelela

Izithombe Zomshini

Isicelo somshini

| Ukushisisa. | Ukushisisa ama-granules nokugaywa kabusha kokubalulekile ngaphambi kokuqhubeka nokucutshungulwa (isb. i-PVC, i-PE, i-PP,…) ukuze kuthuthukiswe ukuphuma kwenqubo ye-extrusion. |

| I-Crystallization | I-Crystallization ye-PET (ama-Bottle flakes, ama-granules, ama-flakes), i-PET masterbatch, i-co-PET, i-PBT, i-PEEK, i-PLA, i-PPS, njll. |

| Ukomisa | Ukomiswa kwama-granules epulasitiki, nezinto eziphansi (isb i-PET, i-PBT, i-ABS/PC, i-HDPE, i-LCP, i-PC, i-PP, i-PVB, i-WPC, i-TPE, i-TPU) kanye nezinye izinto eziyinqwaba ezigeleza mahhala. |

| Umswakama ophezulu wokufaka | Izinqubo zokomisa ezinomswakama ophezulu wokufakwayo > 1% |

| Abahlukahlukene | Izinqubo zokushisa zokukhishwa kwama-oligomers okuphumula kanye nezingxenye eziguquguqukayo. |

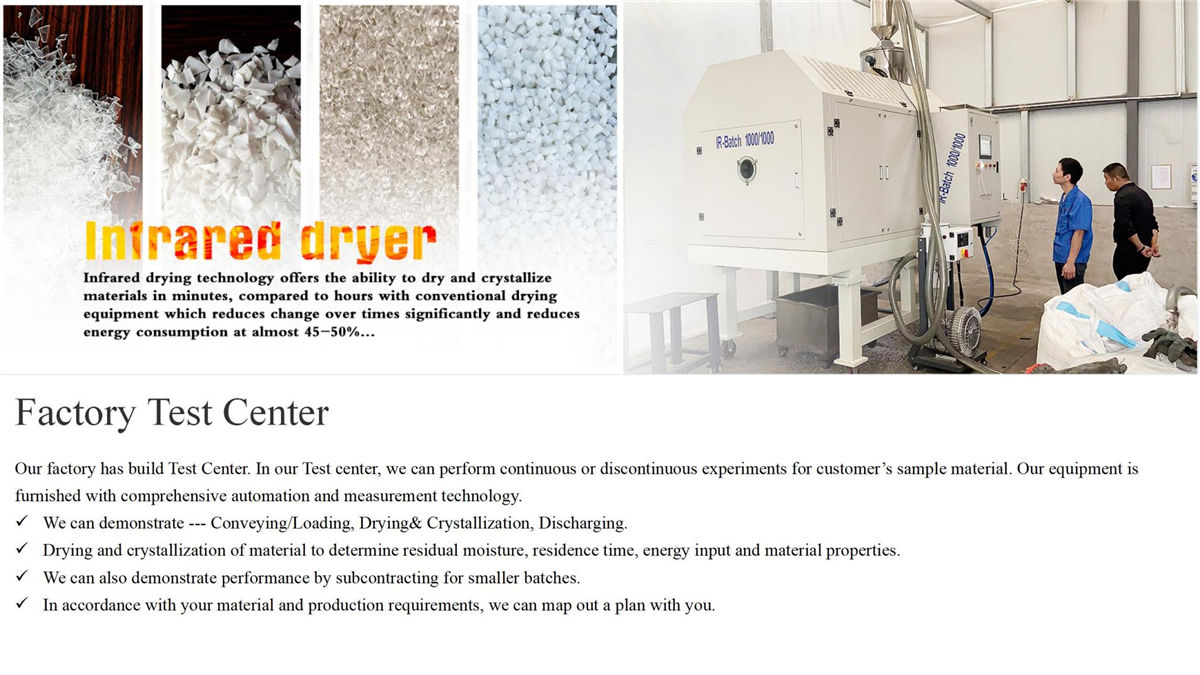

Ukuhlola Okubalulekile Kwamahhala

Unjiniyela onolwazi uzokwenza ukuhlolwa. Abasebenzi bakho bamenywa ngokufudumele ukuthi babambe iqhaza emizileni yethu ehlanganyelwe. Ngakho unakho kokubili ithuba lokunikela ngenkuthalo kanye nethuba lokubona imikhiqizo yethu isebenza.

Ukufakwa komshini

>> Nikeza unjiniyela onolwazi efekthrini yakho ukusiza ukufakwa kanye nokuhlolwa kwempahla kusebenza

>> Yamukela ipulaki yendiza, asikho isidingo sokuxhuma izintambo zikagesi kuyilapho ikhasimende lithola umshini efektri yalo. Ukwenza lula isinyathelo sokufaka

>> Nikeza ividiyo yokusebenza ukuze ifakwe kanye nomhlahlandlela osebenzayo

>> Ukwesekwa on line service