Isomisi se-resin yepulasitiki

Isampula Yohlelo Lokusebenza

| Impahla eluhlaza | I-PET Resin CR-BrightFor iphasela lokudla |  |

| Ukusebenzisa Umshini | I-LDHW-600*1000 |  |

| Umswakama wokuqala | 2210ppmIhlolwe yi-German Sartorius Moisture test instrument |  |

| Isethi Yokushisa Yokumisa | 200℃ | |

| Isikhathi sokumisa simisiwe | 20 imiz | |

| Umswakama wokugcina | 20ppmIhlolwe yi-German Sartorius Moisture test instrument |  |

| Umkhiqizo wokugcina | I-PET Resin Eyomile ayikho i-clumping, awekho ama-pellets anamathelayo |  |

Indlela Yokusebenza

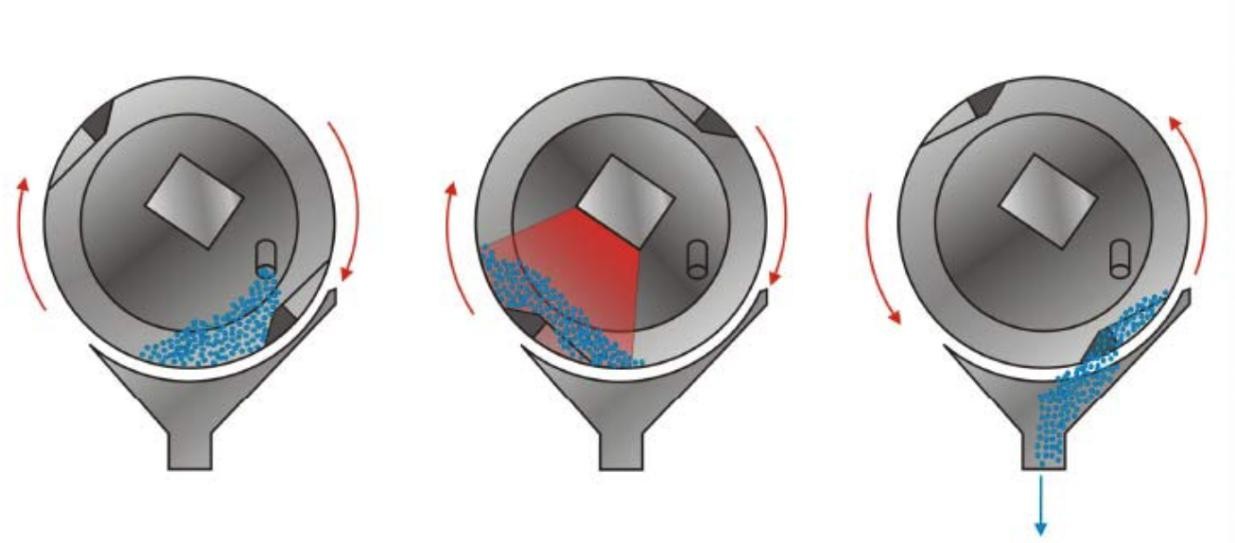

>>Esinyathelweni sokuqala, okuwukuphela kwethagethi ukushisisa okokusebenza kumazinga okushisa asethiwe.

Yamukela isivinini esinensa kakhulu sokuzungezisa isigubhu, amandla amalambu e-Infrared esomisi azoba sezingeni eliphakeme, bese ama-PET pellets azoba nokushisisa okusheshayo kuze kube yilapho izinga lokushisa likhuphukela ezingeni lokushisa elisethiwe.

>>Isinyathelo sokumisa

Uma impahla ifika emazingeni okushisa, isivinini sesigubhu sizokwenyuswa siye kwisivinini esiphezulu kakhulu sokuzungeza ukuze kugwenywe ukunqwabelana kwezinto. Ngesikhathi esifanayo, amandla amalambu e-infrared azokwengezwa futhi ukuze aqedele ukomisa. Khona-ke isivinini sokuzungeza isigubhu sizoncishiswa futhi. Ngokuvamile inqubo yokomisa izoqedwa ngemva kwemizuzu engu-15-20. (Isikhathi esiqondile sincike endaweni yezinto)

>>Ngemva kokuqeda ukucutshungulwa kokumisa, i-IR Drum izokhipha ngokuzenzakalelayo okokusebenza futhi igcwalise kabusha isigubhu emjikelezweni olandelayo.

Ukugcwaliswa kabusha okuzenzakalelayo kanye nawo wonke amapharamitha afanelekile wamarempu okushisa ahlukene ahlanganiswe ngokugcwele kusilawuli sesimanjemanje se-Touch Screen. Uma amapharamitha namaphrofayili wokushisa esetholelwe into ethile, izilungiselelo zethisthi zingalondolozwa njengamaresiphi ohlelweni lokulawula.

Inzuzo Yethu

| 1 | Ukusetshenziswa kwamandla okuphansi | Ukusetshenziswa kwamandla okuphansi ngokuphawulekayo uma kuqhathaniswa nezinqubo ezivamile, ngokwethulwa okuqondile kwamandla e-infrared emkhiqizweni. | |

| 2 | Amaminithi esikhundleni samahora | Umkhiqizo uhlala imizuzu embalwa kuphela enqubweni yokomisa bese utholakala ngezinyathelo ezengeziwe zokukhiqiza. | |

| 3 | Ngokushesha | Ukuqaliswa kokukhiqiza kungaqala ngokushesha lapho kuqala. Isigaba sokufudumala somshini asidingeki. | |

| 4 | Ngomusa | Izinto ezisetshenziswayo zishisiswe kahle kusuka ngaphakathi kuye ngaphandle futhi azilayishwa ngaphandle amahora amaningi ngokushisa, futhi ngaleyo ndlela zonakaliswe. | |

| 5 | Ngesinyathelo esisodwa | I-Crystallization kanye nokomisa ngesinyathelo esisodwa | |

| 6 | Ukwengeza okuphumayo | Ukwenyuka kokuphuma kwezitshalo ngokunciphisa umthwalo ku-extruder | |

| 7 | Akukho ukugoqa, akukho ukunamathela | Ukuzungezisa isigubhu kuqinisekisa ukunyakaza okungaguquki kwempahla.Amakhoyili asondekile kanye nezinto ezixutshwayo eziklanyelwe umkhiqizo wakho ziqinisekisa ukuxutshwa okuphelele kwezinto futhi kugwema ukunqwabelana. Umkhiqizo ushiswe ngokulinganayo | |

| 8 | Isilawuli se-Siemens PLC | Lawula.Idatha yenqubo, efana nezinga lokushisa lomoya obalulekile kanye nokukhipha umoya noma amazinga okugcwalisa agadwa ngokuqhubekayo kusetshenziswa izinzwa nama-pyrometer. Ukuchezuka kubangela ukulungiswa okuzenzakalelayo.Ukukhiqiza kabusha.Izindlela zokupheka kanye nemingcele yenqubo ingagcinwa kusistimu yokulawula ukuze kuqinisekiswe imiphumela emihle futhi ekwazi ukukhiqiza kabusha.Ukugcinwa kwesilawuli kude.Isevisi ye-inthanethi ngemodemu. | |

| 9 | Isikhathi sokumisa sidinga kuphela i-20mins, umswakama wokugcina ungaba ≤ 30ppm | Imisebe ye-infrared engena futhi ibonise kusuka ezintweni ayithinti inhlangano yezinto ezibonakalayo, kodwa izicubu ezimuncwe zizoguqulwa zibe amandla okushisa ngenxa yokuqhuma kwamangqamuzana, okubangela ukuthi izinga lokushisa lempahla likhuphuke. | |

| 10 | Akukho ukugoqa, akukho ukunamathela | Ukuzungezisa isigubhu kuqinisekisa ukunyakaza okungaguquki kwempahla.Amakhoyili asondekile kanye nezinto ezixutshwayo eziklanyelwe umkhiqizo wakho ziqinisekisa ukuxutshwa okuphelele kwezinto futhi kugwema ukunqwabelana. Umkhiqizo ushiswe ngokulinganayo | |

| 11 | Ukuhlanza okulula nokushintsha impahla | Ukufinyelela kahle kuzo zonke izingxenye kuvumela ukuhlanza okulula nokusheshayo.Ukushintsha umkhiqizo ngokushesha. | |

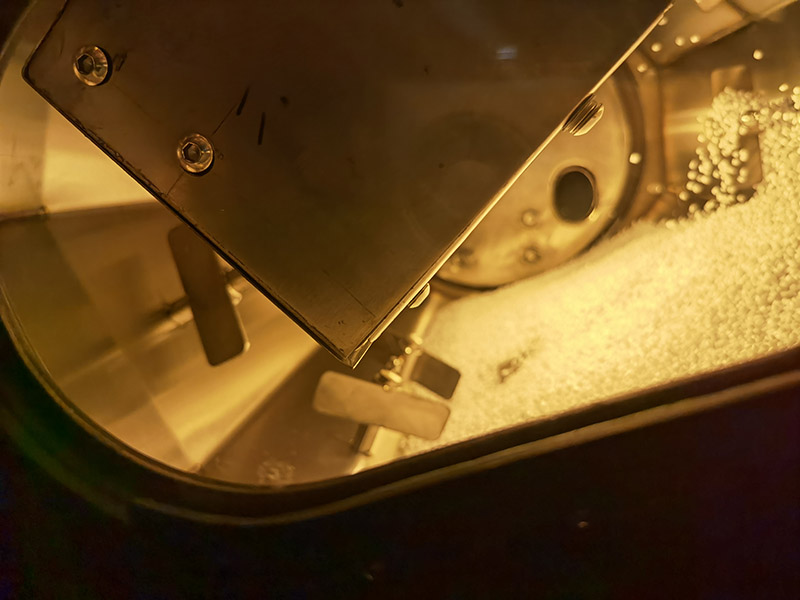

Izithombe Zomshini

Isicelo somshini

Ukomisa Ukomiswa Kwezinhlamvu zepulasitiki (i-PET, i-TPE, i-PETG, i-APET, i-RPET, i-PBT, i-ABS/PC, i-HDPE, i-LCP, i-PC, i-PP, i-PVB, i-WPC, i-TPU njll) kanye nezinye izinto eziyinqwaba ezigeleza mahhala

I-Crystallization PET (i-Bottle flakesm granulates, sheet scrap), i-PET Masterbatch, i-CO-PET, i-PBT, i-PEEK, i-PLA, i-PPS njll.

I-Thermal Ehlukahlukene icutshungulwe ukuze kususwe i-oligomeren yokuphumula kanye nezingxenye eziguqukayo

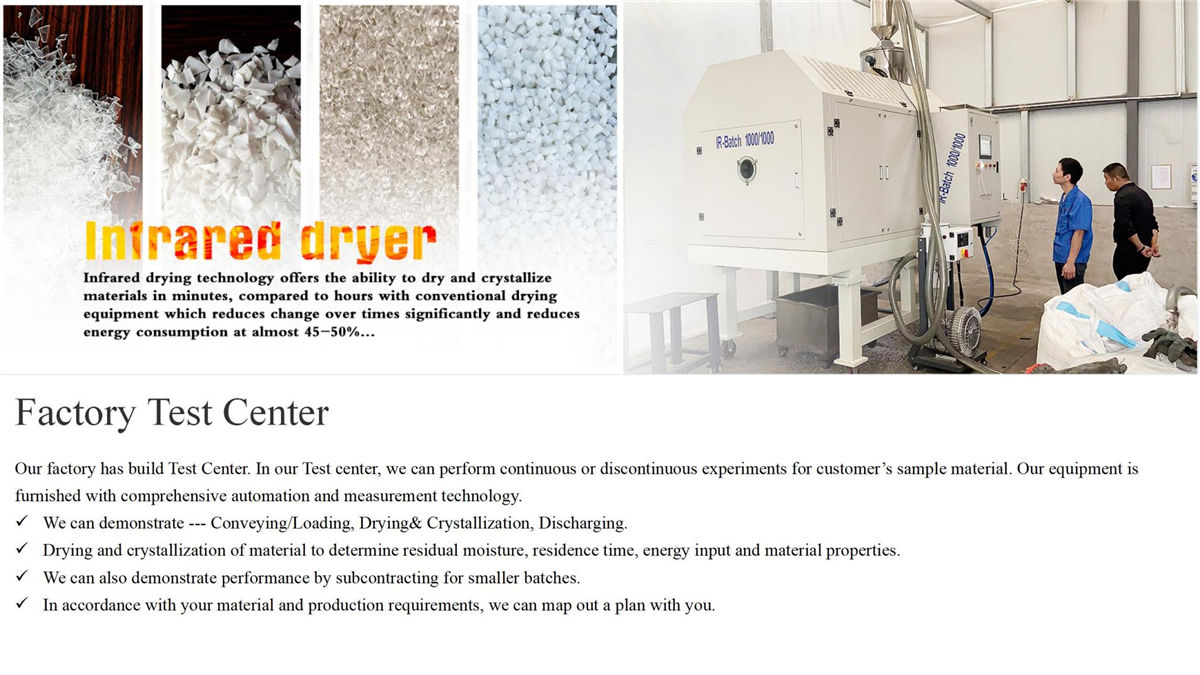

Ukuhlola Okubalulekile Kwamahhala

Unjiniyela onolwazi uzokwenza ukuhlolwa. Abasebenzi bakho bamenywa ngokufudumele ukuthi babambe iqhaza emizileni yethu ehlanganyelwe. Ngakho unakho kokubili ithuba lokunikela ngenkuthalo kanye nethuba lokubona imikhiqizo yethu isebenza.

Ukufakwa komshini

>> Nikeza unjiniyela onolwazi efekthrini yakho ukusiza ukufakwa kanye nokuhlolwa kwempahla kusebenza

>> Yamukela ipulaki yendiza, asikho isidingo sokuxhuma izintambo zikagesi kuyilapho ikhasimende lithola umshini efektri yalo. Ukwenza lula isinyathelo sokufaka

>> Nikeza ividiyo yokusebenza ukuze ifakwe kanye nomhlahlandlela osebenzayo

>> Ukwesekwa on line service